It includes the intelligent drone inspection, land-based rovers and other ground vehicles with AI tools running on mobile devices and smart sensors to enable a safe evaluation of critical assets. Rather than performing slow, manual checks, the technology leverages automated drone inspection and computer vision to collect aerial, ground and close-up data with maximum accuracy. AI built in then processes images, videos and sensor data to spot cracks, corrosion, leaks or hotspots or structural weakness early.

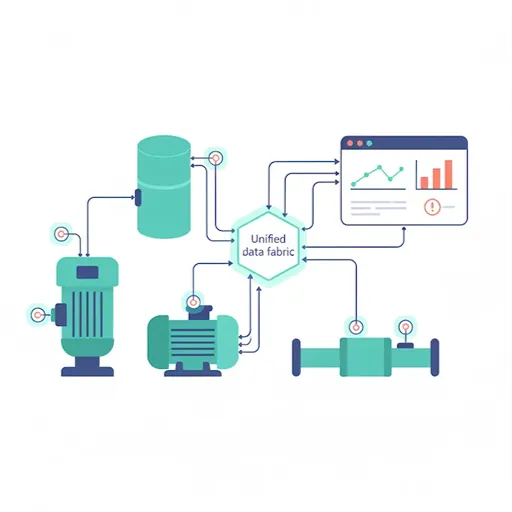

Through aerial inspection combined with sensor fusion and predictive analytics, organizations achieve real-time visibility of their pipelines, power lines, bridges, wind turbines, job sites and other critical infrastructure. This intelligent, data-informed method is safer, minimizes downtime, and can provide repeatable inspections that are audit ready system wide.