Where AI Meets IoT for Relentless Reliability.

A unified APM concept that fuses IoT sensing, edge intelligence, and cloud AI to predict failures, automate actions, and raise overall equipment effectiveness.

A unified APM concept that fuses IoT sensing, edge intelligence, and cloud AI to predict failures, automate actions, and raise overall equipment effectiveness.

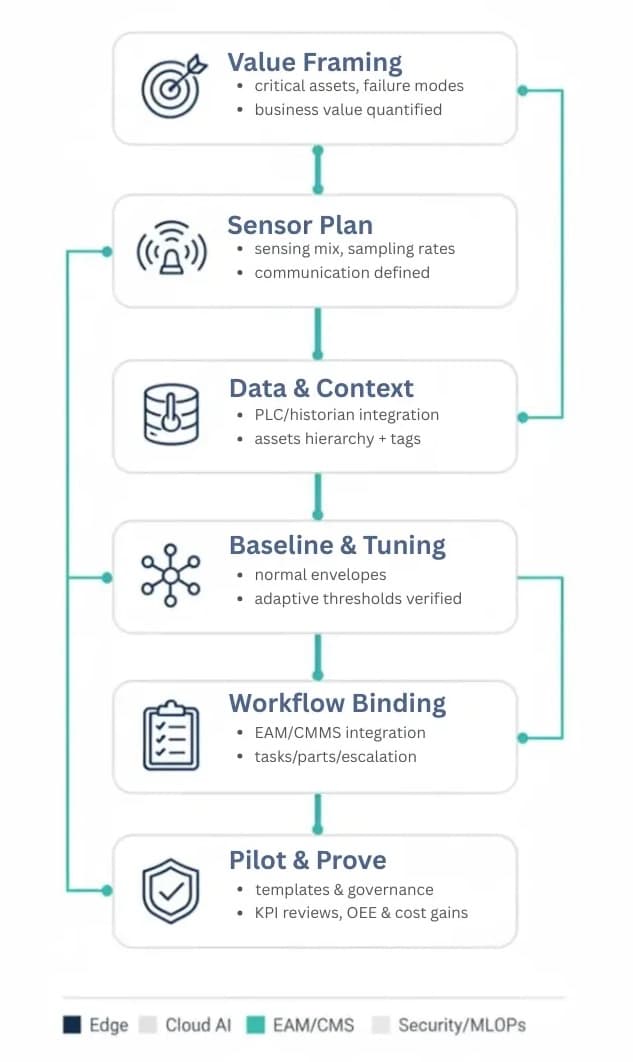

Traditional asset performance management focuses on dashboards and alarms. AI + IoT enabled APM turns every asset into a living data source. Sensors stream vibration, temperature, power, pressure, acoustics, and imagery to edge gateways that run rapid anomaly screening. Cloud models learn fleet patterns, estimate Remaining Useful Life (RUL), and recommend actions. PETRAN orchestrates this edge‑to‑cloud loop, so maintenance becomes proactive, evidence‑driven, and scalable.

IoT turns every pump, motor, and line into a live signal. With PETRAN, wired and wireless sensors stream vibration, temperature, power, pressure, and vision data to the edge for instant anomaly screening then up to the cloud for fleet-wide context. The result: real-time visibility, fewer surprises, and right-time interventions that protect throughput and OEE.

AI elevates monitoring into foresight. PETRAN's cloud models learn asset and fleet patterns, classify failure modes, and estimate Remaining Useful Life to trigger guided work orders. You get risk-scored, evidence-backed recommendations that cut downtime, reduce maintenance costs, and continuously improve with technician feedback.

Reliability‑driven maintenance (RCM/RBI) and predictive maintenance models catch early degradation, preventing costly unplanned downtime.

Shift from time‑based to condition‑based tasks, consolidating work orders and parts usage for measurable cost savings.

Stable assets reduce scrap, micro‑stops, and rework; capacity rises and OEE improves with the same footprint.

Evidence‑ready histories, model explainability, and policy compliance aligned to ISO 55000 and ISA/IEC standards.

Normalize vibration, acoustics, thermal, electrical, pressure/flow, oil quality, speed/load, vision, and environmental data across OPC-UA, Modbus/TCP, MQTT, and REST so every asset becomes a reliable signal source.

Perform on-device feature extraction (enveloping, kurtosis, harmonics), no-motion/shock detection, and first-line anomaly flags at the gateway to deliver sub-second alerts even during cloud outages.

Use fleet-level models to detect subtle performance drift, classify common failure modes, and forecast Remaining Useful Life to move maintenance from reactive to predictive.

Maintain a living model of each asset including duty cycles, setpoints, process states, and work history to sharpen diagnostics, reduce false positives, and prioritize what matters.

Turn risk-scored alerts into guided work orders with recommended tasks, tools, and parts. Technician feedback flows back to improve models and standard operating procedures.

Sequence interventions by risk, criticality, and RUL windows rather than calendars. Align labor, spares, and planned downtime to maximize availability and OEE.

Track versions, monitor drift, and roll back safely. Enforce RBAC/SSO, audit trails, and encryption in transit/at rest. Deploy in cloud, on-prem, or private VPC with the same controls.

Connect to historians, PLC/DCS systems, IoT platforms, and data lakes via open APIs. Keep data where it lives while enabling custom analytics, dashboards, and automation with minimal friction.

PETRAN translates raw IoT signals and AI insights into a concise set of KPIs that operators, reliability engineers, and executives can act on immediately. From Asset Health and Alarm Precision to RUL, OEE impact, and maintenance economics, every metric is traceable back to the evidence sensor features, events, and work history so you can see why performance is trending and what to do next. Dashboards update in real time, reports schedule automatically, and drill-downs link directly to guided work orders, closing the loop between insight and outcome.

Track a single, normalized score per asset that blends vibration, thermal, electrical, and process context. Trend AHI over time, set target bands by criticality, and drill down to the root features driving degradation.

Measure true positives vs. noise to keep operators focused. Report precision/recall, time-to-detect, and alert confidence; flag sensors or models that need recalibration to sustain high signal-to-noise.

Quantify reliability across lines, sites, and asset classes. Slice MTBF by operating mode, workload, and environment to identify where design changes or preventive tasks will yield the biggest reliability lift.

Expose delays from first alert to restoration. Break MTTR into diagnosis, parts wait, and execution time; surface bottlenecks and standardize fixes with guided procedures to accelerate recovery.

See risk-scored failure probabilities with Remaining Useful Life ranges and confidence intervals. Prioritize interventions by risk and window width, and simulate the impact of deferring or advancing work.

Tie condition insights to production outcomes. Attribute OEE losses to specific assets and failure modes, and verify improvements as predictive tasks reduce unplanned downtime and micro-stops.

Track maintenance spend normalized by throughput (₹/unit, $/ton, $/MWh). Compare planned vs. unplanned cost, labor vs. parts mix, and demonstrate ROI as predictive actions shift costs from reactive to planned.

Monitor completion rates, SLA adherence, and the usefulness of technician feedback. Score work orders on evidence quality (photos, vibration captures, notes) and loop the best inputs back into model retraining and SOPs.

An end-to-end sensor and communications stack engineered for premium APM applications: deterministic data capture at the edge, robust telemetry over constrained links, and secure ingestion for real-time analytics and model feedback without naming or depending on any single vendor.

Tri-axial MEMS/IEPE sampling (up to kHz rates) with on-node FFT/enveloping, configurable duty cycles, hardware time-sync (±1–5 ms), and edge compression. IP66/67, intrinsic-safe variants. Secure provisioning and OTA firmware.

Radiometric IR arrays or single-point pyrometers with emissivity correction, spot-size calibration, and region-of-interest alarms. Supports periodic snapshots and delta-T analytics for electrical panels and rotating elements.

Class A PQ meters capturing V/I RMS, THD, harmonics, flicker, phase imbalance, inrush, and transient events with sub-cycle resolution. Synchronized timestamps for correlation with mechanical anomalies and trips.

Smart transmitters (HART/Modbus) providing absolute/differential pressure, flow (DP, vortex, mag), and derived cavitation/clog indices. Includes temperature/viscosity compensation and diagnostic status bits.

Inline viscosity, dielectric constant, moisture (ppm), ferrous particle counts, and ISO code estimations. Edge fusion with vibration bands for bearing/gear mesh degradation scoring.

Multi-protocol I/O (OPC-UA, Modbus/TCP, Ethernet/IP, MQTT), hardware TPM, and containerized ML runtimes. On-device feature extraction, anomaly scoring, store-and-forward with back-pressure handling, and local HA failover.

Industrial cameras (global shutter where required) with inference at the edge (ONNX/TensorRT) for belt tracking, steam/leak detection, and surface defect classification. Includes lens distortion correction and lighting normalization.

Low-bandwidth, high-latency-tolerant telemetry profiles with prioritized payloads (alarms > summary > raw), delta encoding, and opportunistic backhaul. Forward error correction and DTLS/TLS for secure transport.

Turn reactive fixes into condition-based work so parts, labor, and overtime spend all trend down.

Spot anomalies early and intervene before they become line-stopping failures.

Keep equipment within healthy operating envelopes so components last significantly longer.

Stabilize processes and cycle times to unlock more output from the same footprint.

Tell us about your challenge - we’re here to help.