Manufacturing

Smarter, Safer, and More Efficient Manufacturing with Ombrulla Boost quality control, reduce downtime, and protect workers with AI visual inspection, APM, and RTLS.

Smarter, Safer, and More Efficient Manufacturing with Ombrulla Boost quality control, reduce downtime, and protect workers with AI visual inspection, APM, and RTLS.

Ombrulla delivers AI- and IoT-powered solutions that enable manufacturers to improve product quality, reduce downtime, and protect workers at scale. From AI Visual Inspection to Agentic AI for decision-making, our platforms future-proof your operations in the evolving manufacturing landscape.

Manufacturing requires consistent quality control across high-volume production. Manual inspections are slow, prone to human error, and can't keep pace with modern production speeds.

High-resolution cameras and sensors inspect products on production lines in real time.

AI algorithms identify surface defects, dimensional errors, and assembly misalignments instantly.

Virtual product replicas allow predictive simulations to ensure reliability before shipment.

Reduces rework, scrap, and warranty claims.

Speeds up inspections without slowing production lines.

Minimizes waste and reduces quality-related expenses.

A smart factory uses Ombrulla's AI to detect microscopic cracks in machine-tooled parts. The defects are flagged before packaging, and a digital twin simulates stress performance to confirm risks. By preventing defective batches from shipping, the manufacturer avoids a costly recall and protects brand reputation.

Manufacturing equipment CNCs, presses, robotics, and automated systems operate continuously where unexpected failures disrupt production schedules and cost thousands per hour. Traditional reactive maintenance approaches lead to costly unplanned downtime and shortened equipment lifecycles.

IoT sensors track temperature, vibration, and operating speed across production machinery.

AI forecasts wear and tear, preventing breakdowns during production runs.

Local devices analyze sensor data instantly for low-latency alerts.

Ensures smoother production cycles with fewer stoppages.

Protects expensive CNCs, presses, and robotics from premature failure.

Reduces unplanned repairs and unnecessary maintenance.

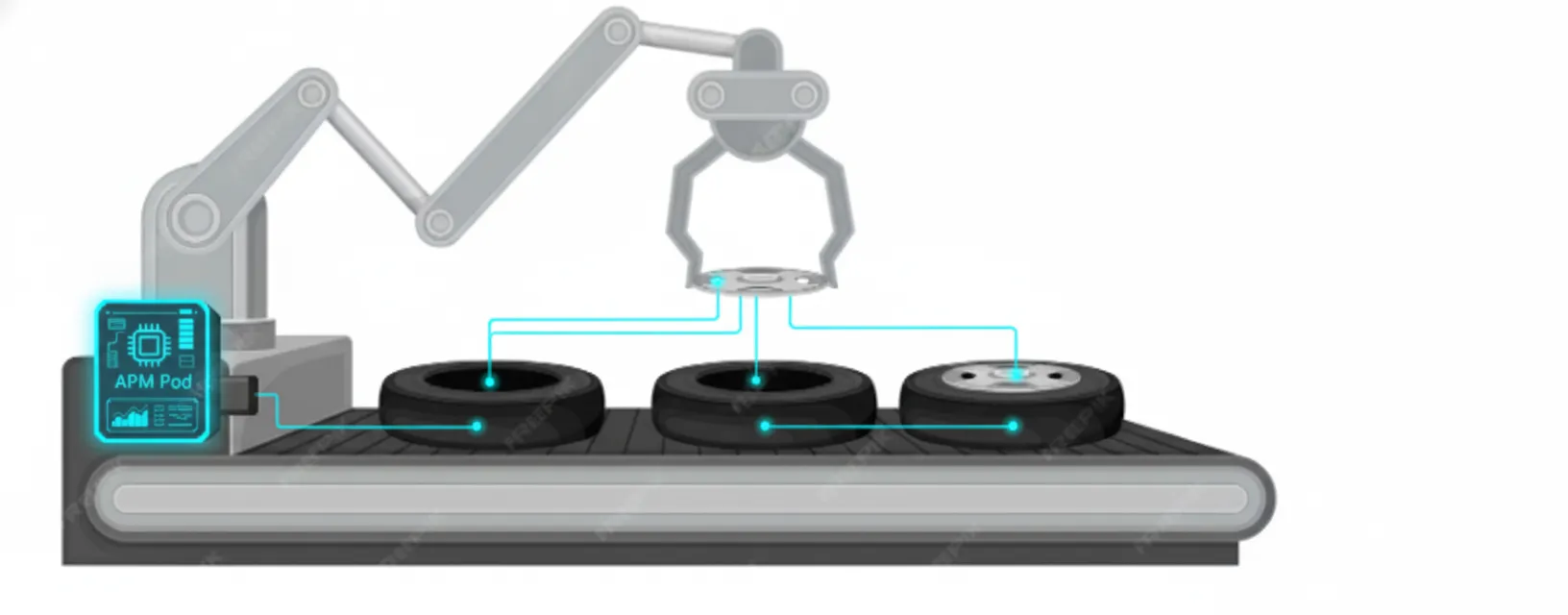

A tire manufacturing plant deploys Ombrulla's APM pods on automated presses. The system detects abnormal heat signatures on one press roller, predicting an impending failure. Maintenance is scheduled during the night shift changeover, preventing a full-day stoppage and saving over $250K in downtime costs.

Manufacturing environments expose workers to moving machinery, hazardous materials, and high-risk zones daily. Traditional safety measures often react too late to prevent accidents.

Smart helmets and badges monitor worker safety, location, and health in real time.

AI-driven geo-zones restrict access to dangerous machinery or zones during operation.

Workers receive instant notifications of overheating machines, chemical leaks, or unsafe behavior.

Prevents accidents and reduces worker compensation claims.

Ensures audit-ready safety logs for OSHA and ISO standards.

Employees trust employers who prioritize safety.

On a factory floor, Ombrulla's wearables detect a worker entering a restricted high-voltage testing zone. The system sends an alert to the worker and simultaneously halts the testing process until clearance is confirmed. The incident is logged automatically, ensuring both safety and compliance.

Modern manufacturing operations generate massive amounts of data from quality control, equipment monitoring, and safety systems. Manual decision-making can't keep pace with the speed required for optimal production performance.

Combines data from inspections, equipment monitoring, and workforce safety into one hub.

Suggests adjustments to production speed, maintenance schedules, or safety protocols.

Implements corrective actions automatically under pre-set policies.

Shortens reaction time to production or safety issues.

AI minimizes mistakes that result from human oversight.

Boosts efficiency, quality, and safety simultaneously.

In an electronics manufacturing plant, Ombrulla's Agentic AI notices rising defect rates in a batch of circuit boards. It recommends slowing the assembly line by 8%, dispatching a maintenance crew to recalibrate soldering robots, and running a defect impact simulation. With one approval, the AI executes the plan protecting output quality while maintaining productivity.

Discover how Ombrulla's intelligent automation can boost quality, reduce downtime, and protect your workforce.