Asset Performance Management: Advanced Asset Monitoring for Maximum Uptime

Traditional asset monitoring methods often rely on manual inspections, periodic maintenance schedules, and reactive problem-solving. While these practices have served industries for decades, they are increasingly inefficient in today’s digitally-driven world. The rise of smart technologies, particularly AI and IoT, offers businesses the opportunity to move from reactive to proactive asset management.

Common Challenges with Traditional Monitoring

• Limited Visibility:

Traditional monitoring often fails to provide continuous real-time data on asset performance, leaving gaps in operational oversight.

• Delayed Problem Detection:

By the time issues are detected, assets may have already sustained significant damage, resulting in costly repairs and downtime.

• Inefficient Resource Use:

Without accurate insights, businesses might spend resources on unnecessary maintenance or miss opportunities to optimize asset utilization.

These challenges underscore the need for more advanced, data-driven solutions like AI-powered and IoT-enabled asset monitoring systems.

The Role of Real-Time Monitoring in Boosting Overall Equipment Effectiveness (OEE):

• Immediate Issue Detection:

Real-time monitoring enables swift identification of equipment malfunctions, which enhances Overall Equipment Effectiveness (OEE) by minimizing downtime through timely interventions.

• Data-Driven Insights:

Continuous data collection from equipment provides actionable insights into performance trends, facilitating effective asset performance management (APM) and informed decision-making to optimize operations.

• Predictive Maintenance:

Monitoring equipment health in real-time allows companies to adopt predictive maintenance strategies that anticipate failures before they occur, thereby reducing unexpected outages and enhancing OEE.

• Enhanced Production Planning:

Real-time data aids in better scheduling and resource allocation, ensuring smooth production processes and maximizing OEE through improved asset utilization.

• Continuous Improvement:

Real-time monitoring supports a culture of continuous improvement by enabling teams to analyze performance metrics and implement changes that lead to increased efficiency in APM.

• Reduced Waste and Costs:

Identifying inefficiencies through real-time monitoring helps in reducing waste, leading to significant cost savings and improved overall profitability, which aligns with the objectives of APM software.

How AI and IoT Elevate Asset Monitoring Capabilities

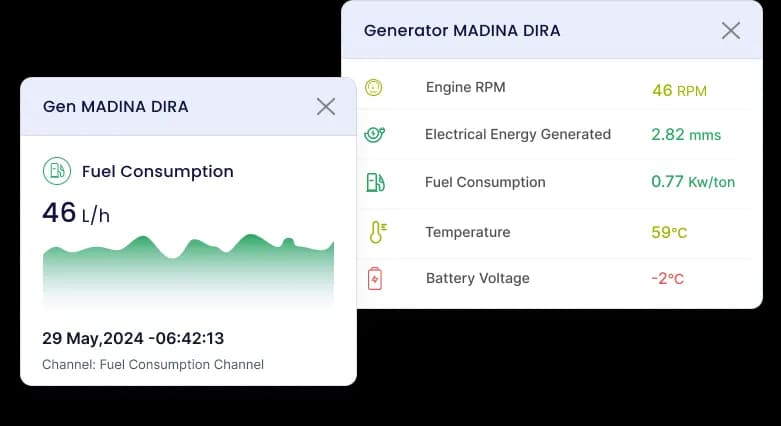

Real-Time Data Collection

IoT enables real-time data collection by linking physical assets to digital networks through sensors. These sensors monitor essential parameters like temperature, pressure, and energy use, allowing continuous updates on asset health. This proactive monitoring helps identify minor issues before they lead to major failures, reducing unexpected downtime and ensuring smooth operations.

AI-Powered Predictive Insights

IoT sensors collect raw data, while AI analyses it to detect patterns and anomalies that indicate potential issues. This predictive analysis allows businesses to anticipate problems and act before failures occur. As a result, predictive maintenance enhances asset longevity, cuts repair costs, and reduces the need for frequent manual inspections, improving efficiency and cost savings.

Customizable Alerts and Automation

AI and IoT-enabled monitoring systems allow for custom thresholds and real-time alerts. When asset performance deviates, immediate notifications are sent to relevant personnel, with some systems enabling automated responses to prevent damage. These alerts help ensure swift action, minimising downtime and preventing accidents or malfunctions.

Enhanced Operational Visibility

AI and IoT provide businesses with real-time visibility through centralised dashboards, replacing manual reports. This continuous insight enables data-driven decisions, enhances efficiency, and optimises resource use. Teams can prioritise critical maintenance tasks and maximise output, supporting smarter overall decision-making.

Key Benefits of AI and IoT-Enabled APM Software

The integration of AI and IoT technologies in asset monitoring is transforming how businesses manage their equipment and resources. These advanced solutions provide real-time visibility, predictive insights, and automated responses, enabling organizations to make data-driven decisions that enhance operational efficiency, safety, and profitability. Below, we explore the key benefits in greater detail:

Reduced Unplanned Downtime

Unplanned downtime can be highly disruptive to operations, leading to significant financial losses, delays, and lower productivity. AI and IoT-enabled asset monitoring offers a proactive solution by continuously tracking the health and performance of critical assets. The data gathered from IoT sensors is processed by AI algorithms that identify potential issues, such as abnormal temperature spikes, vibration patterns, or energy usage, well before they lead to equipment failure.

How It Works:

•With real-time monitoring and AI-powered predictive analytics, businesses can receive early warnings of potential failures. Alerts are triggered when asset performance deviates from predefined thresholds, allowing maintenance teams to address issues before they escalate.Benefit:

• This approach minimizes unplanned downtime, ensuring that operations continue smoothly without unexpected interruptions. Reduced downtime leads to improved productivity, optimized workflows, and ultimately, higher profitability.

Optimized Maintenance Scheduling

Traditional maintenance strategies often follow fixed schedules, leading to either unnecessary maintenance (over-servicing) or untimely repairs (under-servicing). AI and IoT-enabled asset monitoring shifts this model to a more efficient, condition-based maintenance approach, where maintenance activities are scheduled based on real-time asset conditions rather than arbitrary timelines.

How It Works:

•IoT sensors constantly collect data on asset usage, wear-and-tear, and environmental factors. AI analyzes this data to determine when an asset is likely to need maintenance. Instead of routine checks, maintenance is performed only when necessary, based on predictive insights.Benefit:

•Optimized maintenance scheduling reduces the likelihood of asset breakdowns, lowers maintenance costs, and extends the overall lifespan of equipment by avoiding premature or delayed maintenance. It also frees up resources for other critical tasks, improving overall operational efficiency.

Improved Asset Lifespan

The longevity of industrial assets is critical to a company’s bottom line. Equipment that is well-maintained and efficiently utilized will operate longer and more reliably. AI and IoT-based monitoring continuously checks an asset's condition, providing accurate and real-time information about its performance and any emerging issues.

How It Works:

•By detecting early signs of wear, inefficiencies, or small malfunctions, the system ensures that corrective action can be taken before an issue causes significant damage. Regularly monitoring key performance indicators such as temperature, pressure, and energy consumption helps keep assets in optimal working condition.Benefit:

•Prolonging the life of your assets means fewer replacements, lower capital expenditures, and greater return on investment. Assets that are better maintained also perform more efficiently, further enhancing productivity and reducing operating costs over time.

Cost Savings

The ability to predict and prevent asset failures not only reduces downtime but also leads to significant cost savings across various aspects of the business. AI and IoT-based asset monitoring systems help businesses avoid costly repairs, minimize maintenance expenses, and reduce the need for manual inspections.

How It Works:

•By transitioning to predictive maintenance, businesses can avoid the high costs associated with emergency repairs and downtime. With proactive monitoring, the system detects potential issues before they escalate into costly problems. Additionally, optimized resource allocation means that businesses spend less on unnecessary repairs and equipment replacements.Benefit:

•These cost reductions improve profitability and allow companies to reinvest in other areas of the business, such as expansion, innovation, or employee training. The long-term financial savings associated with AI and IoT-enabled monitoring far outweigh the initial investment in technology infrastructure.

Increased Safety

Safety is a top priority in industries that rely on heavy machinery, hazardous equipment, or critical infrastructure. AI and IoT-enabled asset monitoring enhances workplace safety by providing real-time visibility into the health of assets and detecting conditions that could pose a safety risk.

How It Works:

•Sensors track key metrics such as gas leaks, temperature fluctuations, equipment malfunctions, and structural integrity. If a safety hazard is detected, the system can trigger automatic alerts or even shut down equipment to prevent accidents.Benefit:

•Real-time monitoring helps prevent accidents and injuries by detecting dangerous conditions before they cause harm. This creates a safer work environment for employees and reduces the potential for costly liability claims or regulatory fines. A safer workplace also boosts employee morale and can lead to higher productivity.

Industries benefiting from AI and IoT enabled APM Software

While AI and IoT-enabled monitoring are valuable across industries, some sectors stand to gain the most from these technologies:

Manufacturing:

Continuous monitoring of machinery helps avoid production halts and maintain optimal equipment performance. Implementing Asset Performance Management (APM) software enables manufacturers to conduct predictive maintenance, significantly reducing unplanned downtime. Additionally, real-time data analysis enhances overall equipment effectiveness (OEE) by identifying bottlenecks in production processes.

Energy and Utilities:

Monitoring the health of energy assets, such as power lines, turbines, or pipelines, improves efficiency and prevents costly disruptions. APM software facilitates the detection of potential failures, allowing for timely maintenance interventions. This proactive approach not only enhances asset reliability but also contributes to sustainable energy practices by optimizing resource usage.

Transportation and Logistics:

Real-time insights into fleet performance allow companies to optimise routes, reduce fuel consumption, and prevent vehicle breakdowns. Utilising APM solutions helps in tracking vehicle health metrics, ensuring that maintenance is conducted at the right intervals. Furthermore, integrating IoT sensors provides valuable data that aids in improving supply chain efficiency and reducing operational costs.

Infrastructure:

Monitoring structural health in real-time helps prevent major infrastructure failures and ensures the long-term integrity of critical assets like bridges and tunnels. With APM software, infrastructure managers can utilise predictive analytics to foresee potential issues before they escalate, enabling timely repairs. This not only safeguards public safety but also extends the lifespan of vital assets through effective management.

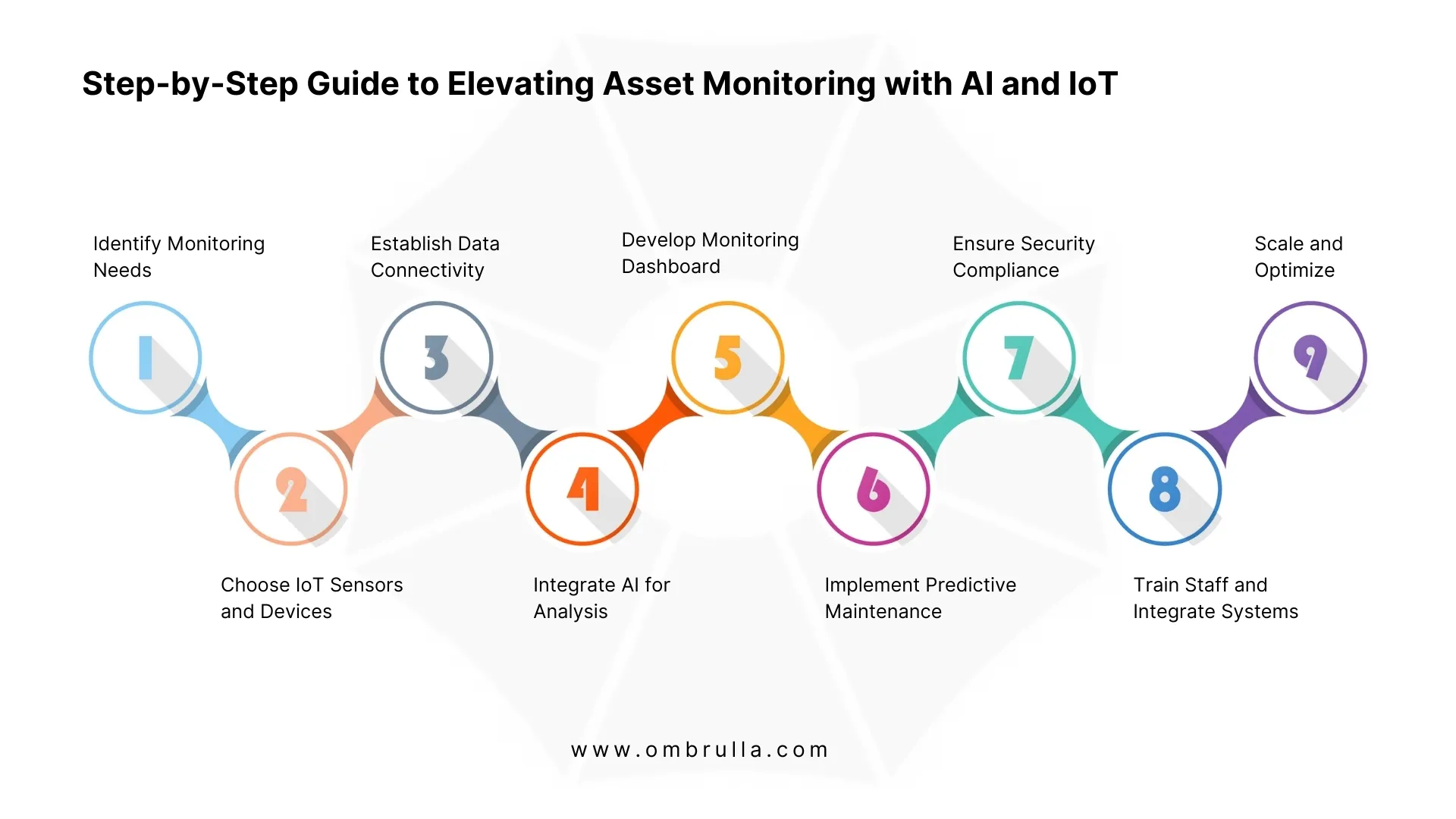

Elevate Asset Monitoring Capabilities with AI and IoT: A Step-by-Step Guide

AI and IoT-powered asset monitoring revolutionise the way businesses manage essential assets by offering real-time insights, predictive analytics, and automated maintenance. It prevents downtime, improves performance, and extends asset lifecycles through proactive management. Businesses can increase productivity and compliance by implementing a consolidated dashboard, enhanced security, and scalable infrastructure. Continuous optimisation provides long-term value and operational excellence.

1. Identify Asset Monitoring Needs and Objectives

Understanding what assets and metrics to focus on ensures the implementation meets your specific business needs.

• Determine assets to monitor:

Pinpoint critical assets that need constant tracking.

• Define monitoring goals:

Set objectives like reducing downtime, optimising performance, or ensuring compliance.

2. Select Appropriate IoT Sensors and Devices

Accurate data collection from relevant sensors is crucial for effective monitoring.

• Choose the right IoT sensors:

Identify sensors to measure temperature, pressure, vibration, etc.

• Install IoT devices:

Deploy hardware to capture real-time data from physical assets.

3. Set Up Data Connectivity and Infrastructure

A stable infrastructure ensures smooth data flow from sensors to AI systems.

• Ensure reliable connectivity:

Use Wi-Fi, 5G, or LPWAN for seamless data transmission.

• Implement edge computing or cloud storage:

Manage data locally or in the cloud based on volume and latency requirements.

4. Integrate AI Algorithms for Data Analysis

AI transforms raw data into actionable insights, helping improve asset performance and prevent breakdowns.

• Apply predictive analytics:

Use AI to forecast asset failures or performance drops.

• Enable real-time data processing:

Analyze data on-the-fly to detect anomalies or inefficiencies.

5. Develop a Centralised Monitoring Dashboard

A user-friendly dashboard helps operators monitor assets easily and act swiftly on any issues.

• Create a real-time dashboard:

Visualize asset health and operational metrics.

• Customize alerts and reports:

Set up automated alerts and reports for key stakeholders.

6. Automate Maintenance with Predictive Maintenance

Predictive Maintenance minimizes unplanned downtime and reduces maintenance costs.

• Schedule maintenance proactively:

Use AI to predict asset failures and schedule repairs before breakdowns occur.

• Optimize maintenance cycles:

Reduce unnecessary maintenance and extend asset life.

7. Ensure Security and Compliance

Ensuring security and compliance is vital to safeguard IoT networks and sensitive asset data.

• Implement robust security measures:

Use encryption and authentication to protect sensitive data.

• Comply with industry standards:

Follow regulatory requirements for data security and operational safety.

8. Train Personnel and Integrate with Existing Systems

Well-trained teams and integrated systems ensure seamless operations and maximize the return on AI and IoT investments.

• Train staff on new tools:

Educate operators on using dashboards, interpreting AI insights, and responding to alerts.

• Integrate with ERP or maintenance systems:

Ensure smooth interoperability with existing business systems.

9. Scale and Optimise Over Time

Scaling and optimization extend the value of AI and IoT-enabled asset monitoring, improving long-term efficiency.

• Expand across more assets or locations:

Scale the system to monitor additional assets or plants.

• Continuously refine AI models:

Optimise algorithms and processes based on real-world data insights.

Conclusion

AI and IoT technologies offer a powerful solution for elevating asset monitoring capabilities. By providing real-time data, predictive insights, and customizable alerts, businesses can stay ahead of equipment failures, reduce downtime, and improve operational efficiency. As industries continue to evolve, AI and IoT will play an increasingly vital role in ensuring that assets are managed proactively and effectively. Embrace these technologies to optimize your asset performance and stay competitive in today’s rapidly changing business landscape.