Boost ROI. Scale AI That Works in the Real World.

From firefighting to foresight: AI that prevents failures before they happen empowering dashboards that convert shop floor data into boardroom innovation and growth decisions.

From firefighting to foresight: AI that prevents failures before they happen empowering dashboards that convert shop floor data into boardroom innovation and growth decisions.

Predict failures early and shift maintenance to planned work.

Drones + AI compress inspection cycles into repair-ready insights.

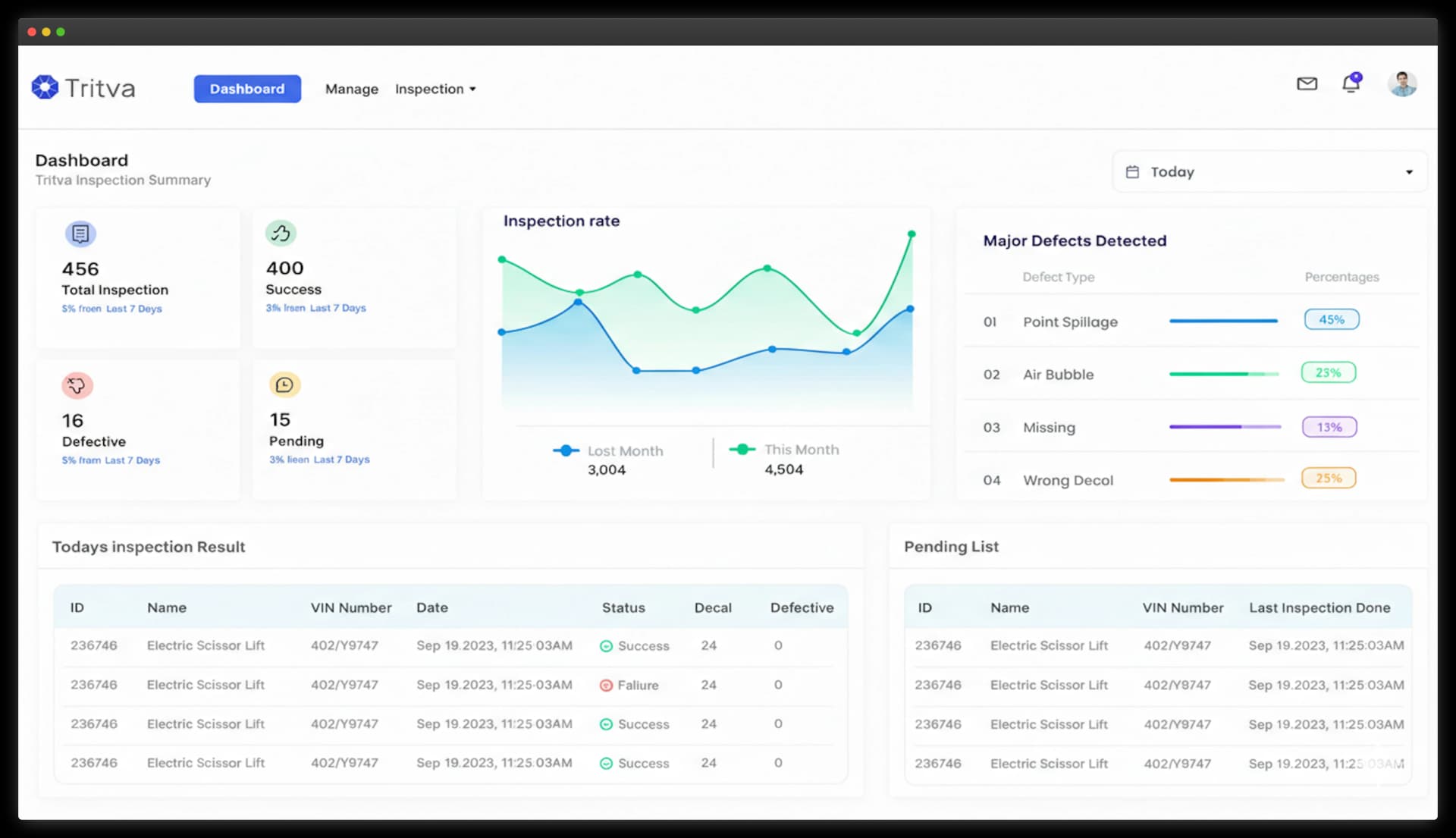

AI vision boosts throughput and catches defects before shipment.

Track workers in hazard zones with real-time alerts and controls.

Most AI programs stall because they don’t fit real industrial constraints data gaps, harsh environments, legacy systems, and adoption hurdles. Ombrulla is built to operationalize AI where it matters: on the shop floor, in the field, and across multi-site operations.

Automated visual inspection across lines and shifts. Real-time alerts + traceability to root cause. Built for variable lighting, speed, and product variance.

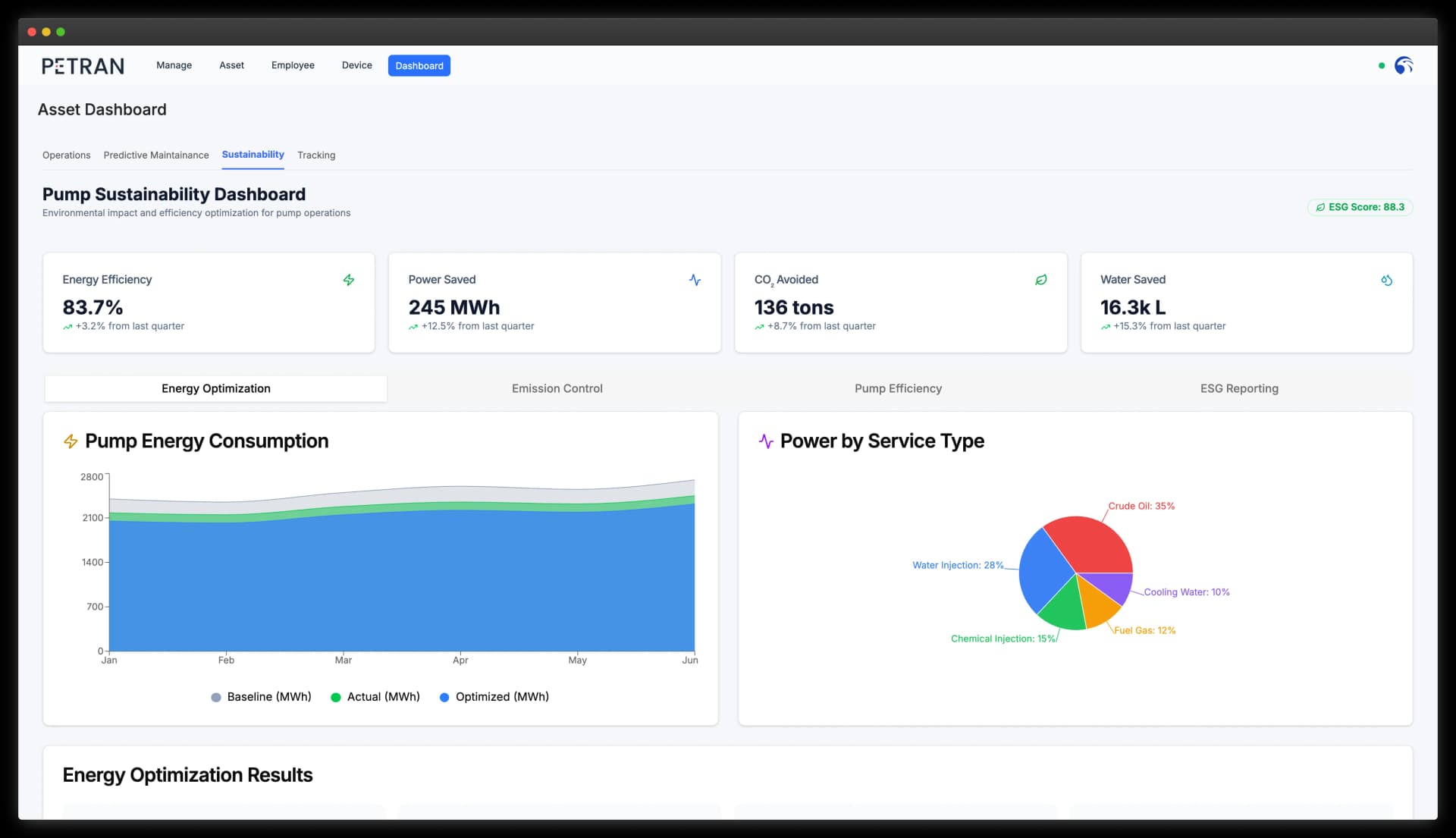

Condition monitoring and predictive alerts for critical assets. Risk-based scheduling to avoid over-maintaining. Higher availability and OEE with fewer breakdowns.

Live worker tracking with hazard-zone geofencing. Alerts for restricted access, exposure, and unsafe proximity. Digital logs for audits, compliance, and incident review.

Rapid pilots for priority use cases with measurable KPIs. Enterprise integration, scalability, and lifecycle support. Responsible, explainable AI for regulated operations.

Drone-based capture for hard-to-access structures. AI-assisted defect identification and condition scoring. Standardized reports to prioritize repairs and budgeting.

See every defect. Ship with confidence. TRITVA uses computer vision to detect defects and anomalies in real time, automating quality checks and reducing escapes without slowing production.

Predict failures. Orchestrate action. Protect uptime. PETRAN combines predictive maintenance and operational intelligence to improve uptime, safety, and compliance, then triggers workflows so teams act before losses occur.

Ombrulla delivers production-grade AI that scales across real operations, fast outcomes, flexible deployment, and enterprise governance built in.

Production-grade AI designed for data gaps, legacy systems, and multi-site execution, so wins in one plant replicate across the network.

Edge, on-prem, cloud, or hybrid, aligned to security, latency, and connectivity requirements in real-world environments.

Outcome-led engagements with clear KPIs, acceptance criteria, and a business case, so value is visible early and defensible at the board level.

Built to plug into your workflows (alerts, work orders, dashboards) with auditability, monitoring, and change control embedded from day one.

Detect corrosion and leaks early, before they become incidents or outages

Standardize field inspections, and accelerate decisions at the point of work

Predict pump failures early, protect uptime and reduce maintenance waste

Tailored AI solutions designed to meet your specific operational needs and drive measurable business value.

Ombrulla solutions help complex enterprises improve safety, reliability, quality, and throughput, at scale. Delivering faster ROI, reduced risk, and consistent performance across every site.

Reduce incidents, improve compliance, prevent asset failures, and maximize production uptime across operations.

Increase throughput and yield, cut defects and rework, and reduce downtime with standardized performance.

Detect risks early, prioritize maintenance, reduce outages, and extend asset life with accurate inspections.

Accelerate line performance, improve quality consistency, reduce scrap, and scale best practices across plants.

Ombrulla's PETRAN uses AI-driven predictive maintenance and APM to anticipate compressor and generator failures, cut downtime, extend asset life, optimize maintenance, and deliver measurable cost savings

Ombrulla's AI turns underwater drone footage into fast, accurate ship inspections cutting risk, downtime, and cost, with unmatched efficiency and reliability.

Ombrulla's AI Data & People Analytics turn hotel CCTV footage into real-time insights on guest behavior, staff performance, and space use elevating customer experience, workforce efficiency, security, and operational excellence.

At Best Western Kansas, Ombrulla's AI turns hotel data into actionable insights boosting guest satisfaction, optimizing resources, and sharpening our edge.

Tell us about your challenge - we’re here to help.