Digital Twin for Smarter, Safer, Always-On Operations

Create a live digital replica of your plants, assets, and processes so you can see what’s happening now, understand why it’s happening, and simulate what happens next.

Create a live digital replica of your plants, assets, and processes so you can see what’s happening now, understand why it’s happening, and simulate what happens next.

Complex operations generate massive streams of data from sensors, machines, and people yet decisions are still often made on static reports and incomplete information. A Digital Twin changes that. It gives you a living, evolving virtual model of your real-world assets and processes. By mirroring your physical environment in a digital space, you can:

Combine real-time condition monitoring with predictive models to foresee failures, schedule interventions in advance, and keep production running reliably.

Use a digital twin to visualise hazardous zones, worker movements, gas readings, and alarms, and run “what-if” incident scenarios without exposing people to risk backed by audit-ready evidence.

Identify bottlenecks, idle time, and rework patterns in the virtual model, test alternative layouts and workflows, and deploy only the best-performing configurations to the physical plant.

Model different energy, utility, and loading strategies in the twin, compare their impact on cost and efficiency, and give all stakeholders a shared, interactive view to shorten debates and time-to-action.

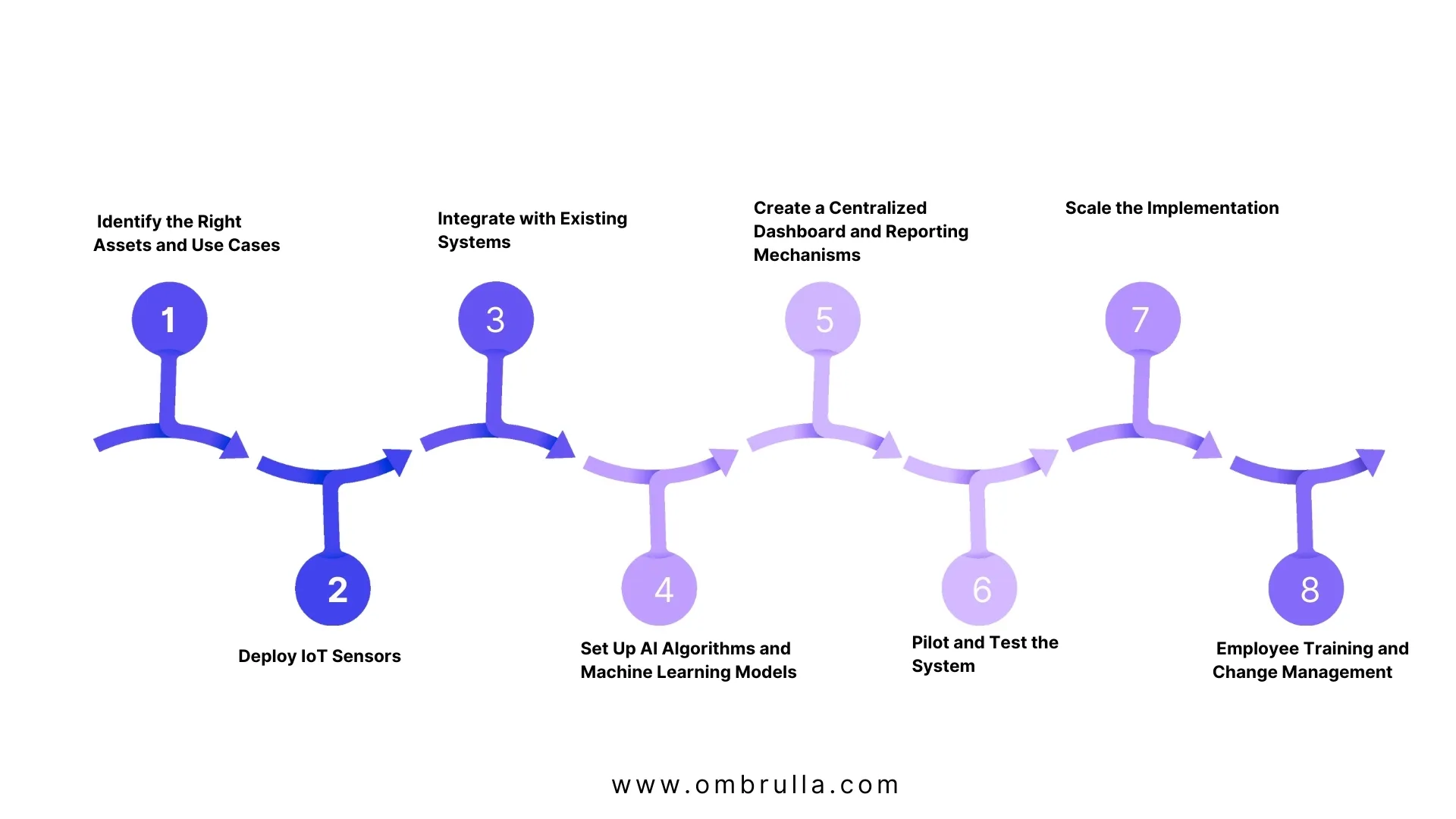

Combine IoT, RTLS, AI, and APM in a single stack for real-time visibility, simulation, and optimisation across your operations.

Integrate current sensors, PLCs, SCADA, MES, ERP, and APM without rip-and-replace or vendor lock-in.

Engineered for harsh environments, multi-site deployments, and strict IT/OT security, with encryption, RBAC, and strong governance.

Field-tested in oil & gas, manufacturing, automotive, and infrastructure focused on uptime, safety, energy, and cost savings, not just 3D visuals.

Our Digital Twin platform combines real-time visualisation, unified data, advanced analytics, and seamless integrations to help industrial teams see, understand, and optimise their operations in one place.

Get an interactive live view of plants, lines, and zones with sensor overlays, alarms, and RTLS positions across sites, floors, and areas, with instant drill-down.

Fuse data from sensors, PLCs, SCADA, RTLS tags, and systems like APM, CMMS, MES, ERP, HRIS, and EHS into a normalised asset hierarchy and single source of truth.

Rewind operations to any point in time to replay states, alarms, and movements, then test different line setups, routing, shifts, maintenance strategies, and emergency scenarios safely in the twin.

Use AI models trained on your operational data to detect anomalies, predict failures and quality issues, recommend optimal setpoints and windows, and feed insights into existing tools via open APIs.

Monitor production performance in real time, across lines and plants. See where WIP is accumulating and why. Test new production plans and routing strategies in the twin.

Monitor production performance in real time, across lines and plants. See where WIP is accumulating and why. Test new production plans and routing strategies in the twin.

Combine asset health, failure history, and operating context. Prioritise work based on real risk and impact, not just static schedules. Visualise access constraints, isolation points, and safe work areas.

Map risk zones, gas detection, and restricted areas in the twin. Simulate emergency response, mustering, and evacuation paths. Maintain an audit-ready record of conditions, actions, and outcomes.

Use the twin to plan expansions, modifications, and shutdowns. Onboard new staff with a realistic, navigable view of the site. Run “table-top” exercises in the virtual environment.

Digital twins of plants, pipelines, and terminals to monitor integrity, assess risk, and plan interventions with full context.

Twins of production lines, utilities, and warehouses to improve throughput, quality, and asset performance.

Detailed line and cell-level twins for robots, conveyors, and stations optimising cycle time, changeovers, and safety.

Site and network-level twins for critical infrastructure, helping teams manage assets, risk, and service continuity.

Ombrulla’s Digital Twin creates a live, virtual replica of your operations combining assets, people, processes, environment, and energy data into one connected, visual model you can explore and optimise.