Tritva

AI Visual Inspection for Quality & Infrastructure

AI Visual Inspection for Quality & Infrastructure

TRITVA strengthens production and infrastructure performance by using AI to catch defects in real time, auto-document issues, and trigger maintenance cutting downtime, improving quality, increasing throughput, and ensuring audit-ready compliance.

TRITVA leverages advanced computer vision to automatically inspect your products and assets from images or video, instantly flagging any defects in real-time and generating comprehensive, audit-ready reports.

Tritva Vision is where inspection intelligence begins. With an intuitive interface for image/video annotation, labeling, and AI model training, enterprises can create custom inspection models tailored to their assets and industry.

Cloud, edge, or hybrid architectures optimized for reliability, cost, and control.

Tritva brings AI-driven visual inspection to your organization cutting costs, reducing errors, and ensuring consistent quality. Easy to integrate and built to scale, it empowers you to stay ahead with confidence.

Enhance efficiency and accuracy in quality control with AI-powered inspection solutions.

AI-powered automated infrastructure inspection for improved safety and efficiency.

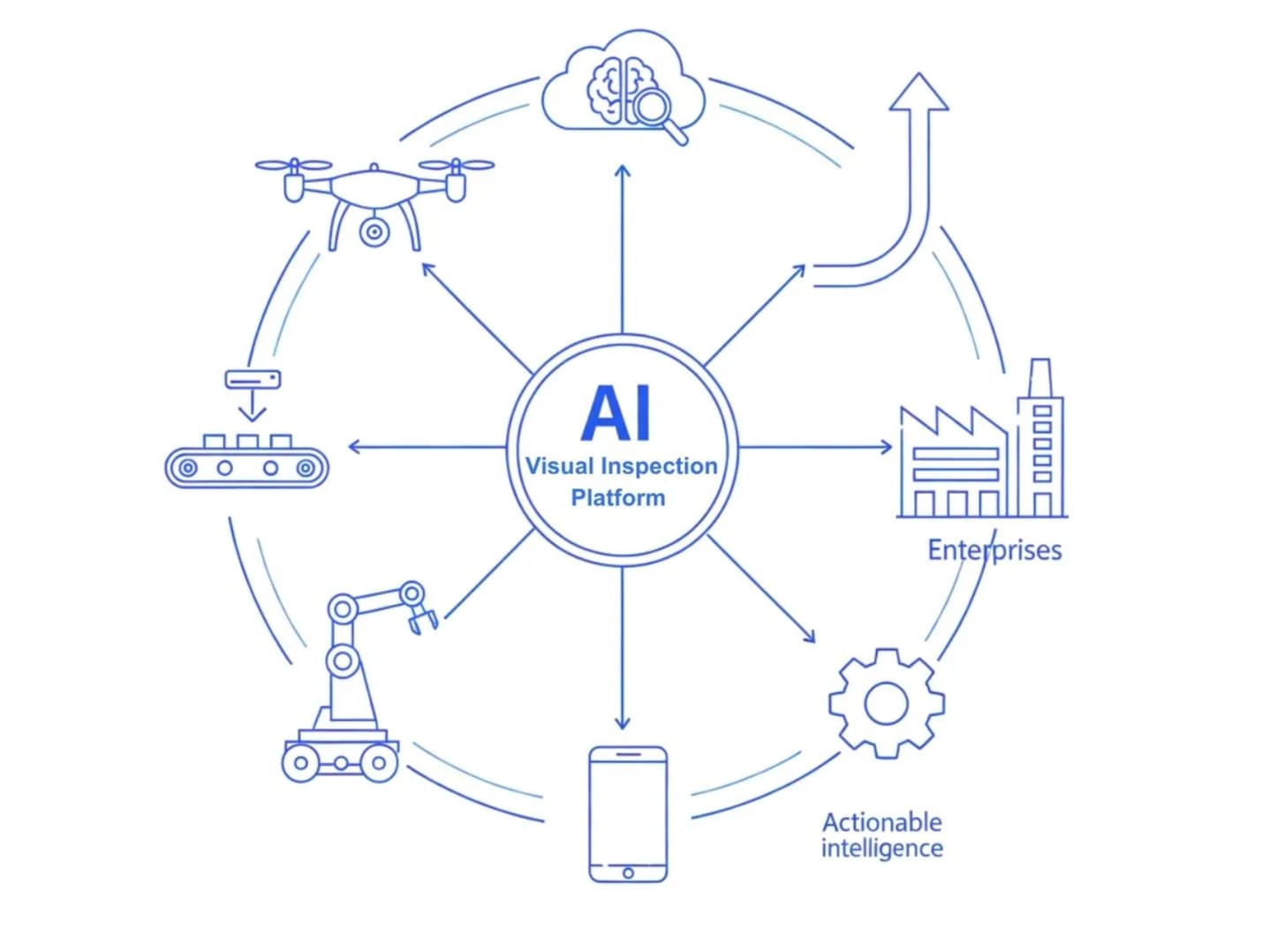

Supports images and videos from drones, rovers, cobots, conveyor AI cameras, and even mobile devices offering unmatched flexibility in inspection.

Instantly analyzes visual data to classify defects, identify exact issues, and ensure zero-delay decision-making on the production floor or in the field.

Works on-premises, in the cloud, or at the edge delivering speed, scalability, and adaptability across industries.

Automatically learns from every inspection, improving accuracy over time and adapting to new defect patterns with minimal human input.

Transforms inspection data into actionable insights with live dashboards and custom reports that help teams improve processes and maintain quality.

Connects effortlessly with ERP, MES, or quality management systems, ensuring inspection results flow directly into business operations.

Built with enterprise-grade security and compliance, safeguarding sensitive data while meeting industry regulations.

From capture to insights, every step ensures accuracy and efficiency.

Collect images & videos via drones, cobots, rovers, conveyor AI cameras, or mobile devices to ensure broad coverage and flexibility.

Book a demo →Collect images & videos via drones, cobots, rovers, conveyor AI cameras, or mobile devices to ensure broad coverage and flexibility.

Book a demo →Tell us about your challenge - we're here to help.