Petran

The AI & IoT Monitoring Platform for Assets, Workers, and Facilities.

The AI & IoT Monitoring Platform for Assets, Workers, and Facilities.

An AI + IoT platform that continuously monitors your assets, workforce, and facilities turning real-time data into faster decisions, fewer incidents, and clear, defensible ROI. With predictive maintenance and live operational intelligence, PETRAN improves uptime, safety, and compliance while lowering cost to serve.

One live map for equipment health, worker safety, and facility status.

Autonomous agents detect patterns, decide, and trigger safe workflows no manual chasing.

Plug in cameras and sensors; use prebuilt skills for common scenarios.

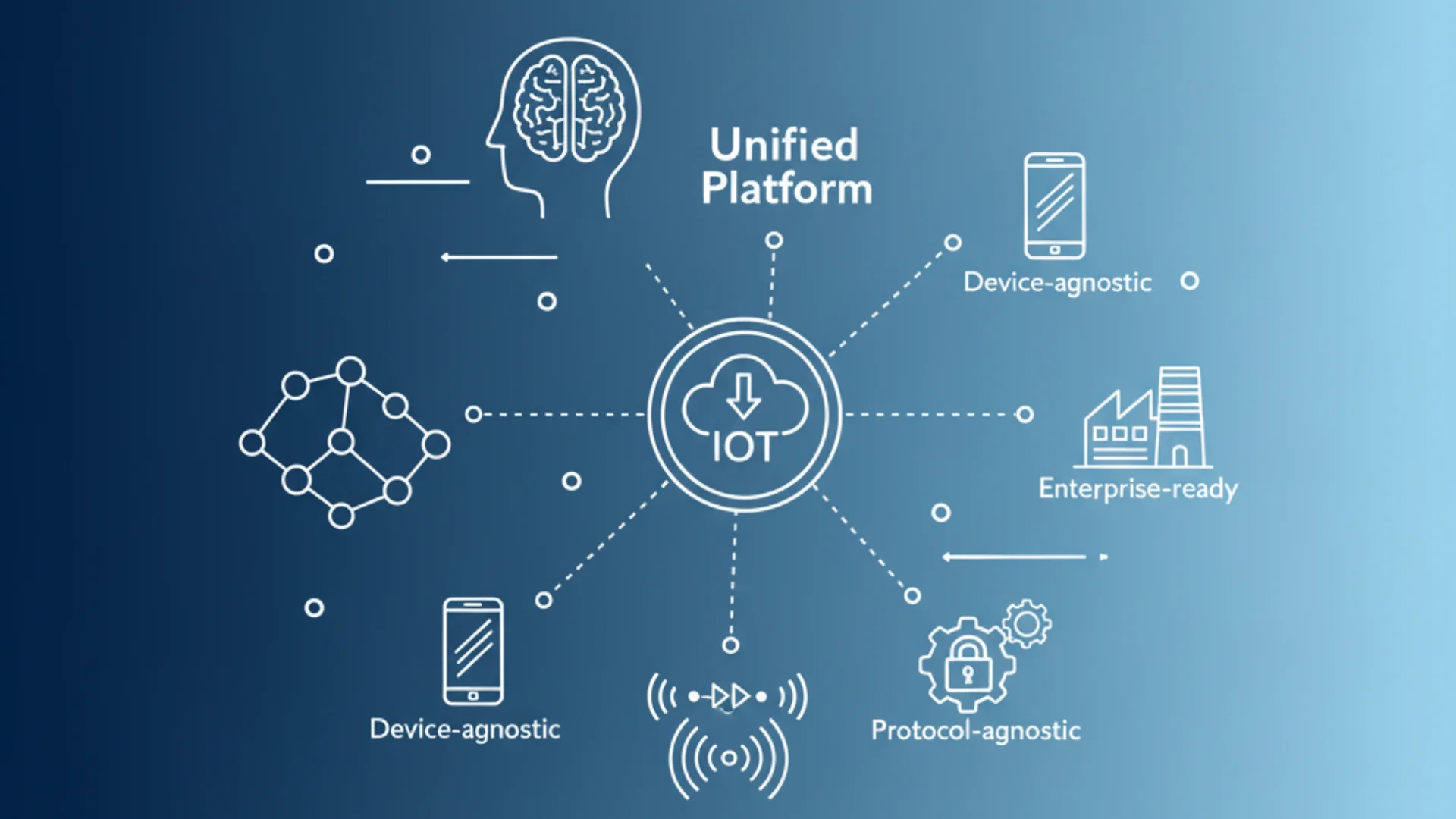

Works with your cameras, PLCs, SCADA, CMMS/EAM, MES, and BMS no vendor lock-in.

Real-time worker safety with PPE detection, posture/motion and zone/permit compliance, lone-worker/man-down and access supervision, plus digital SOPs with guided mobile/edge interventions.

Real-time facility intelligence combining occupancy, environmental and energy monitoring with leak/smoke detection, perimeter and restricted-area security, and a live command center for utilities and process KPIs.

PETRAN brings all your cameras, sensors, and enterprise systems, old and new, into one interoperable, vendor-agnostic platform that speaks open standards and APIs, uses prebuilt connectors, and runs across edge and cloud so you keep your existing investments, avoid lock-in, and get a single, consistent way to act on data across every site.

Fixed/mobile vision, thermal, and hyperspectral cameras for defects, leaks, heat spots, and occupancy.

Visual Detection & Monitoring

Vibration, temperature, and pressure sensors for condition and anomaly detection.

Condition Monitoring

RTLS tags and access control systems to track location, flow, and permissions.

Location & Access Tracking

PLC/SCADA streams and operational logs for context, automation, and auditability.

Operational Intelligence

Bring every camera, sensor, and control system online in minutes. Our edge agents auto-discover devices, normalize data, and keep streaming even with flaky networks.

Everything you need in one place, vision AI, predictive maintenance, worker safety, facility insights, edge + cloud, and plug-and-play integrations, so your teams make faster decisions, reduce risk, and show ROI without ripping out what you already have.

Pre-built skills for defect detection, foreign-object detection, spill/leak, occupancy, PPE & zone compliance; easy model updates no heavy ML lift.

Condition & performance monitoring, failure probability, days-to-failure, and maintenance optimization.

Real-time alerts for slips, trips, falls, near-miss, line-of-fire, and geofenced high-risk areas.

Energy and environment analytics; anomaly detection across HVAC, utilities, and critical rooms.

Run models at the edge for low latency and privacy; orchestrate at scale from a central hub.

Out-of-the-box connectors for major EAM/CMMS (e.g., Maximo), ticketing, data lakes, and message buses.

Versioned models/agents, policy rules, approvals, lineage, and encrypted trails for compliance.

Partitioned data, role-based access, SSO, SCIM, and granular permissions.

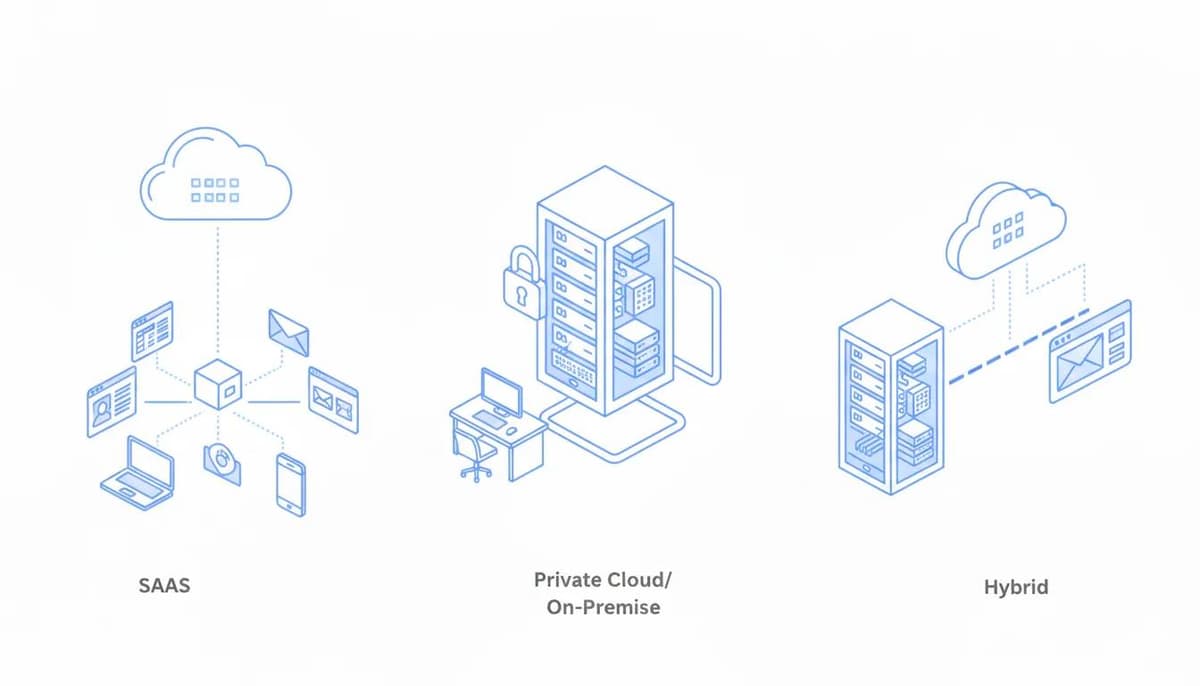

Fastest path to value with enterprise-grade security and zero infrastructure to manage.

Full control for regulated environments hardened, isolated, and compliant.

Low-latency vision and control at the edge with centralized orchestration and policy management.

Tell us about your challenge - we're here to help.