Automotive

Smarter, Safer, and More Efficient Automotive Manufacturing with Ombrulla Enhance quality control, reduce production downtime, and improve worker safety with AI visual inspection, APM, and RTLS.

Smarter, Safer, and More Efficient Automotive Manufacturing with Ombrulla Enhance quality control, reduce production downtime, and improve worker safety with AI visual inspection, APM, and RTLS.

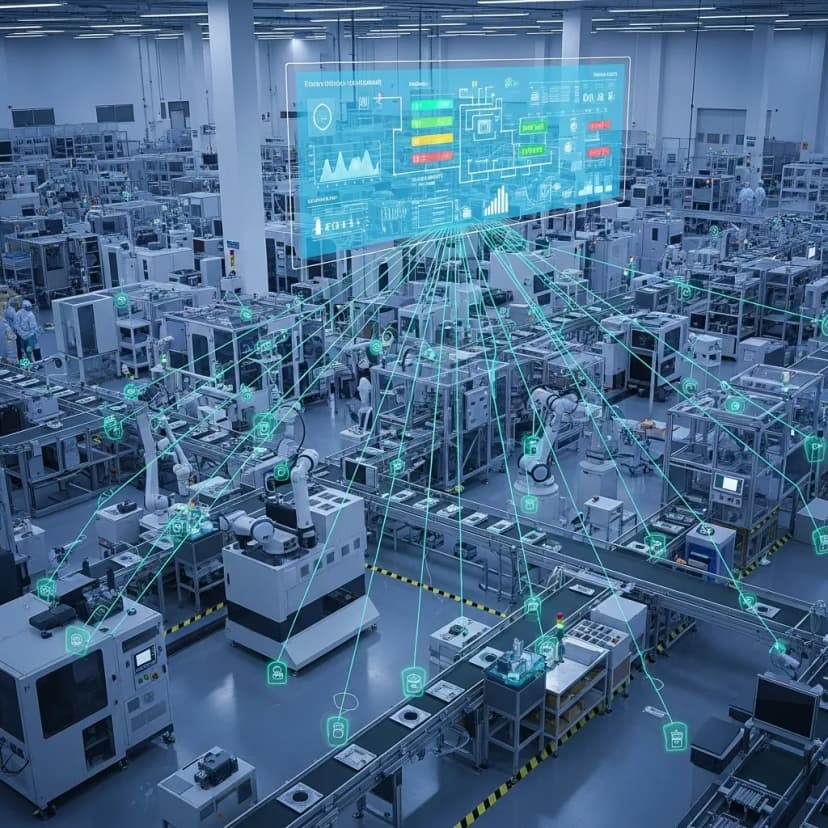

Ombrulla delivers AI- and IoT-powered solutions that enable automotive manufacturers to enhance quality, reduce downtime, and protect workers. From AI Visual Inspection to Agentic AI for decision-making, our platforms future-proof your operations in the competitive automotive industry.

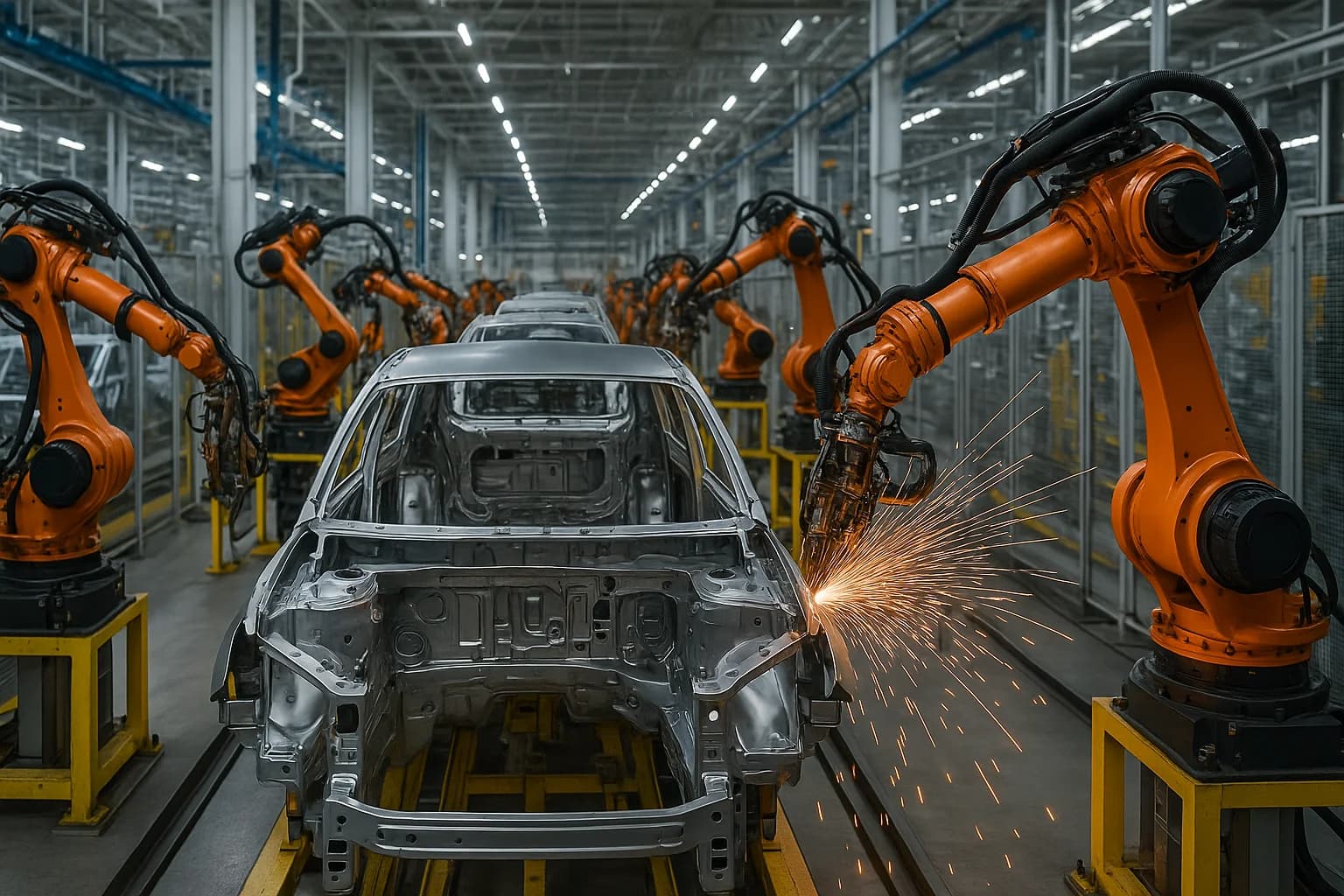

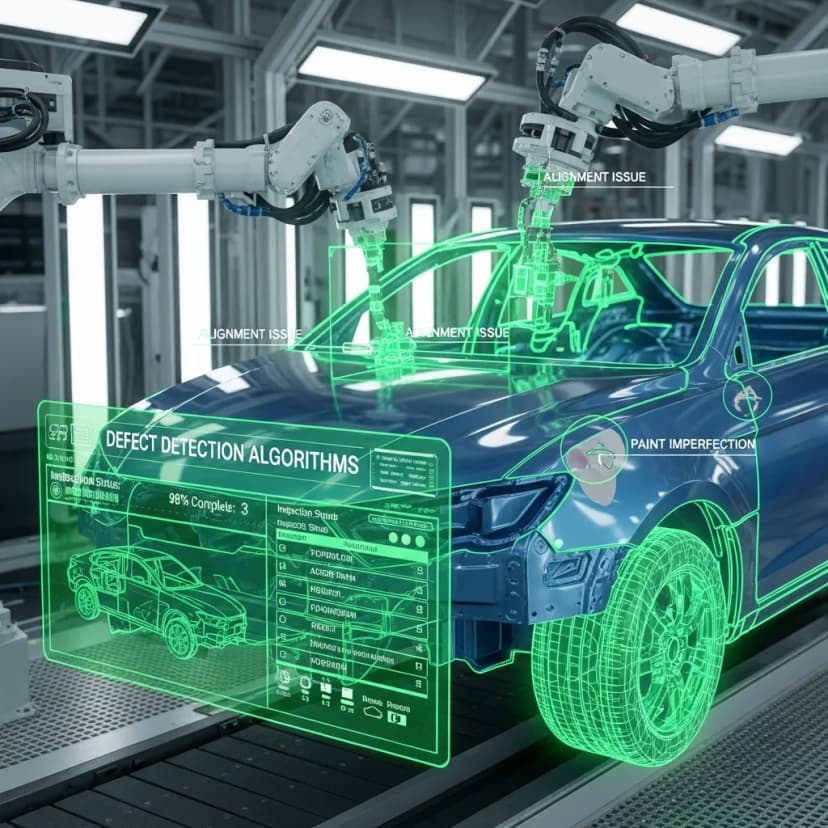

Automotive manufacturing demands precision at every stage. Manual quality inspections are time-consuming, inconsistent, and prone to human error.

AI-powered cameras and sensors inspect vehicle parts on assembly lines in real time.

Algorithms identify paint imperfections, alignment issues, and component defects instantly.

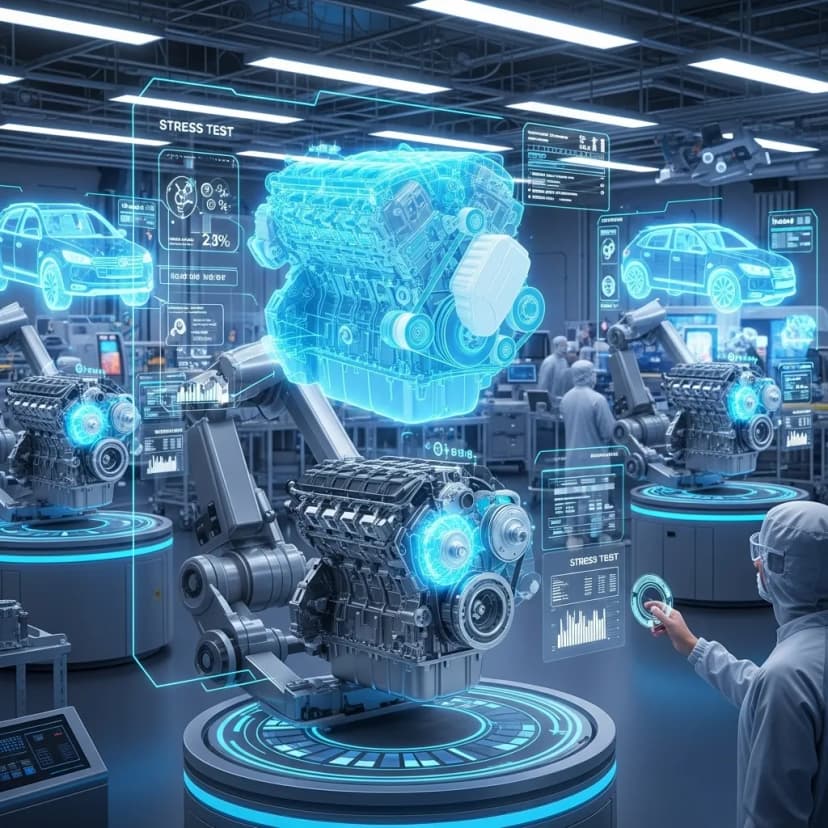

Virtual replicas of vehicles and machinery allow predictive testing and quality assurance.

Reduces defects and recalls by ensuring precision manufacturing.

Streamlines inspection processes and minimizes rework delays.

Fewer product failures mean lower after-sales service expenses.

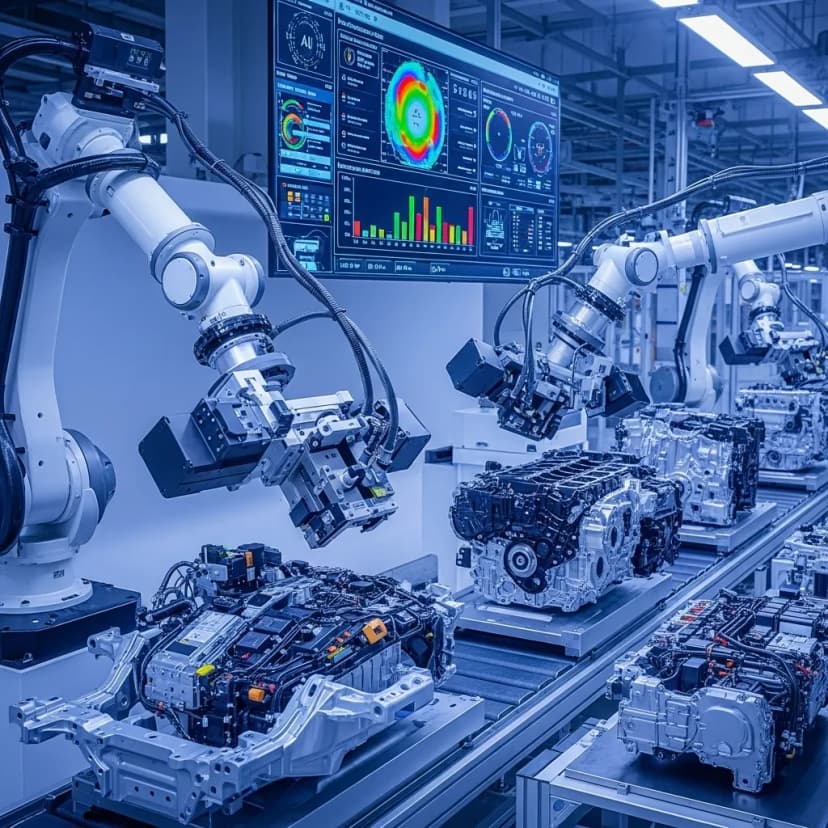

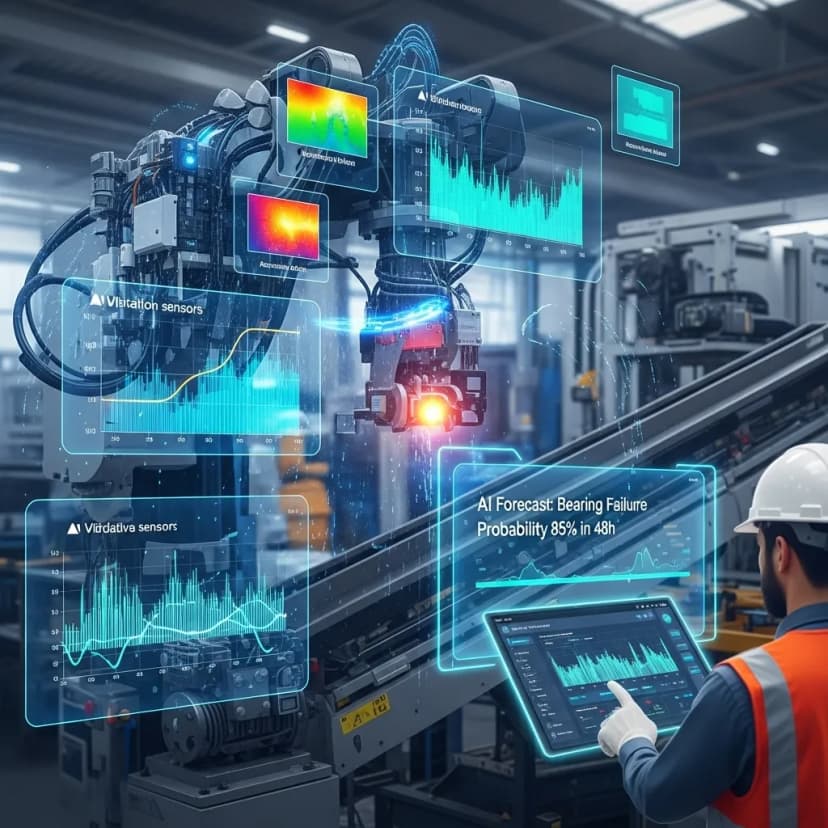

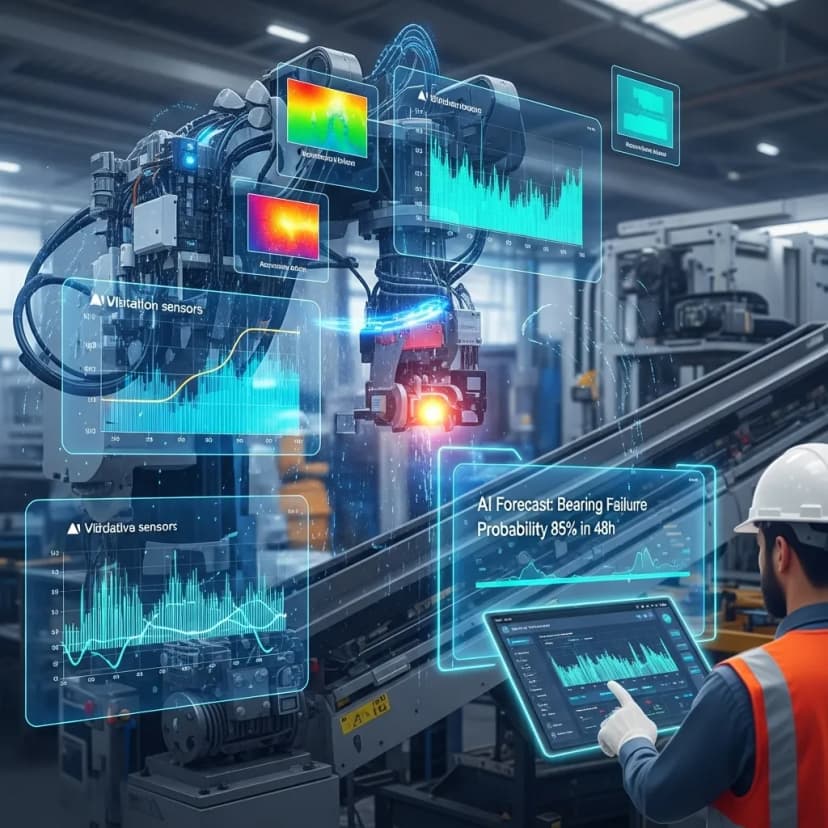

Automotive manufacturing relies on complex machinery assembly robots, conveyor belts, and production equipment that must operate continuously. Unexpected equipment failures disrupt production schedules and lead to costly downtime.

Sensors track performance of assembly robots, conveyor belts, and production equipment.

AI forecasts breakdowns before they disrupt production.

Local processing ensures instant alerts without relying on cloud latency.

Keeps assembly lines running continuously without unplanned stoppages.

Optimized maintenance schedules extend the lifespan of costly robotics.

Cuts repair and maintenance budgets while boosting throughput.

Automotive manufacturing plants are busy environments with heavy machinery, moving vehicles, and multiple hazards. Traditional safety measures often react too late to prevent accidents.

IoT-enabled helmets and badges track workforce safety and movements on the shop floor.

AI identifies hazardous zones and alerts workers in real time.

Wearables monitor vitals to prevent fatigue-related accidents.

Enhances worker safety across busy automotive plants.

Supports OSHA and ISO safety requirements with digital logs.

Boosts employee confidence in workplace safety measures.

Automotive manufacturing generates massive amounts of data from quality inspections, equipment sensors, and workforce tracking. Manual decision-making can't keep pace with the speed required for optimal production efficiency.

Aggregates inspection, equipment, and workforce data into a central intelligence hub.

Suggests corrective actions like adjusting production speed, reassigning workers, or scheduling maintenance.

Executes pre-approved decisions automatically while maintaining audit-ready records.

Eliminates delays in addressing production or safety issues.

AI-driven insights minimize risks of defects and accidents.

Improves efficiency, safety, and product quality in a highly competitive market.

See how Ombrulla’s AI and IoT solutions can elevate quality, maximize uptime, and enhance safety in your automotive manufacturing environment.

Tell us about your challenge - we’re here to help.