IoT Real-Time Monitoring for Always-On Operations

Real-time IoT tracking consolidates the view from your assets and sensors, see and mitigate issues before they cause downtime and respond without delay for all your locations.

Real-time IoT tracking consolidates the view from your assets and sensors, see and mitigate issues before they cause downtime and respond without delay for all your locations.

Manual readings, periodic inspections, and disconnected tools can’t keep pace with continuous production. The most expensive problems are usually the ones you notice too late: a bearing that slowly overheats, a pressure trend that drifts out of tolerance, a utility spike that keeps repeating every night shift.

Real-time monitoring changes the game by continuously collecting and analysing live data across assets, utilities, and the environment, so small anomalies don’t become failures, safety incidents, or shutdowns.

Catching early warning signals (vibration/temperature/current) and fixing issues before failure.

Shifting from reactive call-outs to planned, condition-based work orders.

Identifying peak demand spikes, leaks (compressed air/steam), and off-hours waste in real time.

Pinpointing when and where anomalies start, so teams troubleshoot with evidence instead of guesswork.

Those features that are the difference between a Pilot that may look good and an actual, lasting Rollout we consider crucial and are the main focus when evaluating a solution.

Onboard sensors, PLCs, meters, gateways (MQTT, Modbus, OPC-UA, REST, LoRaWAN), normalizing to a common model.

Real-time views with drill-down by site, line, asset, or parameter.

Detect subtle deviations and predict failures earlier than basic alarms.

Threshold/trend/time-in-state rules that trigger targeted alerts and actions.

Edge gateways for low latency and offline resilience; secure cloud/on-prem options with access controls.

Store and query large volumes of sensor history without performance drops.

Data stays tied to assets, lines, and processes so insights are actionable.

Connect to APM/CMMS/EAM, ERP/MES/SCADA, and BI tools so data flows into daily work.

Go from reactive fixes to predicting and optimizing services.

Connect to current devices, PLCs, and historians without vendor lock-in.

Designed for harsh environments and multi-site rollouts, with encryption, and IT/OT-aligned governance.

Templates, use cases, and deployment patterns from real implementations.

Real-time monitoring is different by sector, but the value proposition remains clear: avoid failures, prevent waste and stay safe.

Rotating equipment, pipelines, tanks, utilities to avoid failures, leaks or energy losses.

Machines + utilities + surroundings for OEE and quality to the maximum.

Discrete manufacture: robots, conveyors, presses, paint lines for early defect finding and cycle-time analysis.

Pumps, motors, transformers essential for preventing outages and safely managing loads.

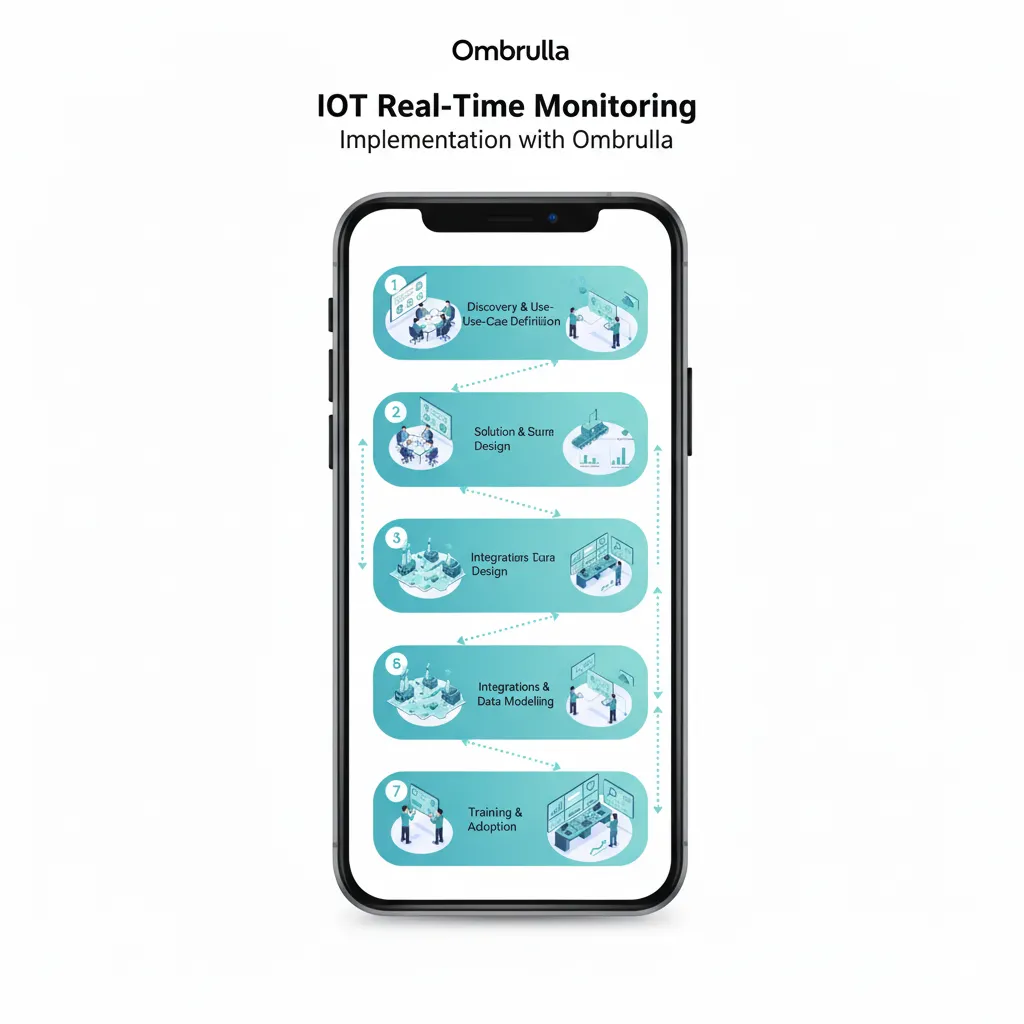

We help you turn your ideas into value using a struct. Oil and gas/energy: spinning machinery, pipes, tanks, and utilities to keep things from breaking down, leaking, or losing energy. red, low-risk trip:

A solid deployment extends beyond machines. It also enhances how teams collaborate to perform work:

When people feel safe, and supported, it all goes better. Real-time IoT monitoring enables you to see risk early, respond quickly and keep teams confident on the floor.

Real-time monitoring of Industrial IoT is viewing what your machines, utilities, or sites are doing now, with the current live data coming from sensors, meters, PLCs and gateways. Instead of waiting for a shift report or breakdown, you receive real-time visibility into asset health, performance, energy use and safety signals so you can act early.

Consider IoT monitoring to be the “eyes and ears” and APM as the “decision system.” Monitoring is when you have a tracking what happened live (temperature rising, vibration change and pressure gets stuck). APM tells you what to do next: what’s going to fail, how you can stop it from doing so, and what maintenance work should be scheduled. Solutions like Ombrulla can bring things together and provide oversight, PETRAN-style APM workflows to turn that data into maintenance and reliability outcomes.

It solves the mundane and daily ones: Unplanned downtime that costs in production goals, "Failed us equipment" we didn’t see coming, Energy losses that keep appearing on utility statements, Risk of non-compliance and security by missing limits, Too many siloed systems, and too few connections.

Because it provides you with more information earlier than operators can see right now. Most motor failures announce themselves in advance of the crash: current starts happening, heat rises, vibration moves or run cycles shift. Real-time monitoring snags those trends, sounds the alarm, and enables Predictive maintenance to respond in time to prevent it from becoming a shutdown.

Begin where failure has the greatest sting: Bottleneck machines, Equipment in rotation (Motors, Pumps, Fans, Compressors), Utilities (pressured air, cooling system, broilers, manipulate), High-cost or safety-critical assets. A smart first wave is usually 10-30 or so units, selected for most efficient maintenance/production, not just “anything that’s got sensors.”

Many plants start with the alarms that capture most of their common failure modes: Vibration (particularly for bearings and rotating machinery), Temperature (bearings, windings, surfaces, ambient), Pressure and flow (pumps, compressors, process stability), Electrical (amperage, voltage, wattage, power factor), Run-time, starts/stops, speed, load. You don’t need every sensor in all places everywhere. You want the right signals on the failure modes that matter.

SCADA is great at control and local supervision within OT networks. With that, you’re generally better off monitoring one way vs. the other. IoT monitoring is often best for: Visibility across multiple sites (single view of all locations), Long-term trending and analytics, Correlating information among different systems (assets + utilities + environment), Socialising dashboards to Ops, Maint and Mgt, Integrating with APM/CMMS tools. SCADA is retained by a lot of teams as their controller and monitors at lower tiers for enterprise visibility and decision making.

It can also involve processing data near the machines — at a gateway or local server, instead of sending it to the cloud right away. Teams use edge because: Alerts need to happen fast, At remote sites the connectivity can be patchy, Vibration high-frequency data perhaps? So basically on-prem or hybrid Deployments are required for some sites. Typically you would have edge (for local collection and first alarms) followed by central systems for reporting and APM.

In the wild cards in real life, you generally find a combination of brand new and older. Common protocols include: OPC-UA (modern industrial interoperability), Modbus (legacy equipment and meters), MQTT (IoT messaging), REST APIs (modern integrations), LoRaWAN (long-range for the large area networks). What we want to enable here is not “supports all the things” but “integrated and normalized data in a useful asset model”.

Alerts usually trigger from: Thresholds (temp > X), Trend/Rate Change (vibration rate too quick), Time-in-state rules (idle too long, running too long), High temp and high current Multi-signal logic, Anomaly detection (the above behavior pattern does not resemble normal usage). To prevent alert exhaustion, good teams queue alerts by asset and mode of operation at scale (add persistence rules [must persist N minutes], review ‘noisy’ alerts monthly).

Detection with computer vision AI visual inspection is training the system to recognize “normal” for a machine, part or process — and look for those additional pieces (as well as your specific defect type in some case) before it can be referred to as a defect or an alarm goes off. In the field, the camera serves as a persistent IoT sensor. It constantly takes pictures or video, feeding them to AI models that can detect the earliest warning signs — the first traces of corrosion, small wetness stains from a leak, slight surface deformation on gaskets and fittings indicating stress or wear and tear, misalignment, unexpected deposits, or changes in colour due to overheating.

Yes, and usually more quickly than teams anticipate. With real-time energy monitoring, you’ll be able to catch: The use of energy at off hours that no one individual is responsible for, Peak demand spikes, Leakage of compressed air and unsteady pressure, Underloaded equipment running unnecessarily, Equipment life reduction due to power quality problems. It also provides you with the trend data required for audits, as well as operational sustainability reporting.

For safety-critical applications, monitoring might be used to log the following: Gas detection and hazardous thresholds, Temperature/pressure limits in sensitive processes, Atmospheric conditions such as humidity, dust or emission, Event logs and history of the alarms for auditing purposes. It’s not about more alarms. It’s about less missing of events and better traceability and workplace safety when you do have evidence.

When Condition Monitoring is combined with CMMS/EAM: A verified alarm can result in a work request or work order, The work order can contain proof (trend charts, event time, sensor snapshots), History is fed back into the reliability analysis. This closes the loop so dashboards are used to take action, not just “interesting data.”

In the literature, most successful implementation processes in Ombrulla style monitoring occur in phases, including: Pilot Phase (2–6 weeks): In this phase, priority assets are connected, dashboards are constructed, and alerts are fine-tuned. Site Implementation Phase (1–3 months): In this phase, implementation is expanded to cover other sites, use case templates are standardized, and maintenance workflows are interconnected. Scaling up (3–12+ months): In this final phase, the implementation is replicated in other sites and production lines, ensuring the alignment of governance and cybersecurity policies. The rate at which these phases can be executed is determined by the network approvals, sensor availability, and integration scope.

A good dashboard is role-based: For operators: current status, top alarms, bottlenecks, line performance. For maintenance: asset health, trends, anomalies, time to failure signals. For reliability/management: downtime drivers, OEE, energy KPIs, top recurring issues. One dashboard cannot serve people well. The best setups have a unified and unique shared source of truth.

Cost can vary, but mostly includes: Number of assets/tags, data frequency; Edge hardware needs (gateways, industrial PCs); Integrations (SCADA/historian/CMMS/APM); Deployment model (cloud, on-prem, hybrid); Support and governance needs. A useful way to budget is "per site" or "per asset class" with all cost accounted for, including connectivity, sensors and change management, not just the software.

Typical high-value use cases include: Predictive Maintenance for CNC Machines; Predictive Maintenance for Transformers; Performances Prediction Of Employees Based On Skill Matrices; Predictive Maintenance of Compressors and Generators; Oil & Gas Pump and Compressor Failure Prediction.

PETRAN-style APM helps you move from “we saw an issue” to “we prevented the failure.” That means: Asset criticality and risk-based prioritization, Failure mode tracking and reliability analytics, Work order alignment and performance reporting, A structured path from monitoring signals to maintenance planning. In short: monitoring shows the symptoms; APM helps you treat the cause and prevent repeats.

Gauge what is happening in your business in real time. Our IoT platform monitors the health of your assets, energy use, environmental and safety conditions and helps identify and mitigate risks earlier, reducing downtimes and addressing minor problems before they develop into expensive issues.

Tell us about your challenge - we’re here to help.