In production environments, employee performance and machine performance are tightly linked, but they are typically managed in separate silos. Supervisors may see output and downtime at the line level, while operator assessments rely on periodic observations and lagging KPIs. This makes it difficult to distinguish process or equipment issues from operator-driven variability, and delays targeted training and optimal workforce deployment.

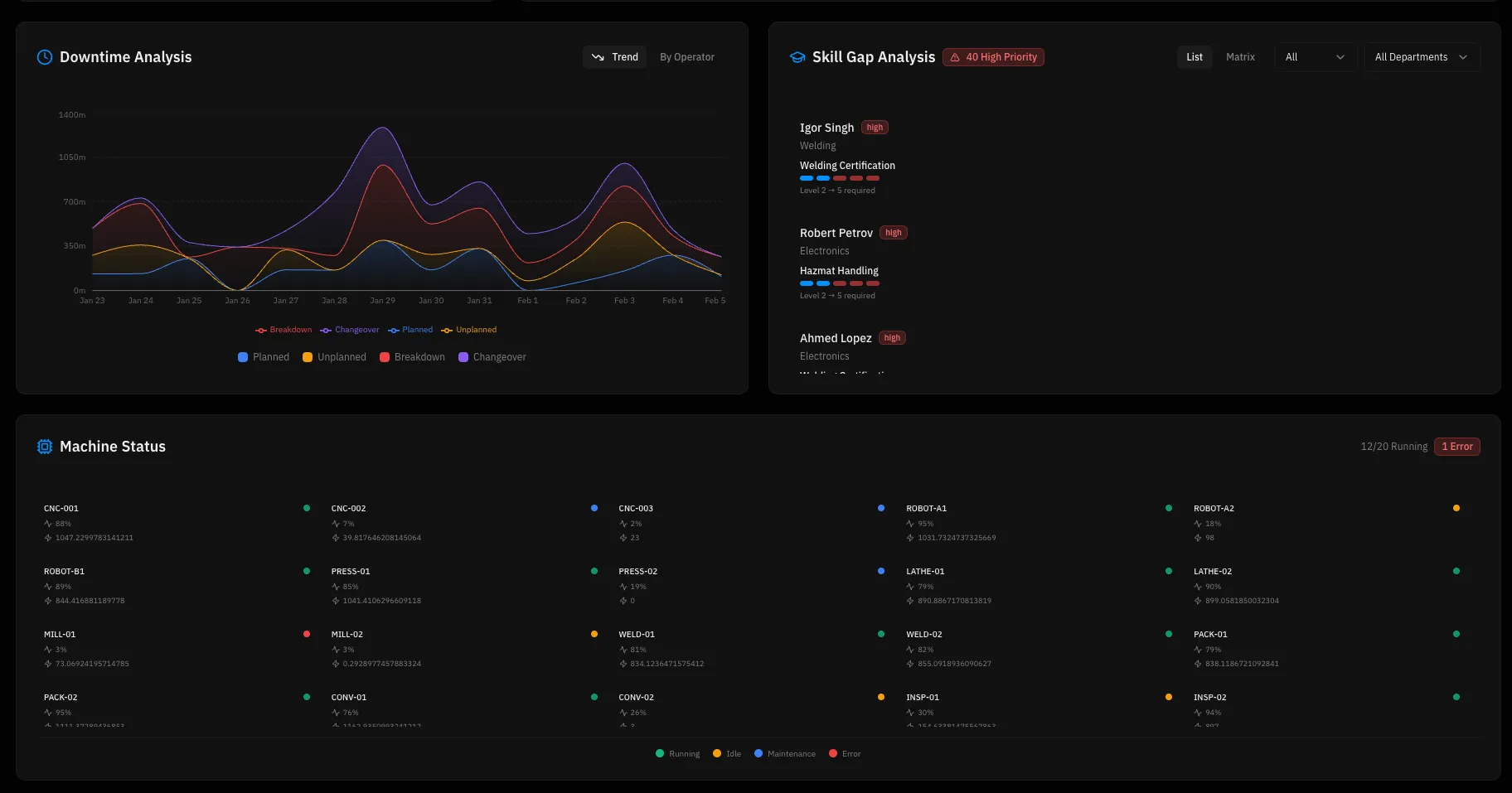

This use case applies AI to correlate machine performance signals (output, downtime, micro-stops, alarms, error codes, scrap) with operator attribution (station assignment, HMI login, work-order execution, shift rosters) to generate explainable insights and recommendations for training, staffing, and operational standardization.

The system ingests data from multiple sources to build a complete picture:

Cycle time, throughput, downtime reason codes, alarms, micro-stops, energy, sensor thresholds.

Defect types, scrap rate, rework frequency, first-pass yield, process deviations.

Operator attribution, station coverage, shift handovers, response times, crew composition.

Product variant, routing step, work orders, maintenance history, MTBF/MTTR context.

An AI-driven system is implemented to improve employee performance through:

Integrating real-time and historical machine KPIs with operator attribution data to build a unified event timeline per station and shift.

Analyzing output, downtime patterns, alarm frequency, cycle-time drift, and quality outcomes by product context.

Correlating machine behavior with operator actions (setup discipline, response time) while controlling for product mix and machine condition.

Predicting expected throughput, quality, and downtime risk for operator-machine pairings under current conditions.

Surfacing explainable drivers of underperformance, recommending targeted micro-training, and optimal staffing.

Industry Reference: Predictive maintenance for pumps and compressors is vital across process industries and manufacturing operations. AI monitoring detects degradation patterns before catastrophic failures impact production. This approach reduces maintenance costs by 20-30% while maximizing asset utilization and energy efficiency.

Organizations implementing operator-machine correlation analytics typically realize:

Reduction in machine idle time and micro-stops through faster diagnosis of operator-driven failure modes.

Higher throughput and steadier cycle times by assigning best-fit operators to constraint stations.

Lower scrap and rework by targeting training to the exact behaviors and process steps driving defects.

Focus interventions on high-impact gaps instead of broad retraining.

Illustrative outcome: An electronics assembly company used AI to identify station-specific skill gaps and coaching opportunities, improving operator efficiency and reducing machine idle time by 20%.

Tell us about your challenge - we’re here to help.