Ombrulla successfully transformed its Pre-Despatch Inspection (PDI) for industrial vehicles using an AI Visual Inspection system powered by 10 strategically placed cameras. The solution validates 78 inspection checkpoints in seconds - a process that previously required more than 30 minutes per vehicle - while improving consistency, auditability, and dispatch throughput.

Ombrulla successfully transformed its Pre-Despatch Inspection (PDI) for industrial vehicles using an AI Visual Inspection system powered by 10 strategically placed cameras. The solution validates 78 inspection checkpoints in seconds - a process that previously required more than 30 minutes per vehicle - while improving consistency, auditability, and dispatch throughput.

End-of-line Pre-Despatch Inspection (PDI) - the final quality gate before a vehicle leaves the facility.

Ombrulla's PDI relied on manual visual checks and checklist-based sign-off. The approach was dependable but constrained by cycle time and variability.

Manual PDI required more than 30 minutes per vehicle, creating a queue at dispatch.

Results varied by inspector experience, fatigue, and shift conditions.

Limited visual proof for audits, customer disputes, or internal root-cause analysis.

Volume growth required additional inspection labor rather than improving flow.

Late-stage correction cost: Defects discovered at PDI are more expensive to resolve than upstream fixes.

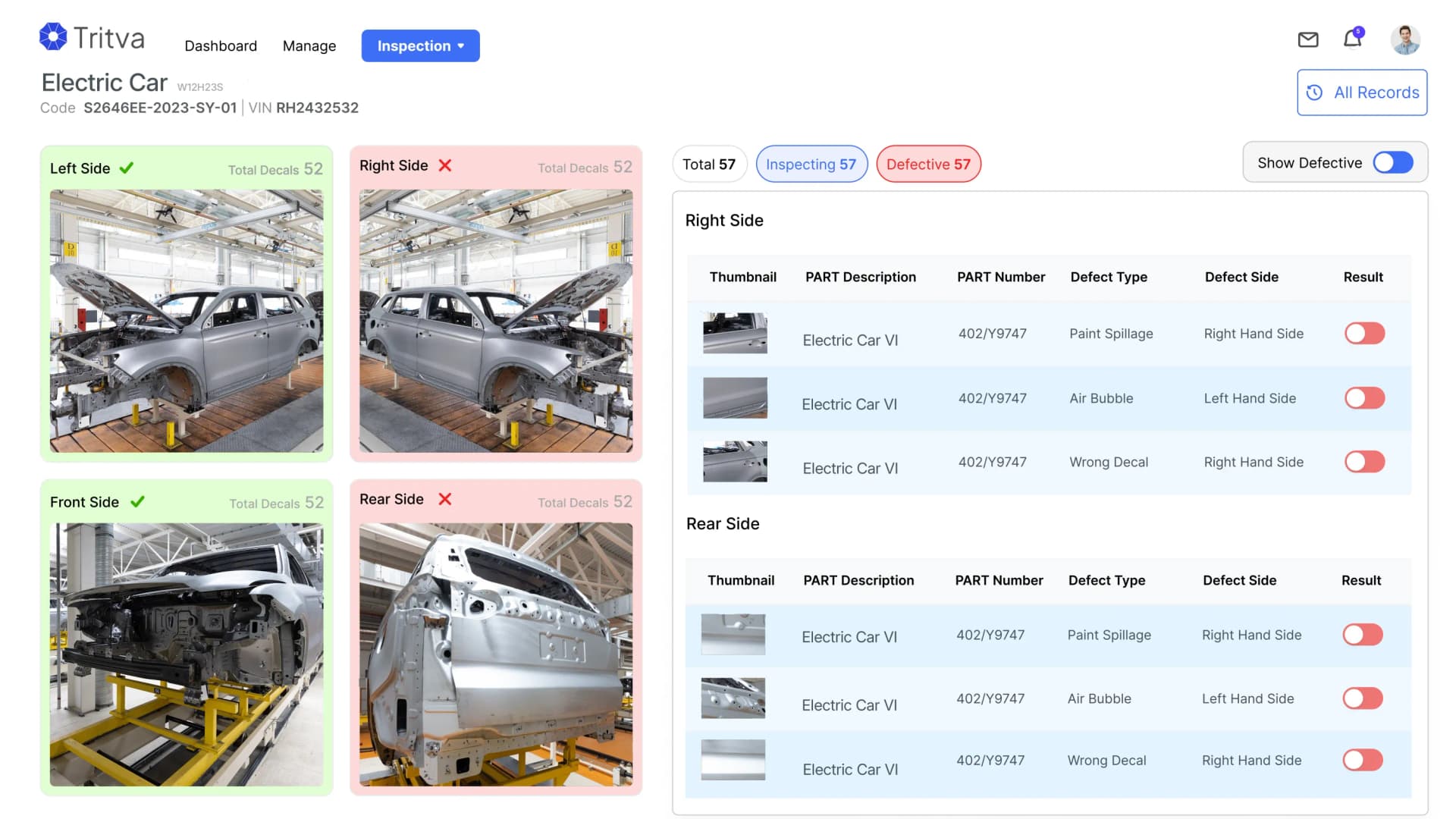

Ombrulla implemented an AI Visual Inspection solution for PDI using 10 cameras positioned at strategic locations around the inspection bay. With a one-click capture, the system ingests synchronized images and automatically evaluates 78 checkpoints in seconds.

What changed operationally:

10 cameras placed to maximise coverage across front, rear, side profiles, and cabin-area views to reduce blind spots.

Vehicle enters PDI bay, operator triggers capture, and system collects images from all 10 cameras simultaneously.

AI models evaluate 78 checkpoints in seconds (presence/absence, alignment, defects, labelling compliance).

Dashboard presents pass/fail per checkpoint, highlights areas of interest, and logs evidence against vehicle ID.

Inspectors focus on confirming exceptions, providing feedback, and supporting root-cause analysis.

Core performance gains from the implementation.

The 78 checkpoints are managed as a controlled checklist and can be summarized into leadership-friendly groups:

Lights, reflectors, mandatory markings, warning labels.

Panel alignment and surface anomalies visible at dispatch.

Presence of required parts, caps, guards, fasteners.

Decals, VIN/ID plates, serial label readability.

Dispatch readiness: visible damage risks, accessories, packaging conditions (where applicable).

Delivery phases used to reach production readiness:

Tell us about your challenge - we’re here to help.