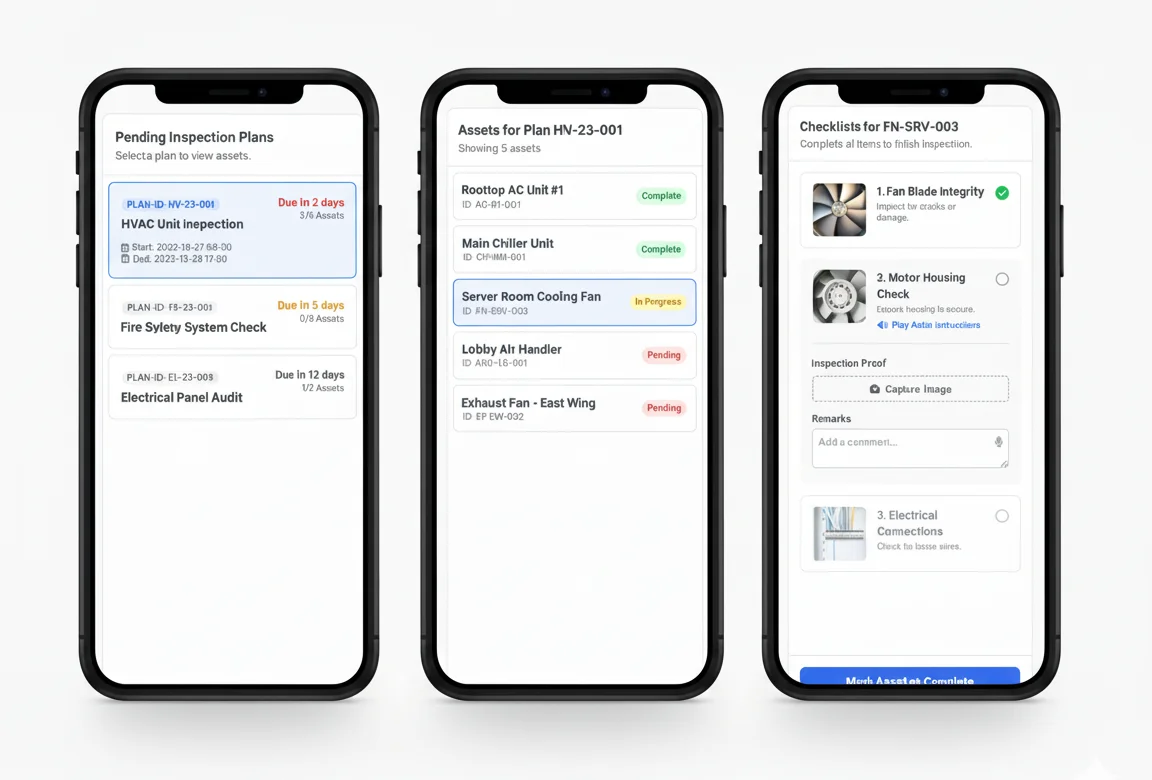

Ombrulla Mobile AI Inspection converts routine field rounds into consistent, decision-grade results. Inspection plans are pushed to the inspector mobile app, assets are identified by zone, and asset-specific checklists guide evidence capture. The system evaluates captured images and inspection data to surface defects, anomalies, and risks quickly while producing an audit-ready record by default.

Typical inspection scope across a large facility includes:

Pipelines, valves, pumps, compressors, tanks, rotating equipment, structural supports.

Switchgear, MCC panels, transformers, motors, control panels, gauges and indicators.

Signage, barriers, housekeeping, restricted-zone checks, permit-to-work evidence capture.

Subjective decisions and uneven documentation across inspectors and shifts.

Photos and notes are reviewed later, increasing exposure to downtime, failures, and incidents.

Images, checklists, and readings are stored in different systems, weakening traceability.

Long routes, hard-to-reach equipment, variable lighting, harsh environments.

Additional challenges include connectivity constraints where offline zones create gaps in timely reporting and follow-up.

Plan and push inspection routes and checklists to the inspector mobile app (by asset class, criticality, and zone).

Inspector identifies the asset using the zone system, opens the asset checklist, and captures required images and readings.

AI-assisted evaluation analyses captured evidence to surface defects and anomalies and validate readings where applicable.

Results return immediately with severity and recommended actions, triggering alerts and maintenance follow-ups.

All evidence and outcomes are stored as an audit-ready record for compliance, analytics, and continuous improvement.

Tell us about your challenge - we’re here to help.