Introduction: A Practical Guide to AI Defect Detection

Factory work rarely gives anyone time to slow down. Products move past in seconds, and workers do their best to keep up, but no one can stare at the same thing for hours without missing a detail here and there. A tiny scratch, a small dent those things slip by when the pace is constant. That everyday challenge is exactly why many factories have started using AI defect detection. It’s not some flashy high-tech replacement for people. It’s more like an extra pair of steady eyes that doesn’t get tired, helping catch issues early so the work on the line stays smooth.

The concept sounds technical, but the experience feels pretty normal in practice. A camera keeps an eye on the line, and the system quietly watches along with it. When something doesn’t look the way it should, it doesn’t panic it simply points it out, almost the way a co-worker might tap your shoulder and say, “Hey, take a second look at this.” It’s not trying to replace anyone or make big decisions. It just fills in the gaps during those moments when the line doesn’t stop and the human eye gets tired.

If you’re new to all of this, don’t worry about the science behind it. You don’t need to understand algorithms or code. The point is much simpler: it helps catch problems early so they don’t snowball later. This guide is meant to walk you through what the technology actually does and why manufacturers are finding it helpful without turning it into a technical lecture.

What Is AI Defect Detection in Manufacturing?

My initial reaction to hearing people discussing AI defect detection was another technology buzzword. However, having worked in the place where metal housings to the automotive sensors are produced, I realized why teams use it. Stand beside a fast conveyor for twenty minutes and your eyes simply stop catching the tiny flaws. I watched an inspector miss a hairline crack because the lighting shifted when a forklift passed. It wasn’t her fault the parts look the same, the pace is relentless, and humans get tired.

That’s where AI steps in. Not dramatically, but more like a quiet coworker who taps your shoulder and says, “Hey, check this one.” It picks up dents, scratches, or misaligned edges that people naturally overlook under pressure. It doesn’t replace anyone; it just fills the gaps that appear when real humans work in real manufacturing conditions.

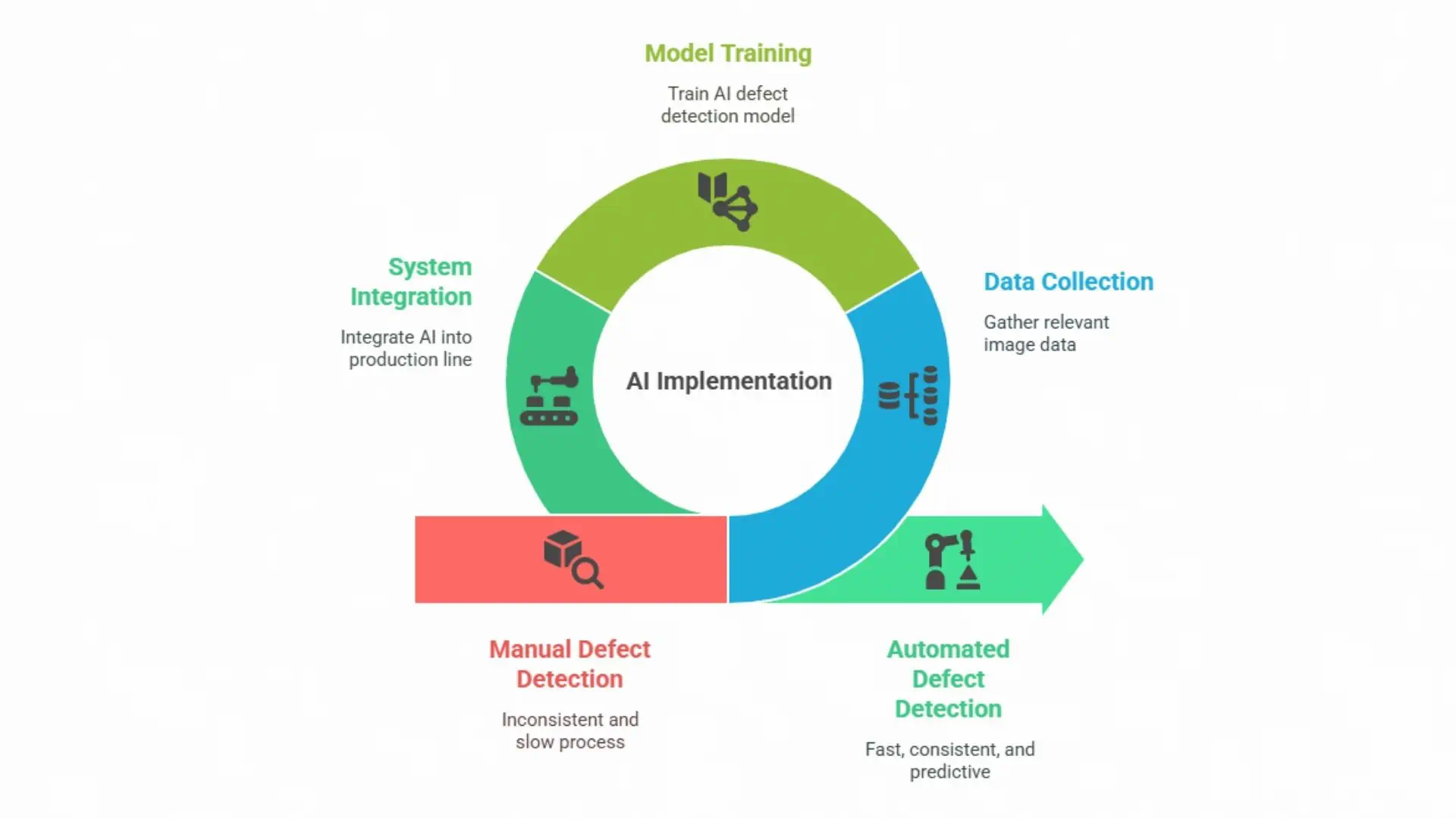

How AI Visual Inspection Works for Defect Detection (Step-by-Step)

This is where AI detecting defects comes in. In a busy production line, one has no time to pick up all the items on the line and carefully examine them. Each item passes a camera that captures a snap and the system provides it with a brief inspection- nearly like a person inspecting that everything is as it is. Whenever something appears out of context, AI-based visual inspection systems point it out so operators can take a second look. It is not aiming to replace anybody, it just pays attention to the minor details that are usually lost when things become hectic.

Image and Data Capture in AI-Based Defect Detection

•In most factories, the process starts with cameras placed wherever defects tend to show up. I’ve seen setups where a simple angle change doubled the detection accuracy. These images give the AI something real to study, and if the lighting or camera drifts even slightly, you feel it in the results.Preprocessing for AI Inspection Accuracy

•I’ve learned that the AI can only be as good as the images you feed it. Before it checks anything, the system does a quick cleanup adjusts the lighting, reduces random specks, and evens out the contrast. It’s not fancy work, but when this part is skipped or done in a rush, the whole AI visual inspection setup starts giving odd results. Good preprocessing doesn’t get much attention, yet it quietly decides how reliable the final defect detection will be.Training AI Models for Accurate Defect Detection

•Training isn’t glamorous. You feed the model thousands of examples good parts, bad parts, odd in-between cases. The AI slowly learns what “normal” looks like. I’ve watched teams debate over a single mislabeled defect because one mistake can nudge the model off track.Real-Time AI Analysis in Manufacturing

•Once deployed, the AI doesn’t hesitate. It checks every part the moment it appears on the line. In one plant I visited, the system flagged defects faster than a worker could blink. Real-time analysis is where AI defect detection actually proves its worth under pressure.Automated Alerts and Defect Reports

•When the AI spots something unusual, it fires off a quiet alert nothing dramatic, just a quick nudge so the operator can look closer. The reports help show patterns too. One factory discovered a loose fixture just from repeated alerts in the same corner of the product.Continuous Learning for Enhanced Quality Assurance

•AI systems don’t stay the same for long. Once they’ve seen a few weeks of parts roll down the line, they start adjusting their judgment almost like a new hire finally getting the hang of the job. In some plants, we update the model every Friday because even a small change in tooling throws off the earlier settings. This steady trickle of learning is what keeps defect detection from drifting as production shifts.

Who Should Use AI Defect Detection in Manufacturing?

AI defect detection isn’t just for giant factories with robots everywhere. The teams that benefit the most are the ones constantly fighting small, annoying quality issues that eat up time and budget. If your line runs fast, your inspectors keep flagging the same mistakes, or you’re dealing with customer returns that feel avoidable, this tech is worth looking at.

I’ve seen it help operations managers who juggle multiple lines, quality engineers who get pulled into root-cause meetings every other day, and even smaller shops that simply can’t afford scrap piling up. Anyone trying to hold a consistent standard in the middle of shifting materials, tight deadlines, or growing demand usually sees the value quickly.

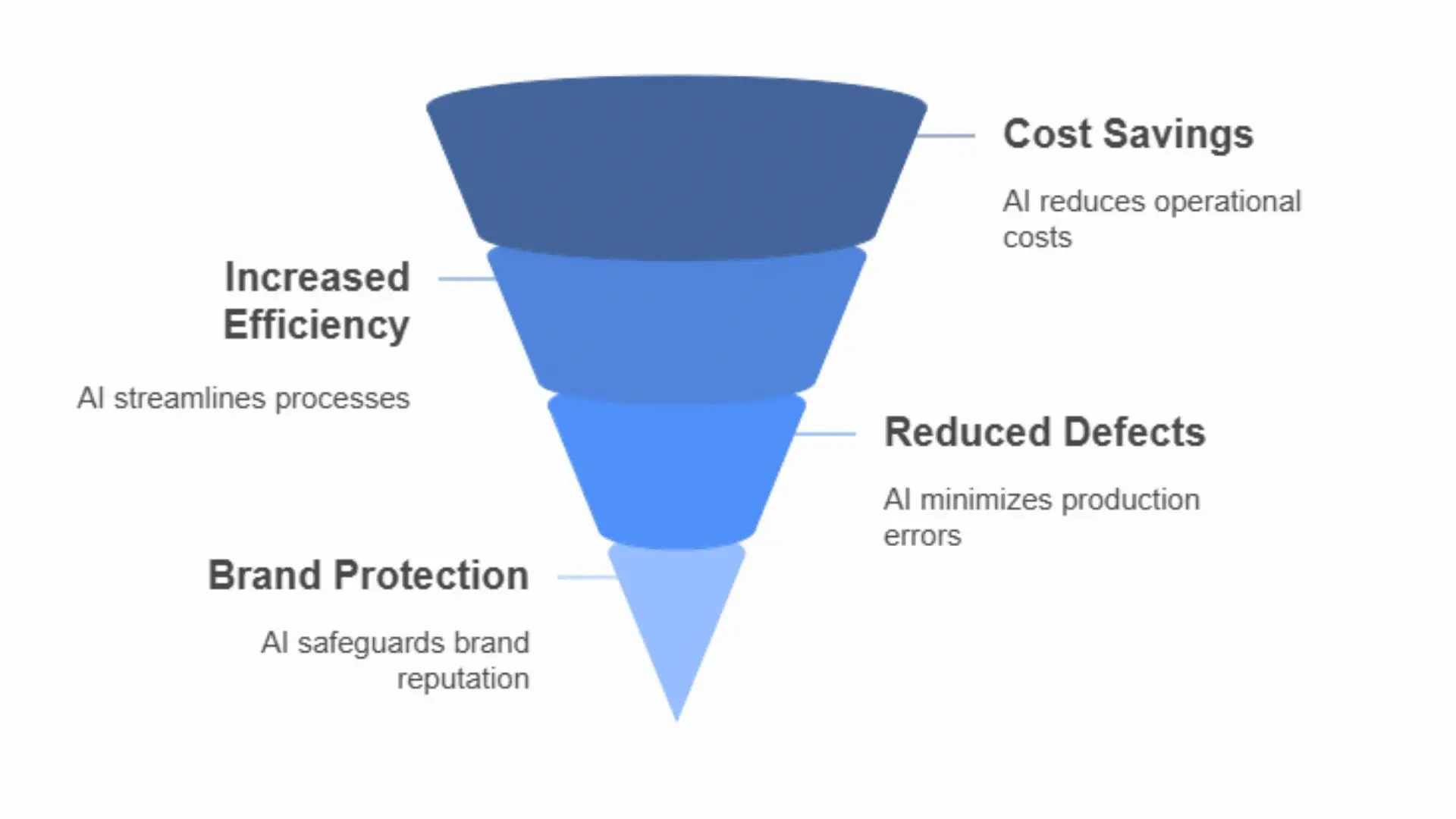

Why Senior Management Supports AI Defect Detection

For leadership, the appeal lies in consistency and data. AI delivers reliable metrics that help improve the entire production lifecycle, from minimizing scrap to maximizing throughput.

Real-World Use Cases of AI Defect Detection

Automotive: AI for Paint, Assembly, and Panel Defects

AI is used to detect paint inconsistencies, body panel defects, engine assembly issues, and component misalignments in real-time.

Electronics: AI for PCB and Micro Defects

High-speed cameras combined with AI detect soldering defects, PCB alignment issues, and microscopic flaws that human inspectors can easily miss.

Textiles: AI for Weaving and Dyeing Quality

AI identifies weaving defects, dye inconsistencies, and surface flaws in fabrics, ensuring batch consistency.

Food & Beverage: AI for Packaging and Product Inspection

AI systems inspect food items for shape, color, texture, and contamination, improving packaging and reducing recalls.

Key Features to Look for in an AI Defect Detection System

Not all AI defect detection systems are worth the investment. I’ve seen plants buy impressive demos that quietly failed on the shop floor within weeks. The real test isn’t how smart the AI sounds it’s how well it survives real production chaos.

Image Reliability Over Fancy Models

•First, image reliability matters more than fancy models. If the system can’t handle uneven lighting, dust on lenses, or slight camera shifts, it will flood teams with false alarms. One automotive supplier I worked with had to pause deployment because a single overhead light replacement changed defect accuracy overnight.Adaptability to Change

•Second, look for adaptability, not perfection on day one. Materials change. Tools wear down. A good system adjusts without needing a full retraining project every time something shifts. Teams that skip this regret it fast.Transparent Explainability

•Third, explainability is underrated. When the AI flags a defect, operators should instantly see why. If people don’t trust the output, they ignore it and then the system becomes shelfware.Workflow Integration

•Finally, check how easily it fits into existing workflows. The best AI defect detection system is the one your team actually uses every shift, not the one with the longest feature list.

How to Get Started with AI Defect Detection

Start on the Shop Floor

•Most companies overthink this step. You don’t start with AI models or huge datasets you start by standing on the shop floor. Watch where defects actually slip through today. In one electronics plant I worked with, 70% of quality issues came from just one inspection point everyone assumed was “fine.”Pick One Process

•Next, pick one process, not the whole factory. A single product, a single defect type, one camera. Teams that try to automate everything at once usually stall before anything goes live.Realistic Data Expectations

•Then comes data, but keep expectations realistic. Your first images will be messy bad lighting, odd angles, inconsistent parts. That’s normal. A good AI defect detection system improves with these imperfections; it shouldn’t require perfect conditions to function.Involve Operators Early

•Finally, involve operators early. If the people on the line don’t trust the system, they’ll ignore it. The fastest deployments I’ve seen treated AI as a helper, not a replacement and that mindset made all the difference. Teams that move fastest usually work with partners who understand real factory conditions, not just algorithms.

The Human Role in AI-Powered Defect Detection

Combining Human Expertise with AI Visual Inspection

AI may be intelligent, but the human role remains essential. Experts are needed to:

Training the system

•Engineers decide what counts as a real defect and label images based on actual production impact, not just visual differences.Handling edge cases

•When the AI flags something unusual like a harmless mark caused by tooling wear humans decide whether it’s a problem or noise.Adapting to change

•New materials, lighting shifts, or machine adjustments can confuse models. Operators help recalibrate the system so accuracy doesn’t drift.Final accountability

•AI can suggest, but people make the call. Quality teams remain responsible for release decisions, audits, and compliance.

In real manufacturing environments, AI defect detection doesn’t replace human expertise it relies on it. The best results come when machines handle repetition and people handle responsibility.

Why AI Defect Detection Is the Future of Manufacturing

Manufacturing teams are under pressure that didn’t exist ten years ago. Volumes are higher, tolerances are tighter, and customers notice even the smallest mistake. Relying only on manual checks just doesn’t hold up anymore. AI defect detection steps in because it can keep up when people physically can’t.

What makes it future-proof isn’t the technology buzz it’s reliability. The system watches every part, every shift, without slowing down or losing focus. When defects are caught early, scrap drops, recalls become rare, and teams spend less time firefighting. For leadership, this isn’t about replacing workers or chasing automation trends. It’s about protecting margins, keeping customers happy, and making sure quality doesn’t fall apart as production scales. Manufacturing teams are under pressure that didn’t exist ten years ago, and AI in manufacturing is becoming a practical way to keep quality steady at scale.

Frequently Asked Questions

Think of it like this: instead of someone standing there staring at products all day, a camera does the looking and a computer tells you, “Hey, something feels off with this one.” That’s pretty much it. Nothing fancy. Just a quicker way to spot mistakes before they turn into bigger problems.

Honestly, it’s mostly automatic. The camera snaps pictures as things move past, and the system checks them in the background. If something doesn’t look right, it taps you on the shoulder well, not literally, but you get the idea.

Yeah, surprisingly often. Humans drift after a few hours, even the best ones. The system doesn’t. It just keeps going, same pace, same attention, whether it’s morning or almost midnight.

A bit of both. It catches the small stuff right away, but when you look back at the patterns, you can usually figure out where the real problem started. That part ends up saving more time than people expect.

Because it doesn’t have “good days” or “bad days.” It just follows the same logic wherever you put it. That’s why companies like using the same setup in different locations.

Yeah, indirectly. If you find problems earlier, you throw away less material. Less rework too. The line runs cleaner, which is nice for both budgets and the planet.

Every line has its own quirks. Lighting changes. Machines vibrate differently. You might have shadows in one corner. The system needs a bit of time to adjust to each place. Once it settles, it’s fine.

The first setup does cost something. Cameras, software, the usual. But the money you save from fewer mistakes tends to come back faster than most people expect. That’s why companies stick with it.

They just make it easier to reach weird spots high shelves, tight corners, places people shouldn’t squeeze into. They take the pictures, and the system checks them like everything else.

No. It helps them, but it doesn’t replace them. Someone still needs to make the call on unusual cases, fix problems at the source, and decide what happens next. The system handles the tiring part; people handle the thinking part.