Tell us about your challenge - we’re here to help.

Quality checks sound simple when you think about them just look at a product and make sure nothing is wrong. But in real factories, things don’t move slowly. Products come down the line nonstop, and expecting people to catch every tiny scratch or misalignment is harder than it sounds. Anyone would get tired. Anyone would miss things. So many companies have turned to something called AI visual inspection.

It may sound complex, but it’s easy to understand: a camera takes pictures of the product and software analyzes them to spot defects or anything unusual. It’s similar to having eyes that don’t get tired or lose focus. What makes this useful is not that it replaces people but that it helps them. When thousands of items pass by every hour, having a system that points out the “hey, something looks off here” moments can save a lot of trouble later on.

A small defect caught early is much better than an expensive recall or a rejected batch. If you’re completely new to this topic, don’t worry. You don’t need to know how AI works internally. This guide gives you a simple idea about how this technology works, why companies use it, and how it plays a role in quality control. Think of it as a friendly introduction, not a technical manual.

Don’t worry if you have never heard about AI visual inspection before. It sounds technical, but the main idea is really easy to understand. Imagine someone checking a product on a table. They pick it up and check it from a few angles, maybe check for bumps or scratches. That's really all inspection is.

Imagine having to do that again and again. No one can keep up with that. People get tired, lose focus, and small mistakes start to happen. This is pretty much why companies started using cameras and software to help out.

AI visual inspection is basically a camera taking pictures of whatever is being made, and a program trying to notice when something looks “off.” Not in a scifi way more like comparing today’s item with what a normal, good one should look like. If something seems odd, the system points it out. AI visual inspection is basically a way of letting a camera and some software help check products for mistakes when they move too fast for people to catch everything.

The system just looks at images and tries to notice when something doesn’t look quite right like a scratch, a wrong shape, or something missing. It’s not doing anything magical or replacing people; it just points out things that might need a second look, especially when production is busy and human eyes get tired. AI Visual Inspection solutions are simply another tool in the quality check toolbox. A helpful one, especially when the pace is too fast for human eyes to keep up.

AI visual inspection is used, in large part, because things move so quickly that no human can ever thoroughly check everything. Even careful inspectors, gazing intently by the hundreds every minute, eventually miss small scratches, loose parts or tiny defects. The AI simply aids in catching those earlier so there’s not as much of a backlog later. Consistency is another reason companies rely on it people get tired or distracted, computers don’t. It maintains its focus all day long. For most industries, it is just a sensible way to prevent expensive errors and keep the production line humming without placing under pressure on workers manufacturing quality control challenges.

AI improves quality checks by identifying small issues that humans often miss when things are moving quickly. It remains almost bizarrely focused all day, delivering better and more consistent results. It enables early error detection, eliminating rework and potential bigger mistakes, which in turn contributes to making the inspection process generally more efficient for workers and easier to manage.

If you try to imagine how this whole thing works, it’s honestly not complicated. The camera just snaps a picture kind of like someone taking a quick look without stopping anything. Then the software stares at that picture and tries to make sense of it.

It’s basically asking itself, “Hmm, does this look normal?” Most of the time it does. But if something feels off a weird line, a small dent, or a shape that doesn’t match it nudges the system to say, “Hey, check this one.”

Nothing dramatic. It’s more like a quiet tap than a loud alarm. And the more it looks, the better it gets. It starts to notice tiny things you wouldn’t even think about not because it’s smart in a human way, but because it’s seen so many examples that it gets good at spotting the odd one out.

This entire thing really begins with a camera. It simply takes a picture as the product goes by no frills. It’s like taking a snapshot while walking. It’s right sometimes, wrong other times, but it’s something for the system to chew on.

After that image hits the system, the software goes checking through the image. It's not doing anything crazy, just looking for the common spots and making sure what it sees there is what it expects to see. Some days it catches tiny ones that I might not even see if I looked directly at them.

If something looks off a dent, perhaps, or a corner that doesn’t match the others the system responds. It isn’t fancy about its calculation; it just notices the way you’d look at something, think “hmm, that’s weird,” and move on.

If the system is uncertain of what it saw, it sends a small alert. Not a giant alarm, but rather a nudge: “Hey, perhaps take a look at this one before it gets out of control.” Mostly, it will help prevent the backlog from piling up later.

The system, after thousands of images, does slowly improve. It remembers patterns without anyone having to teach it every rule. Kind of the way you learn to spot flaws faster after you’ve been doing a job for, oh, 40 years or so which is experience accrued in the background.

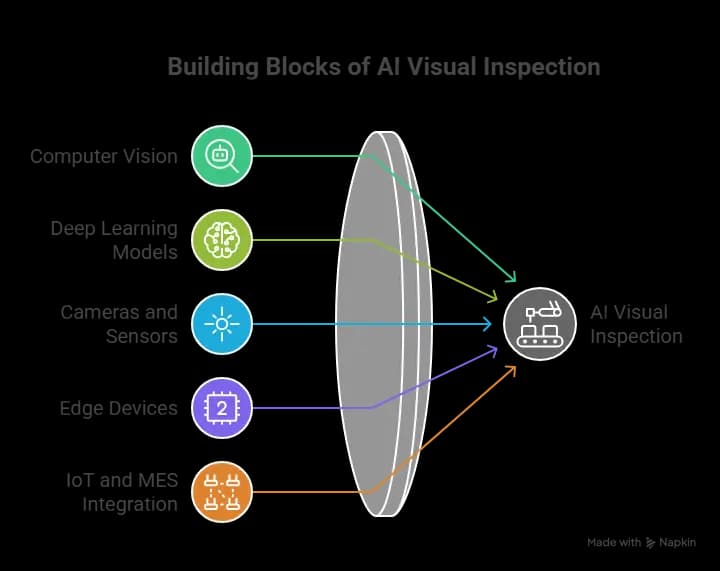

When people hear “AI visual inspection,” they often imagine something complicated running in the background. In reality, it’s built from a handful of tools that work together in a pretty simple way. None of them are magical they just do their own part and make the whole process smoother.

We usually say this is the ‘eye’ of the system. The software has to understand what it is analyzing. Even the smallest of details like the edges, shapes, and textures need to be processed, and things that those of to do and from to work and look at the pictures like a grind the software needs to be programmed to see and analyze. It's certainly not perfect, but it gives the software something to use.

Consider this the section that acquires knowledge through instances. Present it with an array of quality items and some inferior products, and it begins to discern the variation. It assimilates knowledge the same way humans do, gradually at the beginning and then more rapidly after an adequate quantity of patterns has been reviewed.

The technology doesn’t work without clear images. Depending on the industry, factories use normal cameras, 3D scanners, or even infrared sensors. The idea is simple: capture what’s happening on the line so the system has something real to evaluate.

Instead of sending every image to the cloud, some factories process them right beside the production line. It keeps things quick no waiting, no delays. When you’re dealing with thousands of items an hour, those seconds matter.

This is the part that helps everything talk to each other. If something looks wrong, the system can notify a machine, slow the line, or simply flag a product. It keeps the inspection from being just “interesting information” and turns it into something useful.

Most people imagine inspection as someone standing by a line, quickly looking over each item. That works when things move slowly, but modern factories don’t work at that pace anymore. Products come through too fast, and expecting anyone to stay sharp all day isn’t realistic. This is where AI really helps not by replacing people, but by backing them up.

AI tends to notice the tiny things that slip past human eyes, especially after hours of repetitive work. It doesn’t guess or rush; it just reacts to differences it sees in the image.

Machines don’t pause to think. As soon as an image appears, the system checks it. That speed matters when thousands of items pass through in a single shift.

People’s focus changes throughout the day tired mornings, busy afternoons, distractions. AI doesn’t have “good days” or “bad days.” It does the same type of check every single time.

Some inspections involve heat, chemicals, or awkward positions. Letting a camera handle those parts keeps workers out of risky spots, which is a win for everyone.

AI doesn’t need breaks, coffee, or fresh eyes. If the production line keeps running, the system keeps checking without slowing down.

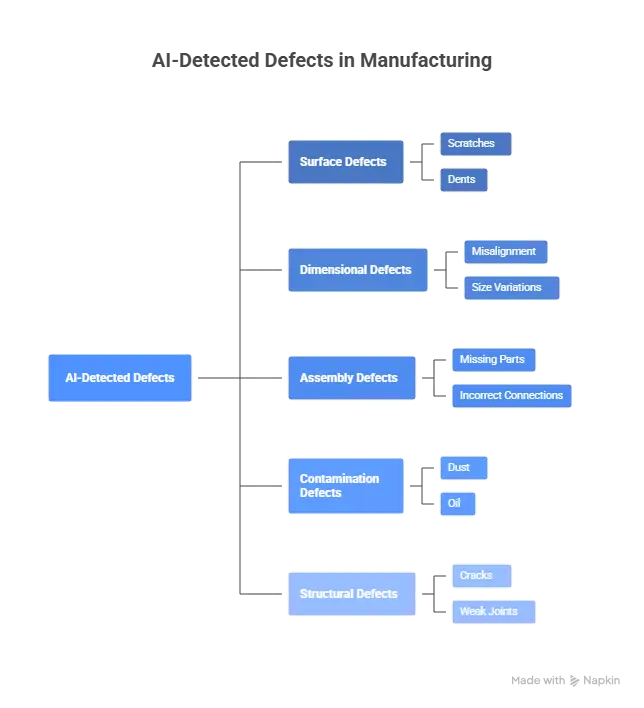

When people hear “defects,” they usually imagine one big problem, but in factories it’s rarely that simple. Things go wrong in different ways, and AI just helps notice them faster. Here’s a quick idea of what it usually catches nothing too technical.

AI visual inspection shows up in more places than people realize. Once you notice how fast things move in modern factories, it makes sense why companies lean on it. Here’s a simple, beginner friendly look at where it’s commonly used nothing too technical.

AI visual inspection can do a lot of heavy lifting, but getting it running smoothly isn’t always straightforward. Most companies don’t talk about the early hiccups, but they’re pretty normal when you start using any new tech. Here’s the kind of stuff that tends to show up.

Most of the problems that show up with AI visual inspection aren’t “deal breakers.” They’re more like things you adjust as you go. Here’s how companies usually smooth out the rough spots nothing too technical.

AI can make inspections easier, but it also brings a few things companies need to handle carefully. Nothing complicated just practical concerns that come up when new tech enters the workplace.

The discussion of AI Visual Inspection has some mystery around it. However, most people who are new to the topic just do not understand it. It is common to summarize it this way.

AI inspection is already helpful today, but the next few years will make it even more practical. Nothing futuristic or confusing just smarter tools that learn faster and fit into everyday factory work more naturally.

Right now, AI needs a bit of training before it becomes reliable. In the future, these systems will learn on the job. As new products or defect types show up, the AI improves on its own instead of waiting for someone to retrain it manually.

More inspection systems will share data across different plants or locations. That means one factory can learn from another, and updates can roll out instantly without touching every single machine. It also helps keep quality levels consistent everywhere.

Factories won’t choose between humans and AI they’ll use both together. AI handles the repetitive spotting, and humans decide what to do next. This teamwork is becoming the standard approach because it keeps things accurate and practical.

With the increased adoption of AI into various sectors, it is becoming apparent that less items have to be produced, disassembled or refurbished. This is because AI detects any complications found within a production piece more efficiently. This ultimately reduces the amount of raw materials used, along with the amount of energy and time consumed. Organizations are now implementing AI into their structures not only to improve the precision of their work, but also to achieve their eco friendly initiatives without any setbacks to their productivity.

AI visual inspection isn’t some far off futuristic idea anymore it’s slowly becoming part of everyday factory work. As products move faster and expectations keep going up, it’s getting harder for teams to rely only on manual checks. Tools that can spot small defects, keep the quality steady, and alert people before things get out of hand make the whole process a lot easier. AI visual inspection doesn’t take over the job; it just helps people do it with fewer surprises and less stress. And as industries shift toward cleaner production and tighter standards, having a system that adapts and learns along the way will matter even more. Companies that start early simply give themselves a smoother path into the future.