Introduction

The oil and gas industry operates some of the world's most complex and hazardous infrastructure—thousands of kilometers of pipeline running through remote terrain, offshore platforms exposed to corrosive marine environments, and refineries where a single undetected equipment fault can escalate into a catastrophic failure within hours.

Traditional inspection methods—human inspectors climbing rigs, manually sampling pipelines, and reviewing handwritten maintenance logs—were designed for a different era. They cannot scale to the demands of modern operations, they expose workers to unnecessary risk, and they generate inspection data that is too sparse and too slow to drive proactive decisions.

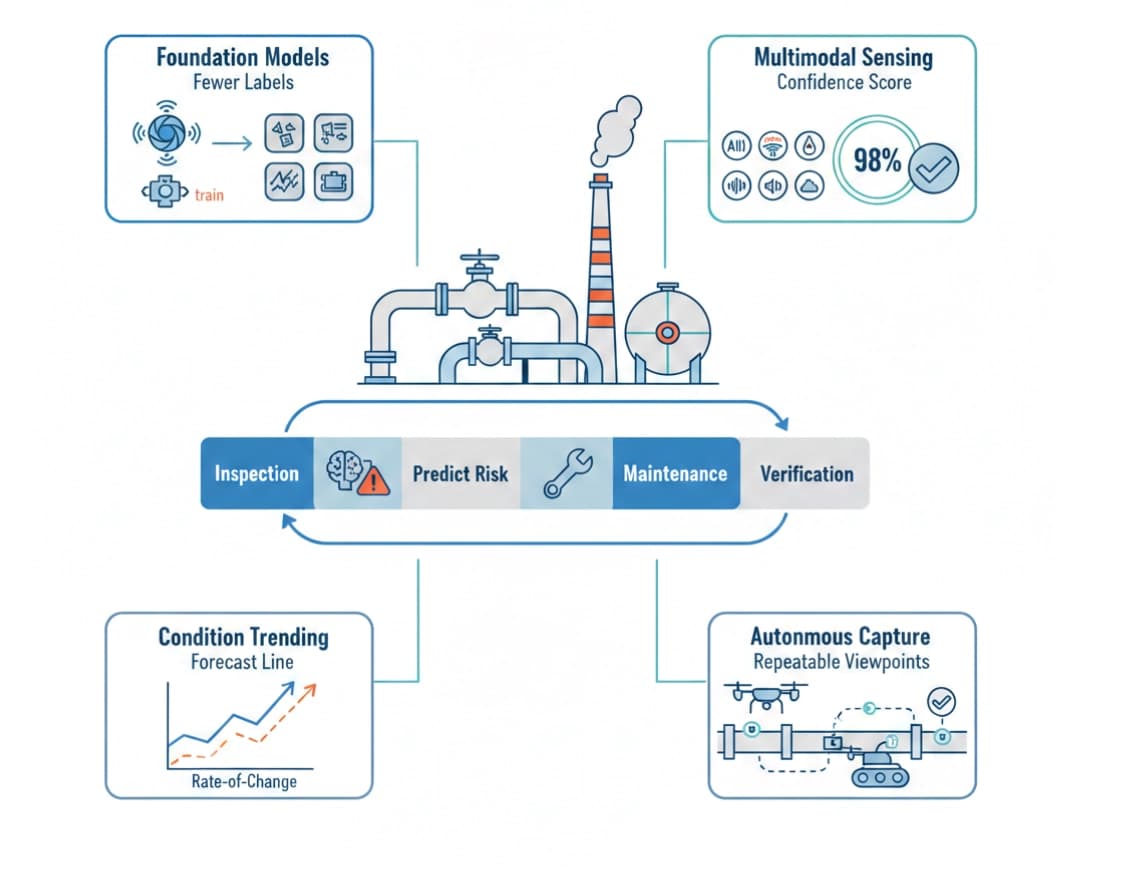

AI visual inspection changes this equation. By combining high-resolution imaging with machine learning models trained on industry-specific defect data, AI inspection systems can assess the structural integrity of assets continuously, accurately, and without putting a single person in harm's way.

This guide covers everything operators, asset managers, and HSE professionals need to understand about AI visual inspection in oil and gas: what it is, where it delivers the most value, how leading operators are deploying it, and what the technology looks like in practice across upstream, midstream, and downstream environments.

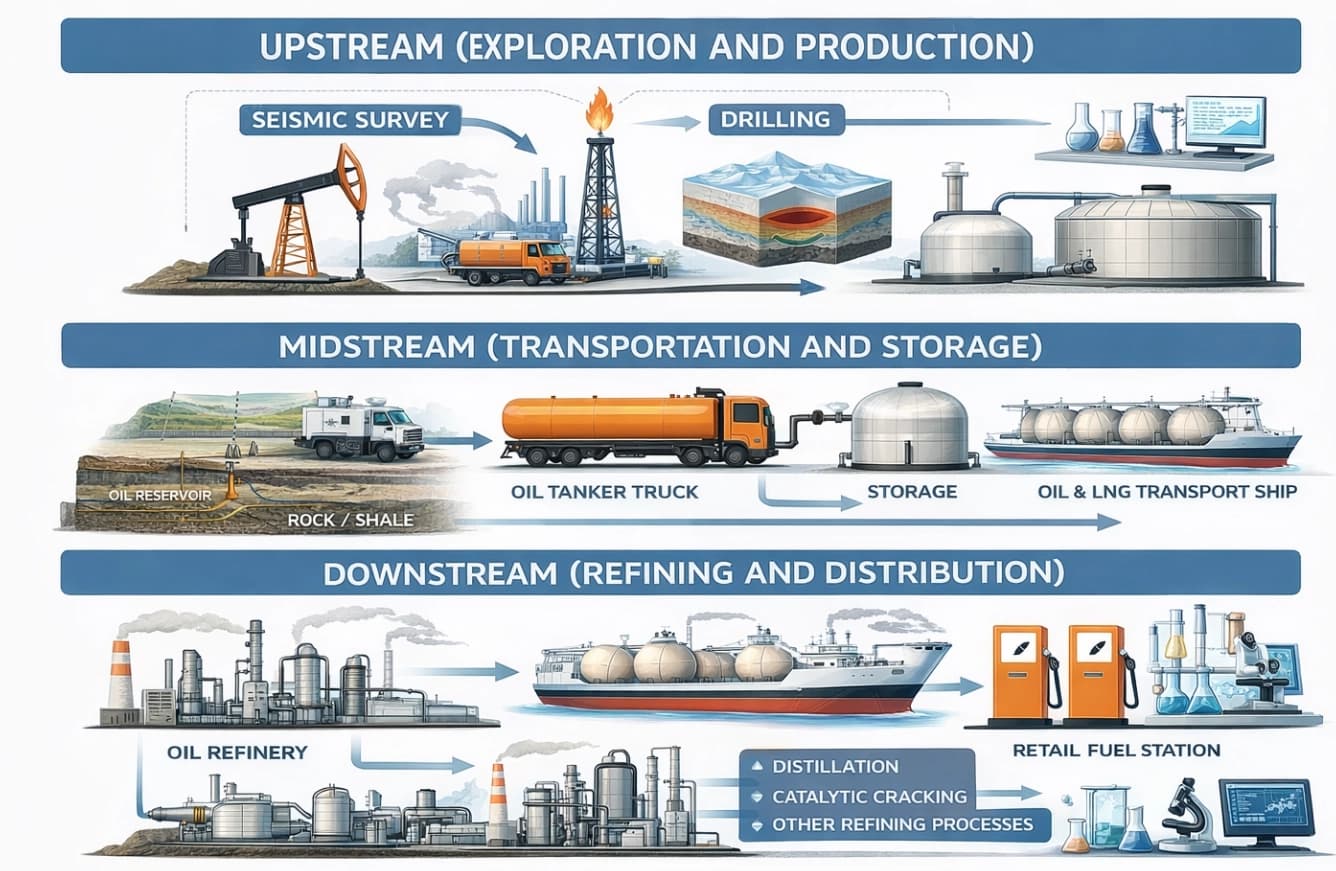

Understanding the Three Sectors of Oil and Gas and Where AI Inspection Fits

Oil and gas operations span three interconnected sectors, each with distinct asset types, inspection challenges, and risk profiles. AI visual inspection applies differently in each—but the common thread is the same: replacing slow, expensive, and risk-prone manual inspection with continuous, automated, data-driven monitoring.

1. Upstream (Exploration and Production)

Upstream operations involve drilling, well completion, and hydrocarbon extraction—often in the world's most remote and hostile environments. Offshore platforms in the North Sea, Gulf of Mexico, and Southeast Asian waters face constant exposure to saltwater corrosion, mechanical fatigue from wave loading, and extreme temperature cycling.

Manual inspection in these environments is both dangerous and logistically expensive. Sending inspection teams to offshore rigs requires helicopter transport, confined-space entry protocols, and extended site shutdowns. Coverage is inevitably partial—inspectors can realistically assess a fraction of the total surface area that requires monitoring.

AI visual inspection addresses this through drone-mounted camera systems that can systematically survey an entire platform in a fraction of the time, ROV (Remotely Operated Vehicle) systems for subsea pipeline and riser inspection, and fixed camera networks that provide continuous structural health monitoring of critical nodes. Machine learning models trained on corrosion, fatigue cracking, and coating failure imagery can identify early-stage defects with a sensitivity and consistency that manual review cannot match.

Key Risk:

Structural failure of offshore risers or production trees can cause blowouts. AI inspection systems are increasingly integrated into structural health monitoring programme as a first line of early-warning detection.2. Midstream (Transportation and Storage)

Midstream infrastructure—pipelines, compressor stations, storage tanks, and LNG terminals—forms the distribution backbone of the oil and gas value chain. Pipeline networks in major producing nations span hundreds of thousands of kilometers, making comprehensive manual inspection physically impossible at meaningful frequency.

The consequences of midstream failures are high-profile and costly. Pipeline leaks cause environmental contamination, regulatory sanctions, and reputational damage. Storage tank failures result in product loss, fire risk, and potential groundbreaking environmental liability. Inspection frequency in manual programme is typically annual or biennial—far too infrequent to catch the slow corrosion and stress patterns that precede failures.

AI inspection in midstream combines fixed inspection stations along pipeline corridors, drone surveys of above-ground pipeline sections, satellite-based change detection for buried pipelines, and automated storage tank inspection using drone-mounted cameras and thermal imaging. These systems can assess corrosion progression continuously, detecting changes between inspection cycles that manual annual checks would miss entirely.

Industry Data:

The Pipeline and Hazardous Materials Safety Administration (PHMSA) reports that corrosion is the leading cause of pipeline incidents in the US, accounting for approximately 23% of reported failures. Early-stage corrosion detection is the single highest-value application of AI visual inspection in midstream operations.3. Downstream (Refining and Distribution)

Downstream operations refine crude oil into finished products—gasoline, diesel, jet fuel, petrochemicals—and distribute them to end markets. Refineries are among the most complex industrial facilities in existence, containing thousands of discrete assets: heat exchangers, distillation columns, pumps, compressors, valves, furnaces, and instrumentation.

Quality and equipment reliability are the primary inspection concerns downstream. Equipment failure in a refinery can cause process disruptions, product quality failures, and in serious cases, fires or explosions. Regulatory oversight is intensive, with frequent audits against API, OSHA, and regional environmental standards.

AI inspection in downstream environments covers automated equipment defect detection (detecting heat discolouration, surface cracking, and seal failures in rotating equipment), real-time PPE compliance monitoring using computer vision to verify that workers in hazardous zones are properly equipped, and product quality inspection at distribution points. The data-rich environment of a modern refinery, with its existing sensor infrastructure, makes it particularly well-suited to AI-augmented inspection programme.

Key Benefits of AI Visual Inspection for Oil and Gas Operations

The business case for AI-based inspection in oil and gas is built on six pillars, each addressing a specific operational cost or risk that manual inspection programme cannot adequately control.

1. Superior Defect Detection Accuracy

In field conditions—varying light, weather, access constraints—human inspector accuracy for detecting early-stage surface defects typically falls in the 60–70% range. AI computer vision models trained on industry-specific defect imagery consistently achieve 95%+ detection rates for the defect types they are trained on, and critically, that accuracy does not degrade with fatigue, shift length, or environmental distraction.

The detection advantage is most pronounced for the defect types that precede catastrophic failures: micro-cracking, coating disbondment, early-stage pitting corrosion, and weld toe fatigue—all visible at sub-millimetre scales in high-resolution imagery but consistently missed by visual inspection under production conditions.

2. Faster, More Comprehensive Inspection Coverage

A manual inspection team assessing a large offshore platform typically requires 2–4 weeks for a thorough survey. A drone-based AI inspection system can complete the same coverage in 8–16 hours. For pipeline inspection, the efficiency differential is even more pronounced: AI-equipped drones can inspect 100+ kilometres per day versus the physical limitations of foot patrol or vehicle-based manual inspection.

This speed advantage is not just about efficiency—it changes the inspection frequency equation. When inspection is faster, it can be conducted more often. Assets that were inspected annually under manual programmes can be assessed quarterly or monthly under AI regimes, dramatically compressing the window between defect onset and detection.

3. Elimination of Worker Safety Risk

Oil and gas inspection is statistically one of the most hazardous occupational activities in the energy sector. Inspectors working in confined spaces, at height on offshore structures, in H2S-present environments, or in live process areas face injury and fatality risks that are orders of magnitude above general industrial averages.

AI-based inspection directly reduces this exposure. When a drone can survey a flare stack, a ROV can inspect a subsea riser, or a fixed camera network can monitor a pressurised vessel, there is no need to send a human inspector into the same location. This is not a marginal benefit—it represents a fundamental redesign of how inspection risk is managed.

Safety Benchmark:

The International Association of Oil and Gas Producers (IOGP) reports that inspection-related activities account for a meaningful portion of oil and gas workplace fatalities annually. AI inspection systems eliminate or substantially reduce the most hazardous inspection activities.4. Predictive Maintenance Capability

The transition from scheduled maintenance (time-based, regardless of actual asset condition) to predictive maintenance (condition-based, triggered by data) is one of the highest-value operational improvements available to oil and gas operators. Unplanned shutdowns in refining and production environments cost between $500,000 and $1,000,000+ per day when lost production, labour, and emergency procurement are fully accounted for.

AI visual inspection enables predictive maintenance by providing continuous, structured data about asset condition. When corrosion rates, crack propagation, or coating degradation are tracked systematically over time, maintenance teams can predict when an asset will reach its intervention threshold with sufficient lead time to plan maintenance during scheduled turnarounds—rather than reacting to emergency failures.

5. Automated Compliance and Regulatory Documentation

Oil and gas operations are subject to intensive regulatory oversight across every jurisdiction in which they operate. API 510, API 570, API 653, ATEX, OSHA PSM, and regional environmental regulations all require documented inspection programmes with defined frequencies, acceptance criteria, and data retention requirements.

Manual inspection programmes generate paper-based or spreadsheet records that are difficult to aggregate, difficult to audit, and difficult to defend under regulatory scrutiny. AI inspection systems generate comprehensive, timestamped digital records for every inspection event—including the raw imagery, the model's classifications, and any recommended actions. These records are immediately available, searchable, and structured in formats compatible with regulatory reporting.

6. Long-Term Cost Efficiency

The upfront investment in AI inspection systems—cameras, drones, software platforms, and model training—is significant. But the long-term cost mathematics consistently favour AI over expanding manual inspection programmes. Labour costs for qualified NDT inspectors are high and rising. Travel, logistics, and access costs for remote or offshore inspections add substantially to programme costs. And the cost of failures that manual programmes miss—recalls, environmental remediation, emergency shutdowns—dwarfs the capital cost of preventive inspection systems.

Most oil and gas operations that deploy AI visual inspection at meaningful scale report positive ROI within 18–36 months, driven primarily by avoided unplanned downtime and reduced inspection labour costs.

AI Visual Inspection Use Cases in Oil and Gas: Real Applications

The following use cases represent the highest-value, most widely deployed applications of AI visual inspection in oil and gas operations globally. Each addresses a specific inspection challenge where manual methods have historically underperformed.

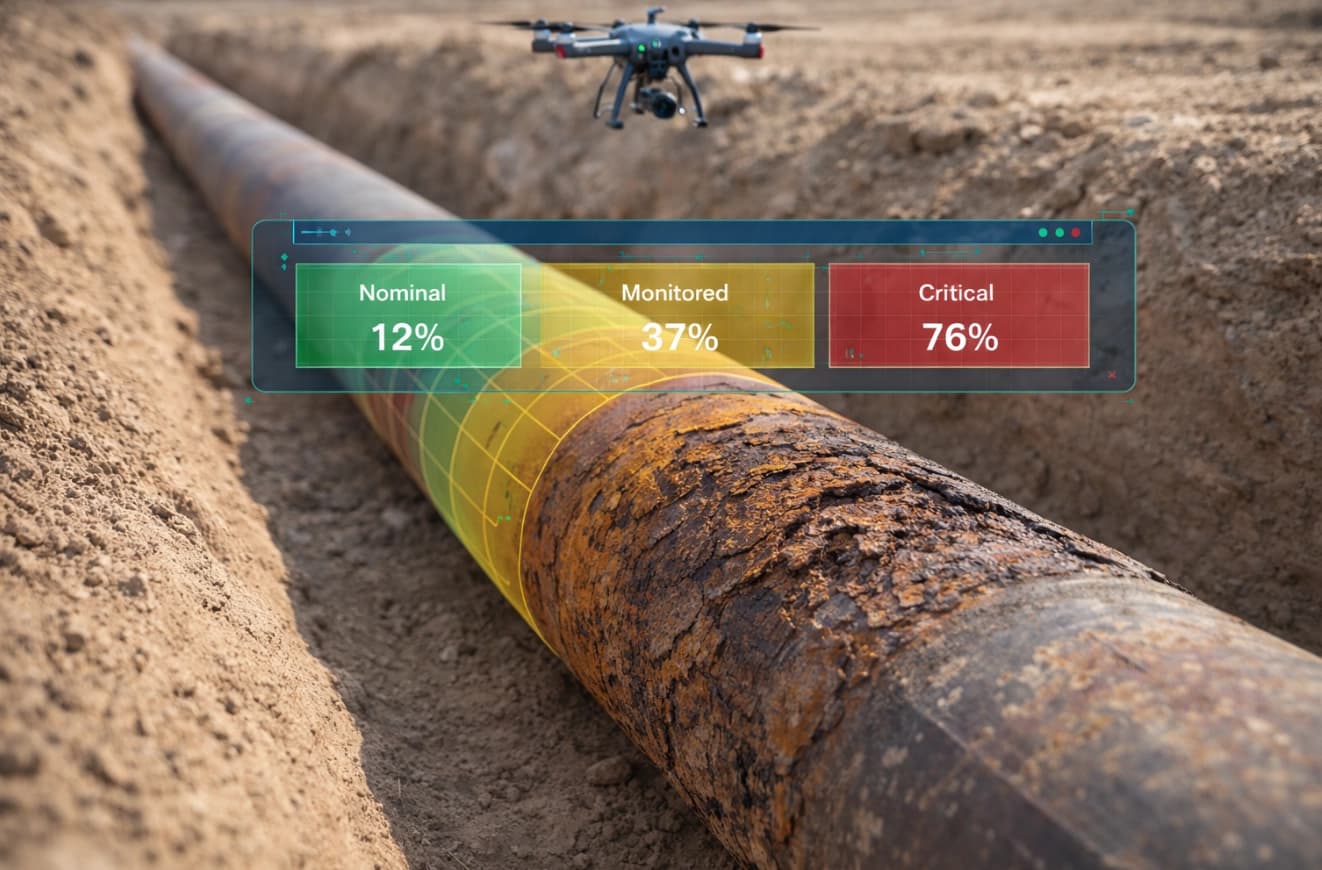

Use Case 1: Pipeline Corrosion Detection and Integrity Management

Pipeline corrosion—both external (from soil and atmospheric conditions) and internal (from process fluids)—is the leading cause of pipeline integrity failures globally. Traditional inspection programmes rely on periodic intelligent pigging, manual patrol inspection, and scheduled coupon analysis to assess corrosion rates. These methods provide point-in-time data at infrequent intervals, missing the dynamic progression of corrosion between inspection cycles.

AI visual inspection for pipeline corrosion operates at multiple scales. External above-ground inspection uses drone-mounted high-resolution cameras combined with AI corrosion classification models to assess pipeline surface condition across large networks rapidly. Fixed camera stations at critical nodes provide continuous monitoring of high-risk locations. Thermal imaging integrated with AI analysis can detect active leaks and process anomalies that surface inspection would miss.

The AI models classify corrosion by type (pitting, general, crevice, galvanic), severity (minor, moderate, critical), and location—generating a structured corrosion map of the asset that can be trended over time. When corrosion rate at a specific location exceeds a defined threshold, the system automatically generates an inspection alert and recommended intervention timeline.

• Business Impact — Defect detection

Corrosion detected at micro-scale, 60–90 days before it would be visible in standard manual inspection.

• Business Impact — Failure prevention

Operators report 40–60% reduction in corrosion-related pipeline incidents following AI monitoring deployment.

• Business Impact — Cost

Early intervention at controlled corrosion stages costs 5–10x less than emergency repair of a failure.

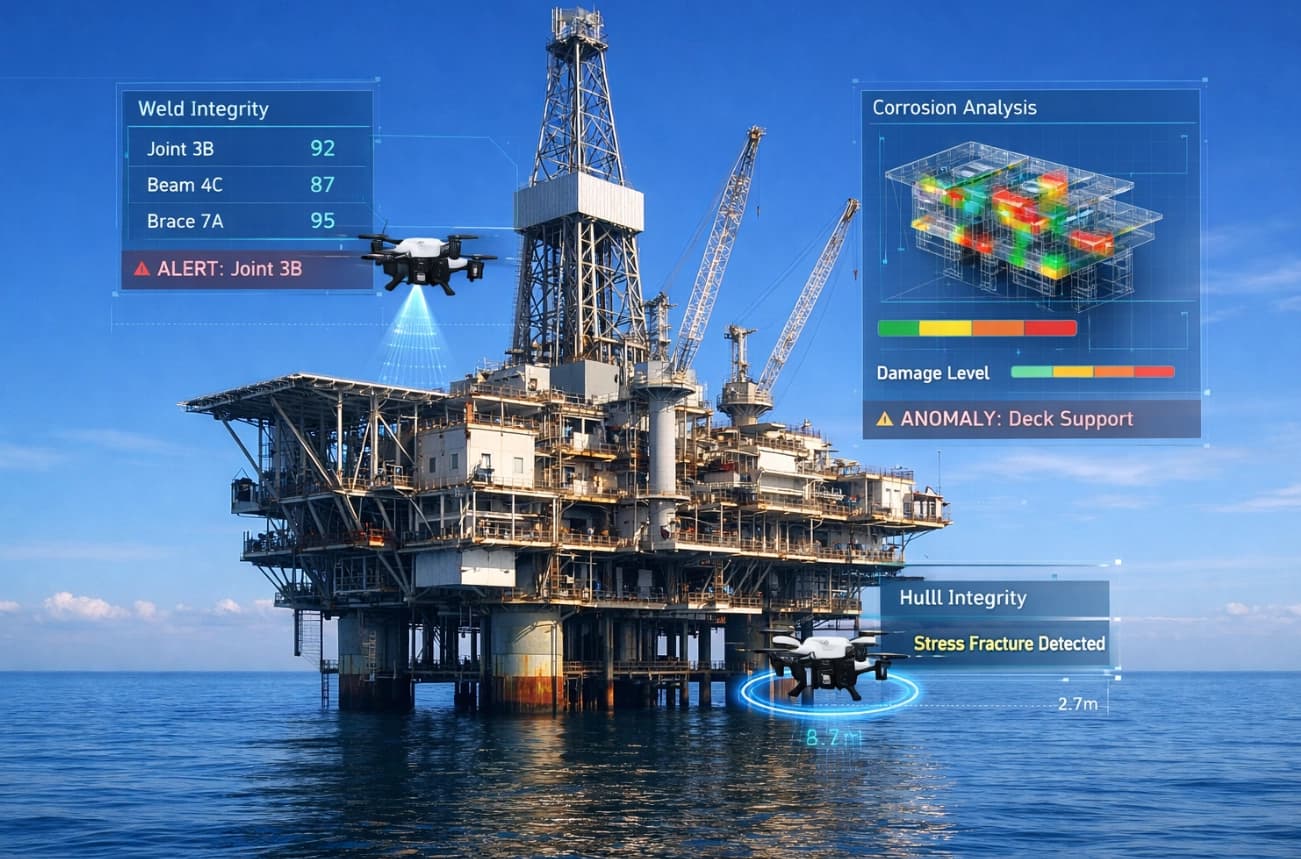

Use Case 2: Offshore Platform Structural Monitoring and Inspection

Offshore platforms are among the most complex and high-value assets in the oil and gas industry, typically representing $1–5 billion in capital investment. Their structural integrity is critical not only to production continuity but to the safety of the hundreds of people who live and work on them. The combination of marine corrosion, wave fatigue loading, and the practical difficulty of inspecting every structural node makes offshore platforms one of the most compelling applications for AI-based inspection.

AI visual inspection for offshore structures typically deploys autonomous inspection drones that follow pre-programmed survey routes covering the topsides, risers, and hull. The drones capture high-resolution imagery that is processed by AI models trained to identify structural anomalies including weld cracking, coating failures, biofouling on subsea structures, and marine growth on conductors.

The data from each survey is compared against baseline imagery from previous inspections, with AI anomaly detection algorithms flagging areas of change for engineering review. This change-detection capability is particularly valuable because many structural defects are not absolute failures—they are progressive deterioration trends that require engineering judgement about intervention timing.

Shell case example:

Shell reported a 70% reduction in offshore inspection time after deploying drone-based AI visual inspection for storage tank and platform surveys, with a simultaneous increase in defect detection coverage.Safety benefit:

Eliminating human rope-access inspection of offshore structures removes workers from one of the most hazardous inspection activities in the industry.

Use Case 3: Above-Ground Storage Tank Inspection and Monitoring

Above-ground storage tanks (ASTs) holding crude oil, refined products, or petrochemicals represent significant environmental and financial liability if structural integrity is compromised. API Standard 653 mandates regular inspection of tank shells, roofs, floors, and associated piping—but the scale of tank farm infrastructure at major terminals makes comprehensive manual inspection resource-intensive and logistically complex.

AI-based tank inspection uses drone-mounted cameras to survey tank exteriors systematically, with AI models classifying surface condition by corrosion type, severity, and affected area. Internal tank inspection, which traditionally requires product removal, confined-space entry, and significant downtime, is increasingly being supplemented by robotic crawlers equipped with computer vision systems that can inspect tank floors and shells while the tank remains partially in service.

The AI system generates a condition report for each tank that quantifies the proportion of surface area in each condition category, identifies priority areas for maintenance attention, and trends condition changes between inspection cycles. This enables maintenance teams to prioritize intervention across large tank farms based on actual condition data rather than blanket inspection schedules.

Operational Insight:

Tank farms with 100+ tanks can now be systematically assessed in days rather than weeks. The structured condition data generated enables risk-based inspection planning that optimises maintenance spend across the portfolio.

Use Case 4: Worker Safety and PPE Compliance Monitoring

Personal Protective Equipment (PPE) compliance is one of the most consistently challenging aspects of oil and gas HSE management. Workers in active process areas are required to wear helmets, high-visibility vests, safety glasses, gloves, and respiratory protection depending on zone classification—but monitoring compliance across large facilities with rotating workforces is impossible to achieve through manual supervision alone.

AI computer vision systems installed at facility entry points and throughout operational areas continuously monitor PPE compliance in real time. The AI models detect the presence or absence of each required PPE item for each person visible in the camera frame, generating immediate alerts when violations occur and producing compliance reports that document adherence rates by zone, shift, and time period.

The compliance data generated by these systems has value beyond immediate safety management. It provides the documented evidence base that regulatory inspectors require, identifies systemic compliance challenges in specific areas or with specific equipment types, and creates accountability for workplace safety culture that verbal supervision cannot achieve.

Regulatory value:

Automated PPE compliance records satisfy OSHA and regional safety regulatory documentation requirements without manual record-keeping overhead.Cultural impact:

Visible AI monitoring systems consistently improve voluntary compliance rates—the awareness of being monitored changes behaviour even before any violation is flagged.Use Case 5: Refinery Equipment Inspection and Predictive Maintenance

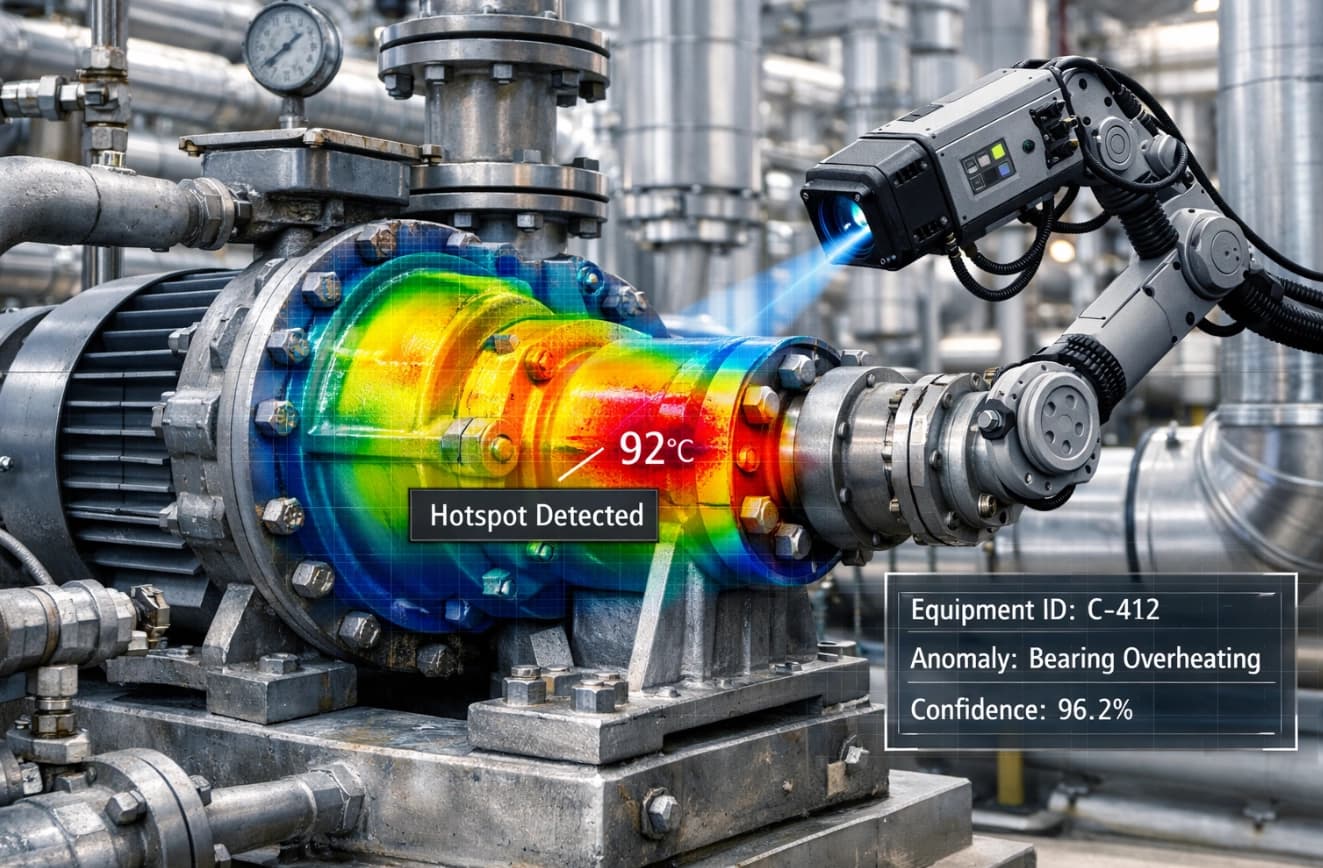

Refineries contain thousands of pieces of rotating and static equipment that require regular inspection to maintain reliability and safety. Heat exchangers foul and corrode; pump seals degrade; valve seats erode; furnace tubes develop hot spots; pressure vessels experience stress corrosion cracking. Identifying these issues before they cause process disruptions requires inspection sensitivity and frequency that manual programme cannot practically deliver.

AI visual inspection in refinery environments integrates high-resolution cameras with thermal imaging to detect both surface defects and thermal anomalies indicating internal problems. AI models trained on refinery-specific equipment failure modes can identify early indicators of pump bearing wear from vibration patterns captured on video, detect furnace tube hot spots from thermal imagery, and flag pressure relief valve seat erosion from close-range inspection imagery captured by fixed cameras or inspection robots.

The inspection data feeds directly into the predictive maintenance workflow: when the AI system detects an early-stage defect, it generates a maintenance work order with priority classification, recommended action, and estimated time-to-failure projection. Maintenance teams can then plan intervention during scheduled turnarounds rather than responding to emergency breakdowns.

Oil and Gas AI Inspection: What Industry Leaders Are Demonstrating

The transition to AI-based inspection in oil and gas is not theoretical. Leading operators have deployed these systems at operational scale, and their results provide a useful benchmark for what is achievable.

Major IOCs: Scaling AI Inspection Across Global Asset Portfolios

The largest international oil companies have invested heavily in AI inspection infrastructure, driven by the scale efficiencies available when systems can be deployed across hundreds of assets simultaneously. The pattern across major IOC deployments is consistent: initial proof-of-concept pilots on one or two asset types, followed by systematic scaling once ROI is validated, with a focus on integrating AI inspection data into existing enterprise asset management systems.

The key outcome reported across these programmes is not just defect detection improvement—it is the shift to data-driven maintenance planning. When inspection generates structured, comparable data across an asset portfolio, maintenance teams can allocate resources based on actual risk rather than default schedules, typically achieving 15–25% reduction in total maintenance spend while improving asset reliability.

Offshore Operators: Drone Inspection as the New Standard

Offshore operators—particularly in the North Sea and Gulf of Mexico—have been early and enthusiastic adopters of drone-based AI inspection, driven by the compelling combination of safety benefit and operational economics. Helicopter transport costs for manual inspection teams are substantial; drone systems eliminate or substantially reduce this overhead while delivering higher inspection frequency and coverage.

The offshore sector has also led in developing the inspection methodology and regulatory framework for drone-based inspection. Classification societies including DNV and Lloyd's Register have developed acceptance criteria for AI-assisted inspection findings, enabling drone inspection data to be used for statutory survey purposes in an increasing range of applications.

National Oil Companies: AI Inspection and Local Capability Building

National oil companies in the Middle East, West Africa, and Southeast Asia have adopted AI visual inspection with a dual agenda: improving operational performance and building domestic digital technology capability. These deployments typically involve partnerships with AI inspection technology vendors to develop models trained on locally relevant operating conditions and asset types, creating inspection capabilities that are tailored to the specific corrosion environments, equipment populations, and regulatory requirements of each operating context.

Challenges in Implementing AI Visual Inspection in Oil and Gas

The barriers to AI inspection adoption are real and should be addressed honestly. Understanding these challenges is the starting point for developing an implementation strategy that avoids the pitfalls that have derailed early-stage deployments.

• Training Data Scarcity

AI models require large volumes of annotated defect imagery to achieve reliable performance. In oil and gas, where defects are rare events by design, accumulating sufficient training data for model development can take years. Operators addressing this challenge use synthetic data generation, transfer learning from related industrial domains, and collaborative data-sharing arrangements with technology partners.

• Legacy System Integration

Most oil and gas operators manage inspection data in legacy enterprise asset management and maintenance management systems that were not designed to ingest AI-generated inspection data. Integration requires API development, data schema alignment, and workflow redesign—all of which require investment and cross-functional coordination between operations, IT, and maintenance teams.

• Regulatory Acceptance

Inspection standards in oil and gas are set by regulatory bodies and classification societies that have historically based their requirements on human-performed inspection methods. Obtaining regulatory acceptance for AI-assisted inspection findings—particularly for statutory safety inspections—requires engagement with regulators to demonstrate that AI inspection meets or exceeds the performance standards of manual inspection.

• Workforce Capability Gap

Effective AI inspection implementation requires personnel who understand both the inspection requirements of oil and gas operations and the principles of computer vision and machine learning. This combination of domain expertise and AI literacy is scarce. Operators who invest in training existing inspection engineers in AI methods, rather than replacing them with data scientists who lack domain knowledge, consistently achieve better implementation outcomes.

• Cybersecurity and Connectivity

AI inspection systems that connect to cloud platforms or enterprise networks expand the cybersecurity attack surface of oil and gas operations. In environments where a successful cyberattack on operational technology could have physical consequences, this is a non-trivial concern. Effective implementation requires segmented network architecture, encrypted data transmission, and rigorous access controls.

The Future of AI Visual Inspection in Oil and Gas: Emerging Trends

The technology and operational practice of AI visual inspection in oil and gas is evolving rapidly. The capabilities available in 2025 are meaningfully more advanced than those deployed five years ago, and the trajectory of development suggests the pace of change will continue.

• Edge AI for zero-latency detection

Moving AI inference directly to the camera or drone removes dependence on network connectivity and cloud processing, enabling millisecond-scale defect detection in remote locations where bandwidth is limited. This is particularly significant for subsea and arctic operations.

• AI-powered digital twins

The convergence of AI inspection data with digital twin models creates dynamic asset representations that reflect real-time physical condition. When inspection data from a pipeline segment updates the corresponding digital twin model, operators can run failure simulations and remaining-life calculations based on current measured condition rather than design assumptions.

• Autonomous inspection fleets

The next generation of inspection drones will operate autonomously—launching, flying pre-programmed survey routes, landing, recharging, and reporting without human intervention. Persistent autonomous monitoring of critical assets becomes operationally feasible, transforming inspection from a periodic event to a continuous process.

• Multispectral and hyperspectral imaging

Standard visible-spectrum cameras detect surface-visible defects. Multispectral and hyperspectral imaging systems detect subsurface material property changes—internal corrosion, coating adhesion loss, and material fatigue—that are invisible to standard camera systems. Integration with AI classification models will substantially expand the defect types detectable through non-invasive inspection.

• Cross-industry model transfer

AI inspection models developed for manufacturing quality control are increasingly adaptable for oil and gas applications, and vice versa. As the pool of available training data grows and transfer learning techniques mature, the cost and time required to develop effective AI inspection models for new asset types will continue to fall.

• ESG-integrated inspection reporting

AI inspection platforms will increasingly generate outputs formatted for direct integration into ESG reporting frameworks, automatically compiling the asset condition, incident, and environmental monitoring data required for GRI, TCFD, and SASB disclosures.

Conclusion: AI Visual Inspection as a Strategic Operational Imperative in Oil and Gas

Oil and gas operators face simultaneous pressure to cut costs, improve safety, meet stricter environmental rules, and prove ESG credibility, while managing ageing, complex infrastructure. Manual inspection alone can’t reliably meet all of these demands at once.

AI visual inspection can: detect defects earlier, inspect more assets more often, reduce human exposure in hazardous environments, and produce structured data for predictive maintenance and regulatory compliance.

The tech is proven, ROI is documented, and regulatory frameworks are advancing quickly. Operators that start now—building training data, integrating with existing systems, and developing internal capability, will reach scale faster and gain a durable operational edge.

The best place to begin is typically the same: the highest-risk asset class where manual coverage is weakest and the cost of a missed defect is greatest. Early data advantage is real, and it compounds.