AI Visual Inspection Overview

AI Visual Inspection in maritime harnesses advanced computer vision, machine learning, and automated imaging systems to revolutionize the inspection of ship hulls, cargo, offshore platforms, and port infrastructure. By analyzing high-resolution images from cameras, drones, and sensors in real time, it detects critical defects such as cracks, corrosion, and leaks with superior accuracy. This automation significantly reduces human error, boosts regulatory compliance, and enables predictive maintenance, transforming traditional, labor-intensive inspections into fast, accurate, and scalable processes that enhance maritime safety, efficiency, and cost-effectiveness.

For shipping, offshore, and port leaders, adopting Automated Visual Inspection is more than just a technological upgrade it is a strategic move towards enhanced safety, cost reduction, and stringent regulatory compliance. In this blog, we explore how AI-powered Visual Inspection is revolutionizing maritime operations by reducing downtime, improving inspection accuracy, enabling predictive maintenance, and ensuring sustainable practices. Discover real-world applications, key benefits, and future trends that position companies to thrive in an increasingly competitive and regulated maritime industry.

How AI Visual Inspection Revolutionizes Maritime Safety

The maritime environment is unforgiving: ships face constant exposure to saltwater, storms, and mechanical stress. Traditional inspections rely heavily on manual observations, meaning subtle defects often go unnoticed until they escalate into critical failures.

AI Visual Inspection transforms this model by embedding automated visual inspection systems into daily operations. Equipped with high-resolution cameras, drones, and sensors, these systems feed visual data into AI defect detection models that analyze images at scale and in real time.

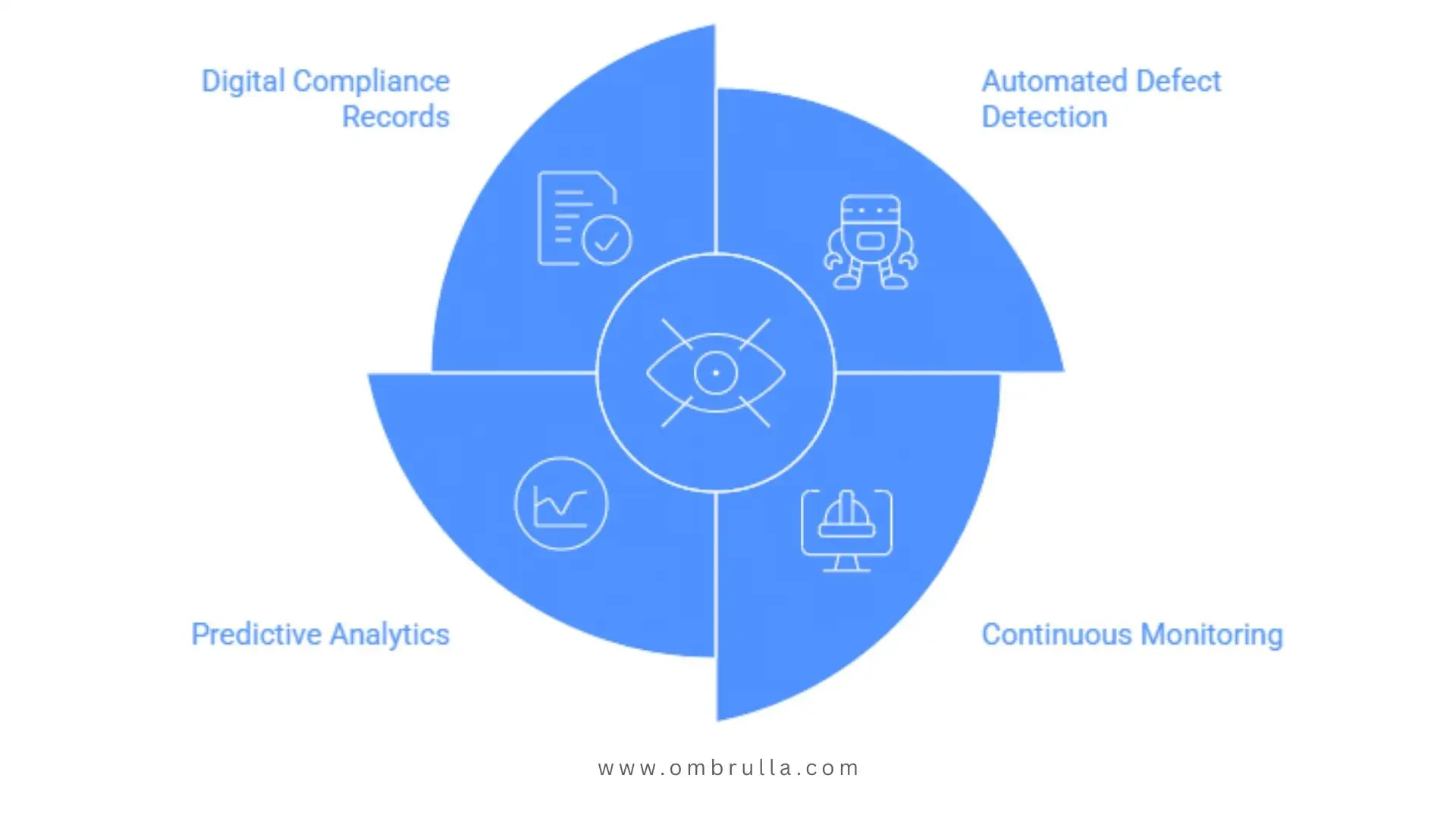

Enhancing Features of AI Visual Inspection

• Digital Compliance Records

Each inspection is stored and traceable, ensuring adherence to IMO and classification society requirements.

• Automated Defect Detection

Identifies welding flaws, rust, cracks, and coating failures invisible to human eyes.

• Predictive Analytics

AI quality control uses historical data to forecast high-risk areas before failure occurs.

• Continuous Monitoring

Ships and rigs are monitored 24/7 with installed AI-powered cameras.

By shifting inspections from reactive to proactive, AI inspection systems strengthen safety, prevent costly accidents, and provide peace of mind to operators and regulators alike.

The Real-World Challenges of Manual Ship Inspections

Despite being standard practice, manual inspections face serious limitations in today’s fast-paced, high-compliance environment:

• Human Error

Fatigue, distraction, and subjective judgment reduce reliability.

• Scalability

Inspecting large vessels, offshore rigs, or global fleets manually is slow and resource-heavy.

• High Costs & Downtime

Vessels often must be docked for checks, disrupting cargo schedules and revenue flow.

• Safety Hazards

Inspectors face risks in confined, underwater, or high-altitude spaces.

• Inconsistent Data

Different inspectors interpret conditions differently, complicating compliance reporting.

The result? Higher costs, increased risks, and uneven inspection standards across fleets. These shortcomings make a strong case for adopting AI computer vision as the backbone of modern inspections.

Benefits of AI Visual Inspection in the Maritime Industry

For maritime operators, the benefits of Visual Inspection AI are game-changing. It not only enhances safety and compliance but also delivers measurable cost savings and improves operational efficiency.

1. Superior Accuracy

AI defect detection identifies micro-cracks, corrosion, and wear that humans often miss, delivering objective and repeatable results.

2. Reduced Costs & Downtime

Automated visual inspection enables inspections while vessels remain in operation, minimizing costly dry-docks and delays.

3. Compliance Assurance

Digital records support audits and ensure adherence to SOLAS, MARPOL, and IMO regulations. This makes AI an essential tool for maritime safety compliance.

4. Fleet-Wide Scalability

AI-powered quality control ensures uniform inspection standards across global fleets, improving reliability and consistency at scale.

5. Predictive Insights

Supports predictive maintenance with AI inspections, helping optimize repair schedules, prevent unexpected failures, and extend asset lifecycles.

Examples of AI Visual Inspection in the Maritime Industry

AI Visual Inspection is already being applied across multiple areas of the maritime industry, from ship hull monitoring to offshore rig inspections. These real-world examples highlight how AI improves safety, reduces downtime, and ensures compliance at every level of operation.

Hull Integrity Monitoring

AI-powered drones and underwater ROVs use machine vision inspection to spot cracks, biofouling, and corrosion during voyages, reducing dry-dock reliance.

Cargo Container Inspection

AI computer vision checks container seals, labels, and structural integrity preventing cargo disputes and improving port turnaround.

Offshore Oil & Gas Platforms

Artificial Intelligence Visual Inspection monitors subsea pipelines, welds, and rig structures for early signs of corrosion and fatigue.

Port Infrastructure

AI-driven inspections of cranes, docks, and loading equipment detect wear and failures early, ensuring smoother port operations and improved safety.

Safety Equipment

Computer vision inspects lifeboats, fire extinguishers, and safety gear to ensure readiness, boosting compliance and crew safety.

Ship Engine Room Monitoring

AI visual inspections monitor engine parts and turbines in real time to detect issues, cut downtime, boost efficiency, and ensure maritime safety.

These examples highlight how AI quality control enhances efficiency across the entire maritime ecosystem.

Applications of AI Visual Inspection in Maritime Inspections

The application of computer vision extends into nearly every area of maritime inspections, delivering a comprehensive quality assurance framework.

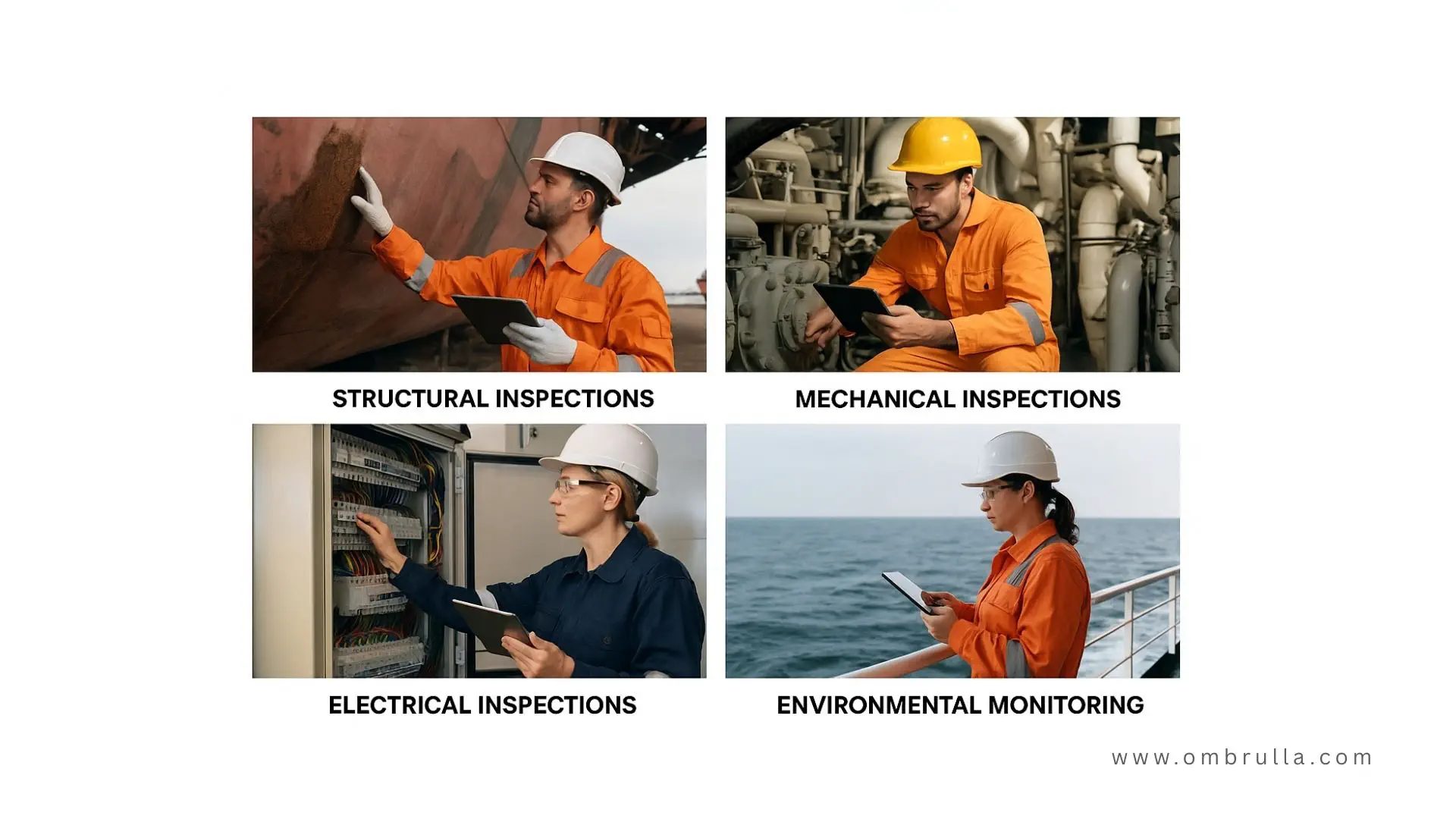

Structural Inspections

• Hulls & Bulkheads

AI detects cracks and deformations early, preventing costly failures. This improves vessel safety and reduces unexpected repair bills.

• Decks & Tanks

By identifying corrosion and fatigue damage, AI reduces downtime and extends asset life. This lowers maintenance costs and boosts fleet availability.

• Shipbuilding Welds

Automated weld verification ensures compliance with industry standards and reduces rework. Stronger welds translate into fewer breakdowns and higher ROI in construction and upkeep.

Beyond structural integrity, ships also rely on critical mechanical systems that demand the same level of precision and reliability.

Mechanical Inspections

• Engines & Turbines

Detecting overheating and leaks early minimizes unplanned breakdowns. This increases operational efficiency and cuts repair expenses.

• Propellers & Pumps

Identifying cavitation damage and imbalance helps maintain fuel efficiency. Better efficiency directly reduces operating costs and ensures smoother voyages.

• Cranes & Port Gear

AI monitoring of gears and hydraulics prevents accidents and downtime. Improved reliability lowers insurance risks and maximizes equipment utilization.

While mechanical safety is essential for smooth operations, environmental monitoring is equally vital to meet global sustainability and compliance standards.

Electrical Inspections

• Power Distribution Systems

AI detects overheating, insulation damage, and loose connections in switchboards and cables. This reduces fire hazards, prevents costly failures, and minimizes downtime.

• Navigation & Communication Equipment

AI monitors radar, sensors, and control panels to ensure reliable performance. Consistent operation improves safety and avoids disruptions at sea.

• Battery & Energy Storage Systems

AI inspection tracks battery health, charging cycles, and potential leaks. Proactive monitoring extends lifespan, lowers replacement costs, and supports sustainable vessel operations.

Environmental Monitoring

• Oil Spill Detection

Real-time monitoring prevents large-scale spills, avoiding environmental fines and reputational damage. Quick response also reduces cleanup costs.

• Ballast Water Treatment

Ensuring compliance with international regulations avoids heavy penalties. Reliable treatment reduces delays at ports and safeguards global trade routes.

• Emission Control

Monitoring exhaust stacks ensures IMO-compliant emissions. Staying compliant helps operators avoid costly violations and strengthens ESG performance.

By covering structural, mechanical, electrical, and environmental aspects, AI inspection systems bring consistency, speed, and accuracy unmatched by manual methods.

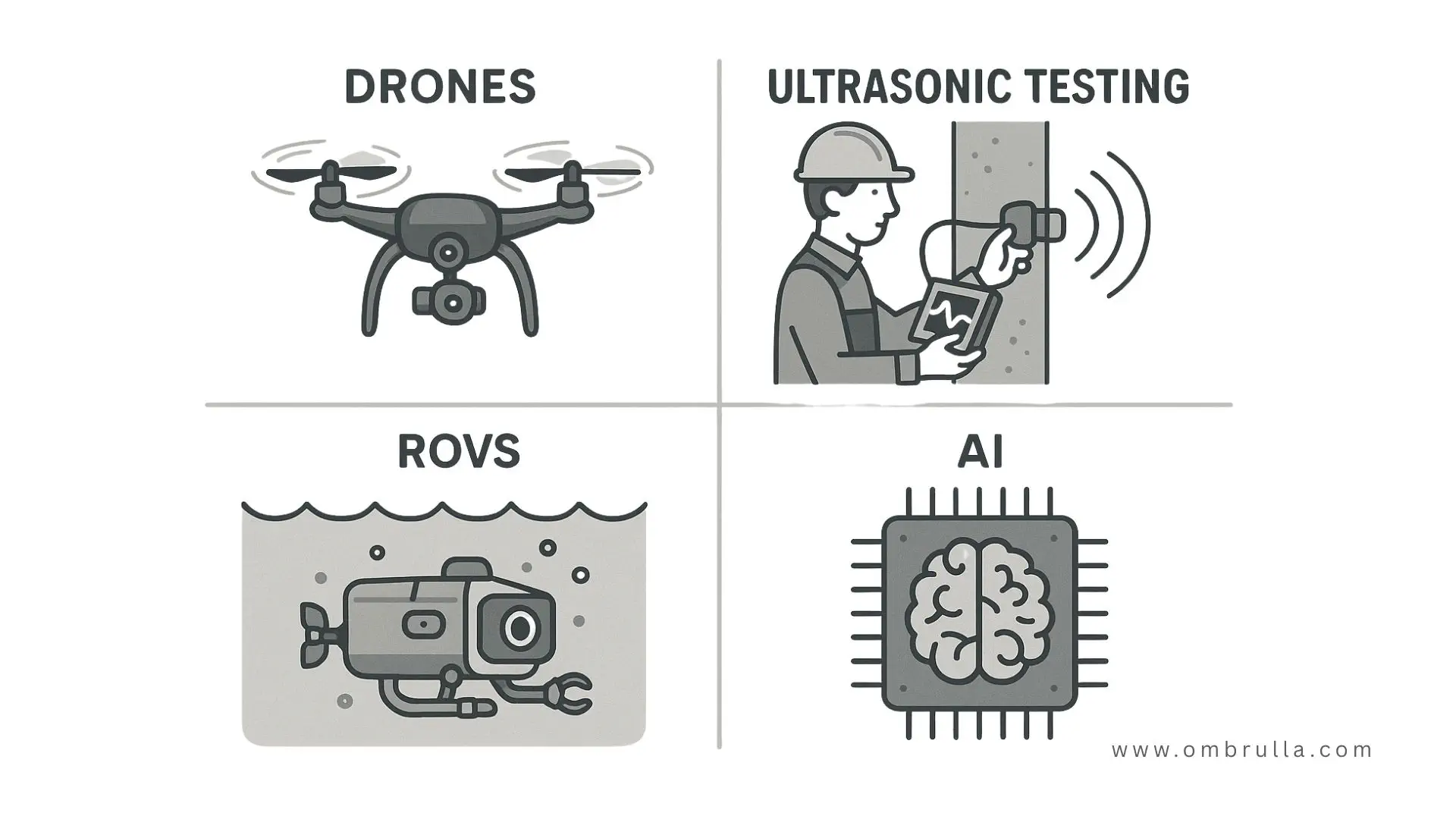

Comparing AI Visual Inspection with Other Technologies

Maritime inspections use various tools, drones, ultrasonic testing (UT), and remotely operated vehicles (ROVs). On their own, these tools are powerful. But combined with Visual Inspection AI, they become transformative.

Drones

• Strengths

Access hard-to-reach areas like hulls and cranes.

• Limitations

Raw images still require human interpretation.

• With AI

Drones with AI computer vision analyze images in real time, detecting cracks or corrosion instantly.

Ultrasonic Testing (UT)

• Strengths

Detects internal flaws and corrosion.

• Limitations

Time-consuming and technician-dependent.

• With AI

AI defect detection identifies stress points and predicts failure risks, reducing unnecessary testing.

ROVs

• Strengths

Inspect underwater hulls and offshore rigs.

• Limitations

High cost, slow, and dependent on expert analysis.

• With AI

ROVs with automated visual inspection deliver instant subsea defect detection and reporting.

Why AI is Superior

• Consistency

Eliminates subjective interpretation.

• Speed

Provides instant results versus lengthy manual analysis.

• Scalability

Enables inspection of entire fleets worldwide.

• Predictive Power

Goes beyond detection to forecast future issues.

Artificial Intelligence Visual Inspection doesn’t replace these tools it enhances them, creating a unified, future-ready inspection ecosystem.

AI and Environmental Sustainability in Maritime

Sustainability has become a defining priority for the maritime industry. With the International Maritime Organization (IMO) setting ambitious decarbonization targets, ship operators and offshore companies are under increasing pressure to reduce emissions, prevent environmental incidents, and demonstrate ESG compliance. Here, AI Visual Inspection plays a critical role by combining efficiency with environmental responsibility.

Reducing Emissions through Efficiency

One of the most effective ways to cut emissions is to keep vessels operating at peak efficiency. Hull fouling, corrosion, and engine inefficiencies can dramatically increase fuel consumption. AI defect detection continuously monitors hull surfaces, propellers, and engine performance. By identifying early signs of deterioration, Visual Inspection AI enables timely cleaning, repairs, or replacements reducing drag, lowering fuel use, and cutting CO₂ emissions.

Preventing Oil Spills and Chemical Leaks

Environmental disasters such as oil spills or chemical leaks not only damage ecosystems but also lead to heavy fines and reputational damage. Automated Visual Inspection powered by AI computer vision allows early detection of pipeline cracks, seal failures, and storage tank leaks. This proactive approach ensures hazardous materials are contained before they cause marine pollution, strengthening compliance with MARPOL and other international safety frameworks.

Minimizing Waste through Predictive Maintenance

Traditional maintenance often follows a “replace-on-schedule” approach, which can lead to premature disposal of usable equipment. With AI quality control, maintenance is optimized based on actual asset condition. Predictive models identify components nearing failure, allowing targeted interventions. This reduces unnecessary replacements, lowers material waste, and extends equipment lifecycles supporting both cost efficiency and sustainability.

Meeting IMO Decarbonization Goals

The IMO has set clear objectives for reducing greenhouse gas emissions in maritime operations. AI inspection systems assist by providing traceable, verifiable digital records of emission controls, ballast water treatment, and fuel efficiency. This creates transparency, simplifies audits, and demonstrates compliance to regulators and stakeholders. By embedding Artificial Intelligence Visual Inspection into daily operations, shipping companies can actively contribute to global decarbonization initiatives.

By combining efficiency with environmental sustainability and responsibility, AI inspection systems align operations with both business goals and regulatory demands.

The Future of Maritime Inspections

The future of AI computer vision in maritime inspections is rapidly evolving, driven by the need for greater safety, compliance, and operational efficiency. Emerging technologies are converging to create smarter, faster, and more autonomous inspection systems that redefine how the maritime sector approaches maintenance and risk management.

1. IoT Integration

The combination of IoT sensors and AI inspection systems will enable continuous, real-time monitoring of vessels and port infrastructure. Data collected from hull sensors, engine monitors, and cargo systems will be instantly analyzed using AI Visual Inspection models, allowing for proactive identification of anomalies and immediate corrective action. This level of integration ensures consistent performance and compliance across entire fleets.

2. Edge AI for Instant Analysis

With edge AI, defect detection and data processing happen directly onboard ships and rigs rather than relying on cloud connectivity. This means inspections are completed in real time, even in remote areas with limited internet access. Faster analysis reduces downtime, enhances safety, and supports mission-critical decision-making at sea.

3. Autonomous Inspection Robots

The future will see autonomous drones and ROVs equipped with Visual Inspection AI operating independently of human pilots. These robots will conduct underwater hull inspections, check hard-to-reach port infrastructure, and monitor offshore rigs continuously. By eliminating human involvement in dangerous environments, companies not only improve safety but also achieve higher inspection coverage at lower costs.

4. Cloud-Based Fleet Oversight

Global shipping companies manage fleets that span continents. With cloud-based inspection systems, data from AI inspections will be aggregated and benchmarked across fleets worldwide. This centralized oversight allows operators to compare vessel conditions, standardize quality control practices, and deploy predictive maintenance strategies at scale.

5. Predictive Maintenance Ecosystems

Perhaps the most transformative trend is the creation of predictive maintenance ecosystems. Here, AI defect detection not only identifies current issues but also forecasts potential failures long before they occur. By analyzing patterns of wear, stress, and environmental exposure, AI helps managers schedule proactive repairs, reducing downtime and extending asset life cycles.

In short, the future of maritime inspections with AI computer vision is one of autonomy, intelligence, and integration. These advancements will enable shipping companies to operate with greater safety, compliance, and efficiency while reducing costs and environmental impact.

AI Visual Inspection for Maritime – FAQs and Insights

Conclusion

Maritime inspections are evolving from manual, reactive checks into proactive, AI-driven quality systems. AI Visual Inspection, Automated Visual Inspection, and AI Quality Control provide the accuracy, scalability, and predictive insights needed for today’s maritime challenges.

From hulls and cargo containers to offshore rigs and port cranes, Visual Inspection AI ensures consistency, compliance, and operational resilience. For senior decision-makers, adopting AI inspection systems is not just a technical upgrade, it’s a strategic imperative to secure long-term safety, sustainability, and profitability.

Companies that embrace AI-powered inspections early will gain a decisive competitive edge, positioning themselves as leaders in efficiency, compliance, and innovation across the maritime industry.