Introduction to APM

In today's data-driven world, organizations across industries are increasingly recognizing the pivotal role of their assets in driving operational efficiency, profitability, and sustainability. Asset Performance Management (APM) has emerged as a strategic imperative to optimize asset lifecycle value, minimize downtime, and enhance overall business performance. This blog delves into the core functions of APM, exploring how they empower organizations to unlock the full potential of their assets.

Understanding Asset Performance Management

Asset Performance Management refers to a systematic approach to maximizing the performance, reliability, and lifespan of assets through data-driven insights and proactive maintenance strategies. It encompasses a range of activities, from monitoring and analyzing asset health to implementing predictive and prescriptive maintenance solutions. By leveraging advanced technologies, APM aims to ensure that assets operate at their optimal levels, minimize downtime, and reduce operational costs.

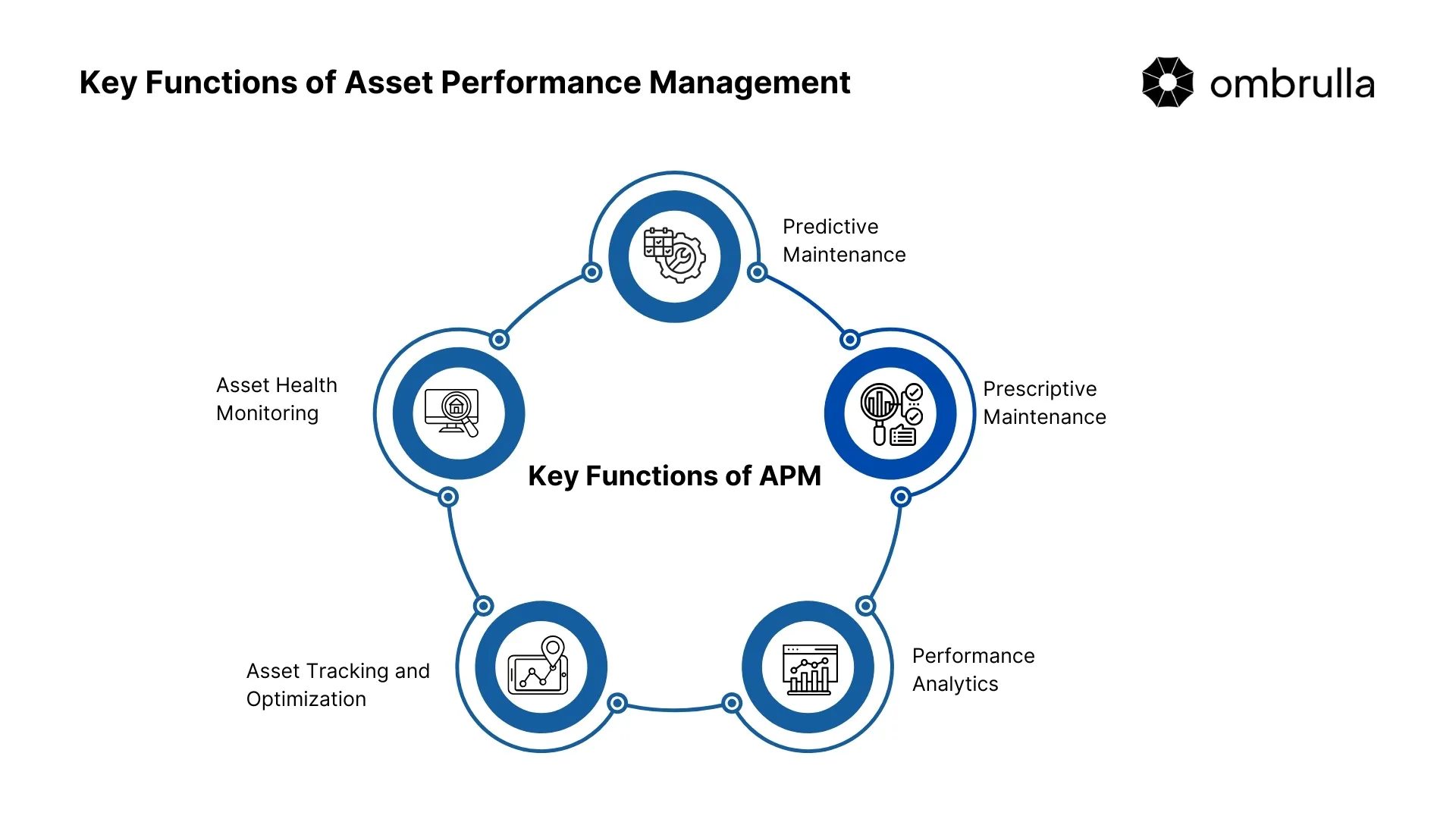

Key Functions of Asset Performance Management

Asset Performance Management (APM) enables real-time monitoring, predictive maintenance, and performance optimization to improve asset health and efficiency. It helps detect issues early, reduce downtime, and enhance asset utilization. APM also provides actionable insights for cost savings and better resource allocation.

1. Asset Health Monitoring

At the heart of APM lies the ability to continuously monitor asset health in real-time. By deploying sensors and IoT devices, organizations can collect vast amounts of data on asset performance parameters such as vibration, temperature, pressure, and energy consumption. This data is then analyzed to identify potential issues before they escalate into costly breakdowns.

- Key Benefits:

- Early detection of anomalies and failures

- Proactive maintenance scheduling

- Optimized asset utilization

- Improved safety and compliance

2. Predictive Maintenance

Predictive Maintenance is a cornerstone of APM, leveraging advanced analytics and machine learning to predict when equipment is likely to fail. By analyzing historical maintenance data, sensor readings, and operating conditions, APM systems can accurately forecast equipment failures, enabling organizations to schedule maintenance proactively.

- Key Benefits:

- Reduced unplanned downtime

- Extended asset lifespan

- Optimized maintenance resource allocation

- Improved operational efficiency

3. Prescriptive Maintenance

Building upon predictive maintenance, prescriptive maintenance offers actionable recommendations for addressing potential equipment failures. By combining predictive analytics with AI, APM systems can not only predict failures but also suggest optimal maintenance actions, spare parts requirements, and even alternative equipment configurations.

- Key Benefits:

- Enhanced maintenance effectiveness

- Minimised repair costs

- Improved asset availability

- optimized maintenance workforce

4. Performance Analytics

APM provides comprehensive performance analytics to help organizations measure and improve asset utilization, efficiency, and reliability. By analyzing asset data, organizations can identify performance bottlenecks, optimize asset allocation, and benchmark performance against industry standards.

- Key Benefits:

- Enhanced decision-making

- Improved asset utilisation

- Increased return on investment (ROI)

- Identification of cost-saving opportunities

5. Asset Tracking and Optimization

Effective asset tracking is crucial for maximising asset value and utilisation. APM solutions enable organisations to track asset location, condition, and usage patterns in real-time. This information can be used to optimise asset allocation, reduce theft and loss, and improve inventory management.

- Key Benefits:

- Improved asset visibility

- Enhanced asset utilisation

- Reduced asset losses

- optimized inventory management

The Role of Industry 4.0 in Asset Performance Management

Industry 4.0, characterised by the integration of digital technologies and smart systems into industrial processes, has significantly impacted asset performance management. The convergence of IoT, artificial intelligence, and big data analytics has transformed traditional asset management practices into more advanced and data-driven approaches. Key elements of Industry 4.0 that influence APM include:

- IoT (Internet of Things):Connects assets and devices to collect real-time data and enable remote monitoring and control.

- Big Data Analytics: Processes large volumes of data to derive actionable insights and improve decision-making.

- Artificial Intelligence: Enhances predictive and prescriptive analytics by learning from data and adapting to changing conditions.

Implementing APM Software

To leverage the full potential of APM, organisations often rely on specialised asset performance management software. These software solutions integrate various functions, such as asset health monitoring, predictive maintenance, and performance analytics, into a unified platform. Key features of APM software include:

- Real Time Data Collection:Aggregates data from IoT devices and sensors for continuous monitoring.

- Advanced Analytics:Provides insights into asset performance, maintenance needs, and optimization opportunities.

- User Friendly Interfaces:Offers intuitive dashboards and visualisations for easy access to data and insights.

Choosing the Right APM Software

When selecting an APM software solution, organisations should consider factors such as scalability, compatibility with existing systems, and the ability to integrate with IoT and IIOT devices. It's also important to evaluate the software's support for advanced analytics, predictive and prescriptive maintenance, and asset tracking functionalities.

Case Studies: The Impact of APM Across Industries

Artificial Intelligence in Manufacturing : Automotive Manufacturer

A leading automotive manufacturer implemented an APM solution to optimise its production line. By leveraging predictive maintenance, the company reduced unplanned downtime by 30% and increased overall equipment effectiveness (OEE) by 15%. Additionally, the ability to track asset utilisation enabled the manufacturer to identify production bottlenecks and improve line efficiency.

Artificial Intelligence in Oil and Gas : Offshore Drilling Platform

An offshore drilling platform implemented APM to monitor the condition of critical equipment, such as pumps and compressors. By using predictive maintenance, the company prevented catastrophic failures, reduced maintenance costs by 25%, and improved safety by identifying potential hazards early on.

Artificial Intelligence in Energy and Utilities : Power Generation Plant

A power generation plant implemented APM to optimise asset performance and reduce maintenance costs. By analysing equipment data, the company identified patterns and anomalies that led to the development of predictive maintenance models. This resulted in a 20% reduction in maintenance costs and improved plant reliability.

Future Trends in Asset Performance Management (APM) Solutions

The field of Asset Performance Management is continually evolving, driven by advancements in technology and changing industry demands. Some emerging trends include:

- Integration of AI and Machine Learning:Advanced AI algorithms and machine learning models are becoming increasingly sophisticated, enabling more accurate predictions and actionable insights.

- Enhanced IoT Capabilities:IoT technology continues to advance, providing more detailed and granular data for asset monitoring and management.

- Increased Focus on Sustainability:Organisations are placing greater emphasis on sustainable practices, including energy efficiency and reduced environmental impact, which are integrated into APM strategies.

Conclusion

Asset Performance Management (APM) optimizes asset performance, reduces costs, and enhances efficiency through health monitoring, predictive maintenance, and analytics. With AI and IoT integration, APM enables real-time insights and data-driven decisions, ensuring businesses stay competitive in a tech-driven world.