Tell us about your challenge - we’re here to help.

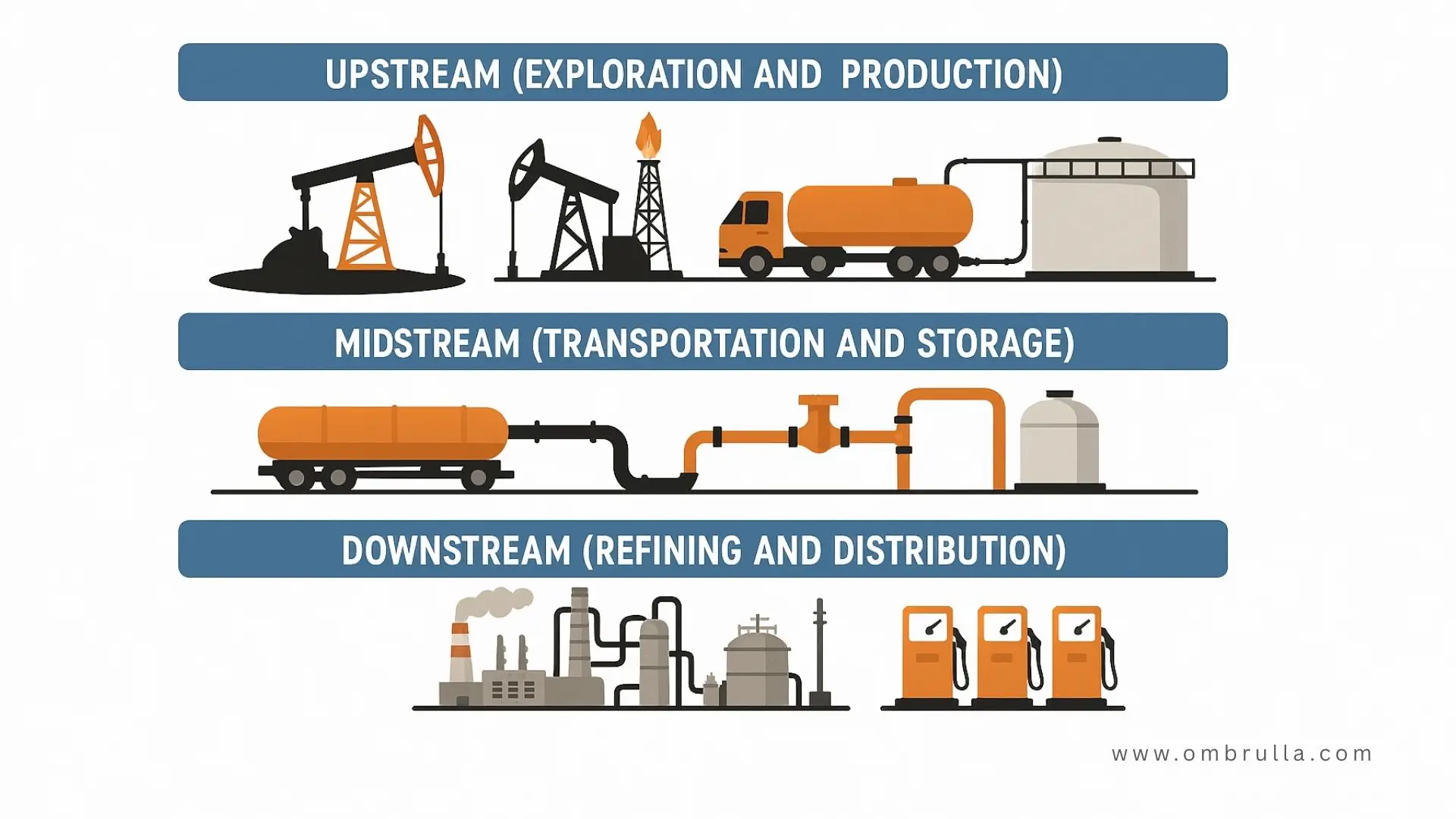

AI Visual Inspection is transforming the oil and gas industry by making inspections faster, safer, and more reliable. By combining artificial intelligence with computer vision, it can detect anomalies in pipelines, storage tanks, and refinery equipment with a level of accuracy and consistency that manual methods often lack. This shift not only improves efficiency but also reduces risks, helping companies prevent costly failures and maintain compliance with strict safety and environmental standards. As the industry embraces digital transformation, automated inspection technologies are becoming central to operations across upstream, midstream, and downstream sectors.

The oil and gas industry faces constant challenges in safety, compliance, and efficiency. AI Visual Inspection automates defect detection across pipelines, storage tanks, and refineries reducing downtime, ensuring compliance, and enabling predictive maintenance. In this blog, we’ll explore how AI-driven inspection is being applied in real-world scenarios, highlight success stories from leading companies, and look at the future trends shaping its role in the energy sector.

Oil and gas industry operations are divided into three interconnected sectors, each facing unique inspection challenges that AI Computer Vision can help address.

This sector involves searching for oil and gas reserves, drilling wells, and extracting hydrocarbons. Upstream operations often take place in remote and harsh environments such as deep seas and deserts. Key challenges include:

Artificial Intelligence Visual Inspection is applied here through drones, subsea robots, and satellite imagery to detect cracks, leaks, and anomalies that could lead to costly downtime.

This stage involves transporting crude oil and natural gas via pipelines, rail, ships, and storage facilities. Major risks include:

Automated Visual Inspection systems help detect small defects before they escalate into catastrophic failures. AI-powered drones can scan vast stretches of pipelines and detect anomalies in real-time.

Here, crude oil is refined into usable products such as gasoline, diesel, and petrochemicals before being distributed. Risks include:

Through AI Quality Control and Defect Detection in Manufacturing principles, refineries maintain consistent product quality while reducing operational hazards driving the digital transformation in refinery inspections.

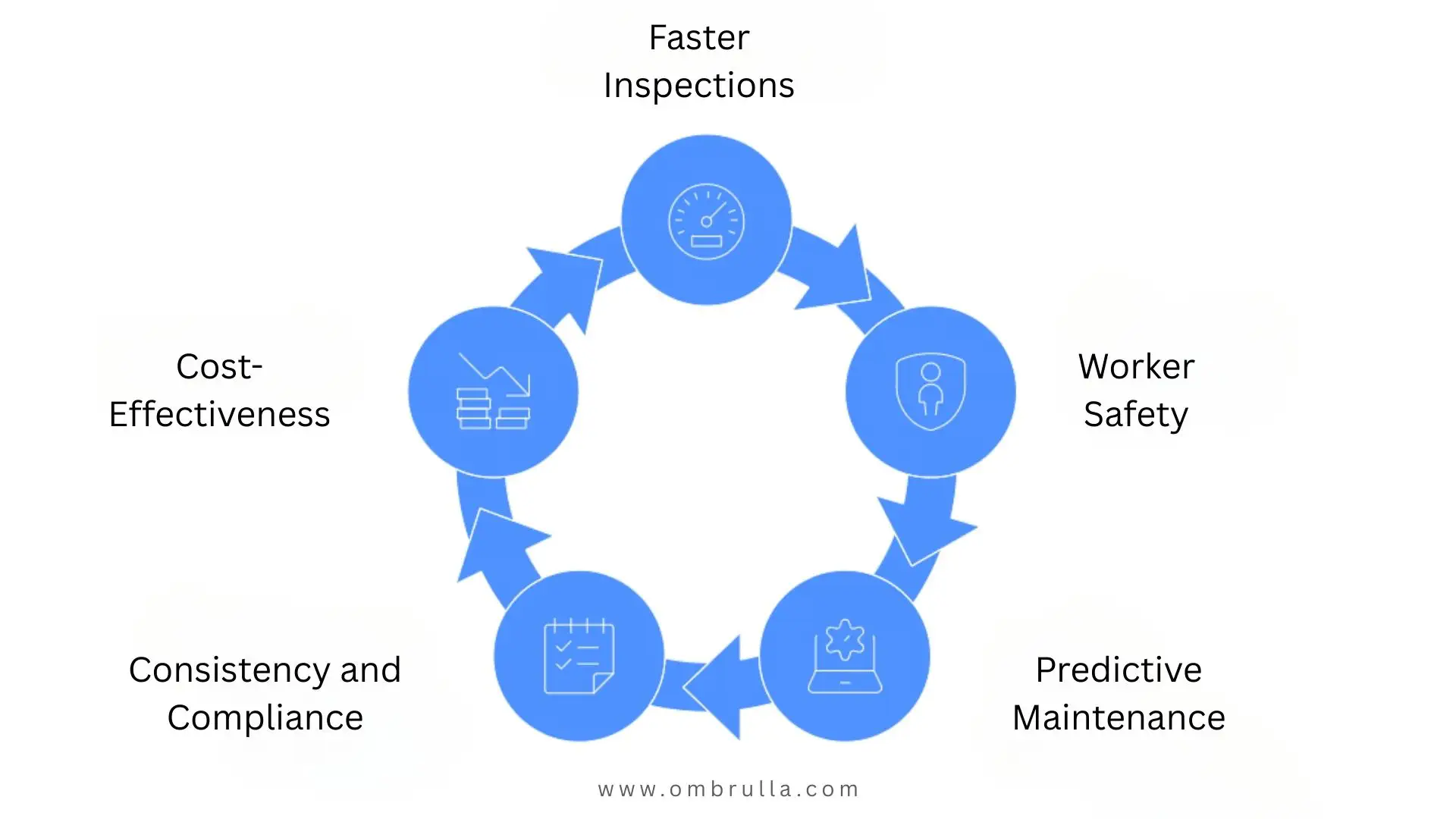

The oil and gas industry faces constant pressure to reduce costs, improve safety, and meet sustainability targets. AI Visual Inspection provides a strategic solution by:

Predictive maintenance powered by AI Defect Detection forecasts equipment failures before they occur.

Replacing human inspectors in high-risk environments with AI-enabled drones and robots.

Reducing manual inspection labor costs and avoiding expensive shutdowns.

Monitoring thousands of kilometers of pipelines simultaneously using AI Inspection Systems.

Detecting leaks early to prevent environmental disasters.

The result is an industry that operates more efficiently, with greater resilience against operational disruptions.

AI visual inspection for pipelines and refineries enables early corrosion detection, preventing leaks and environmental hazards while lowering repair costs. It also improves offshore rig safety monitoring with AI, ensures compliance with oil and gas regulations, and supports predictive maintenance that reduces downtime and extends asset lifespan.

AI-powered Visual Inspection AI can detect microscopic cracks, corrosion, or surface irregularities that human inspectors might miss.

Manual inspection of large offshore rigs or long pipelines can take weeks. With AI Computer Vision, inspections are automated and completed in hours.

Automated Visual Inspection systems reduce human exposure to hazardous environments such as confined spaces, heights, or deep-sea platforms.

Using advanced algorithms, AI Quality Control predicts when equipment is likely to fail, allowing proactive maintenance instead of reactive repairs.

Unlike humans, AI systems provide consistent inspections without fatigue. This ensures compliance with regulatory frameworks and safety standards, making AI a key enabler of AI in oil and gas safety compliance.

Although initial implementation costs are significant, the long-term savings from reduced downtime, fewer accidents, and optimized maintenance are substantial.

The versatility of AI Inspection Systems makes them applicable across multiple use cases in the industry:

Preventing leaks through constant surveillance and enabling predictive maintenance with AI inspections in pipelines to reduce unplanned failures.

AI-powered drones inspect hard-to-reach areas on rigs, detecting cracks, corrosion, and anomalies to enhance safety and reliability.

AI-driven inspections ensure valves, turbines, and pumps remain defect-free, driving efficiency and enabling the digital transformation in refinery inspections.

AI visual inspection detects corrosion, rust, and cracks early, enabling predictive maintenance and extending asset lifecycles.

AI systems monitor helmets, vests, and gloves in real time, ensuring safety protocols are followed and compliance reports are accurate.

AI visual inspection identifies spills and emissions instantly, helping operators prevent environmental damage and strengthen ESG compliance.

By applying Defect Detection in Manufacturing logic, oil and gas companies are adapting proven industrial techniques to their unique environments.

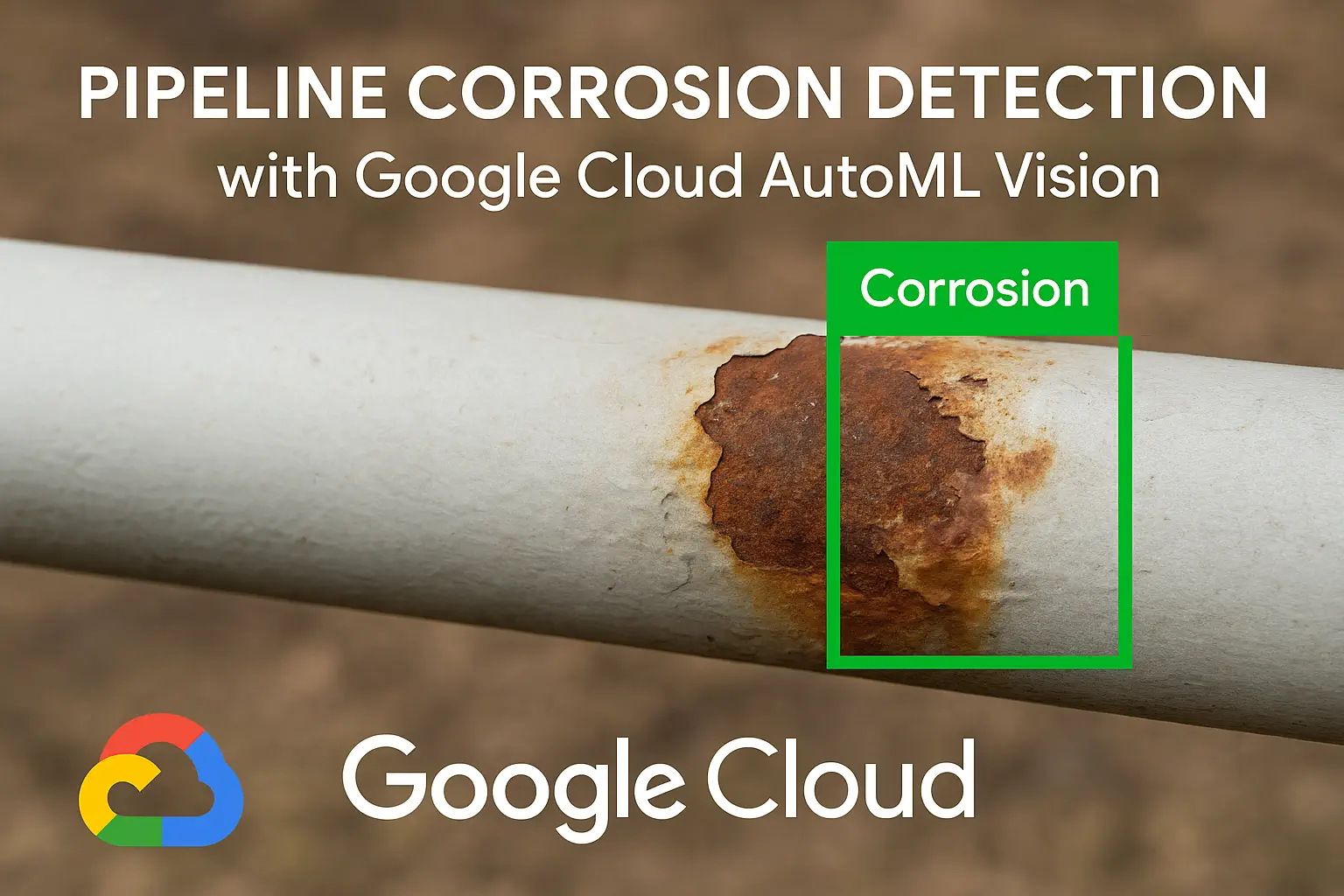

Corrosion is one of the most persistent threats to pipeline integrity. Google’s AutoML Vision offers customizable solutions for AI Defect Detection in this area.

This approach reduces the risk of catastrophic pipeline failures and lowers maintenance costs by detecting defects early.

Early pipeline corrosion detection reduces failure risks, prevents environmental damage, and lowers maintenance costs ensuring compliance and business continuity.

Storage tanks hold millions of barrels of crude oil and refined products, making them critical to operations. Amazon SageMaker provides:

By leveraging cloud-based AI, companies gain scalable, reliable monitoring of vital assets.

Cloud-based AI tank monitoring enables predictive maintenance, reducing downtime while ensuring safety and compliance for critical storage assets.

Worker safety remains a top priority in oil and gas operations. Microsoft Azure Custom Vision provides a robust AI Inspection System for PPE monitoring:

This automated compliance check reinforces a proactive safety culture across worksites.

Automating PPE compliance reduces workplace accidents, strengthens safety culture, and lowers liability risks helping leaders safeguard their workforce and reputation.

Artificial Intelligence is revolutionizing visual inspection across industries, particularly in the energy sector where safety, efficiency, and reliability are paramount. Leading companies such as ExxonMobil, Chevron, and Shell have successfully adopted AI-driven solutions to enhance operational performance and reduce risks. From predictive maintenance to pipeline surveillance and storage tank monitoring, these organizations showcase how AI-powered visual inspection is transforming traditional practices into smarter, data-driven operations.

ExxonMobil has integrated AI Defect Detection across its offshore rigs. The system monitors drilling equipment, turbines, and pumps to detect fatigue or cracks. As a result:

Chevron adopted AI Computer Vision systems to inspect pipelines spanning thousands of kilometers. The system continuously monitors for leaks, corrosion, and unauthorized interference. As a result:

Shell leverages drones combined with Automated Visual Inspection to monitor storage tanks. AI models analyze tank surfaces for cracks and rust, delivering higher accuracy in less time. As a result:

While the benefits are clear, organizations face several barriers to full adoption:

AI models require vast annotated datasets, which may not be readily available.

Upgrading old infrastructure can be costly and complex.

Employees need training in AI and Computer Vision systems.

Increased connectivity raises the risk of cyberattacks.

Differing standards across regions slow down implementation.

Addressing these challenges requires collaboration between technology providers, regulators, and oil and gas operators.

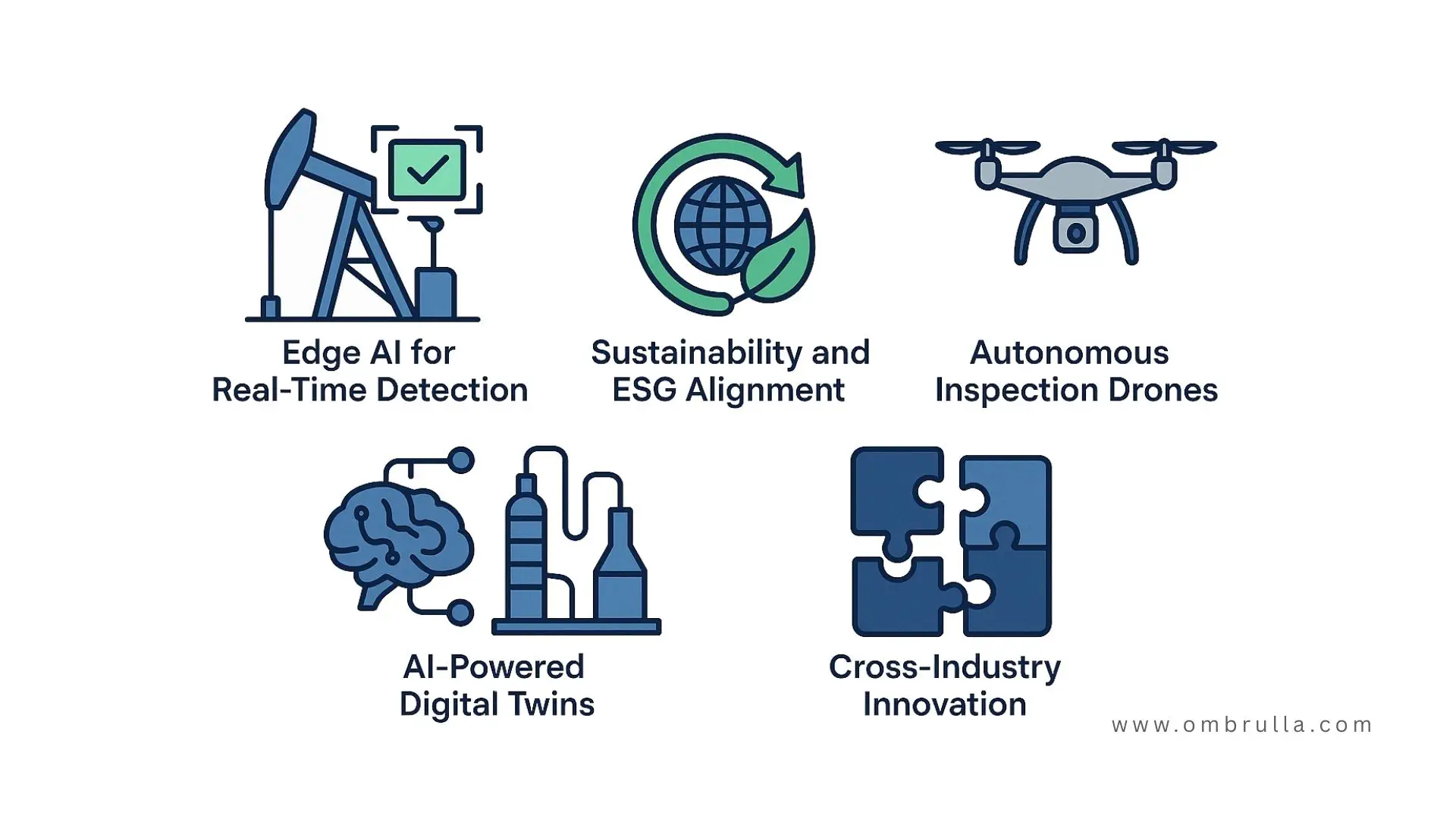

Looking ahead, AI Visual Inspection will evolve alongside advancements in AI and IoT. Key trends include:

Low-latency detection on devices deployed at inspection sites.

AI-powered Quality Control minimizes leaks and emissions, aligning with global sustainability goals.

Next-generation drones will independently inspect offshore rigs, reducing human involvement further.

Creating digital twin replicas of assets for predictive maintenance and risk simulation.

Lessons from Defect Detection in Manufacturing will continue to shape AI inspection systems for oil and gas.

The oil and gas industry is entering a new era of efficiency and safety. Traditional inspection methods, while once effective, can no longer keep pace with the scale and complexity of modern operations. AI Visual Inspection in the Oil and Gas Industry is reshaping how companies monitor assets, protect workers, and stay compliant by enabling faster, more accurate, and more reliable inspections.

From exploration to refining, this technology is setting new benchmarks for reliability and sustainability. Organizations that embrace AI Visual Inspection in the Oil and Gas Industry will be positioned to lead the way toward a safer, smarter, and more efficient future.