Introduction

When teams compare ai visual inspection vs traditional inspection methods, they usually want fewer escapes and less rework without slowing the line. AI inspection stays consistent across shifts, stores proof for each flagged part, and handles normal variation better than manual or rule-based checks, especially on high-volume lines.

Key takeaways:

- •AI reduces shift to shift variation and gives consistent evidence for every questionable part.

- •Traditional checks work for simple defects, but struggle when lighting, surfaces, or SKUs change.

- •Edge deployment can flag defects in milliseconds, then route results to PLC or dashboards.

The Core Comparison AI Visual Inspection vs Traditional Methods

When people search ai visual inspection vs traditional inspection methods, they usually have the same problem: inspection is slowing the line, defects are slipping through, or both. This comparison keeps it simple and practical.

| Criteria | Manual inspection | Rule based vision | AI visual inspection |

|---|---|---|---|

| Consistency | Varies by shift | Stable until conditions change | Consistent |

| Variation handling | Low | Low to medium | Medium to high |

| Throughput | Depends on people | Fast | Fast |

| Changeovers | Easy | Time consuming | Moderate |

| Evidence trail | Low | Medium | High |

| Best fit | Low volume, subjective | Simple, stable defects | Mixed SKUs, subtle defects |

Computer Vision vs Manual Inspection Accuracy and Defect Escapes

Manual checks depend on attention and time. On a busy shift, people speed up, and small defects slip through. That is how escapes happen.

With computer vision inspection vs manual inspection, the key difference is consistency. AI can check every unit the same way and store images for review. That makes audits and customer claims easier to handle.

Rule Based Vision vs AI Inspection Why Variation Breaks Traditional Systems

Rule based vision works when the product and lighting stay predictable. In real plants, they rarely do. A new supplier batch, a slightly different surface texture, glare, or dust on the lens can trigger false rejects.

In ai inspection vs traditional inspection, AI is chosen when you want fewer retuning cycles and better tolerance to normal variation.

Speed vs Precision How AI Balances High Throughput and Accuracy

High speed lines force a tradeoff: inspect less or slow down. AI reduces that tradeoff by inspecting in real time and triggering decisions fast.

If latency matters, edge deployment is often the practical choice. The inspection happens near the station, so you can reject, alert, or route parts without waiting on a network.

The Economic Impact ROI of Automated Quality Control

Most buyers comparing ai visual inspection vs traditional inspection methods want a straight answer: will it save money without slowing the line. ROI usually comes from fewer false rejects, less rework, and fewer escapes reaching customers. If you run multiple shifts, small gains repeat all day and pay back faster.

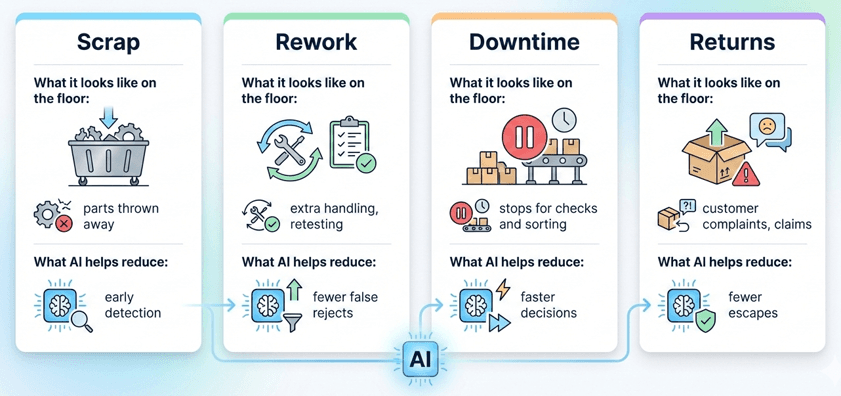

| Cost bucket | What it looks like on the floor | What AI helps reduce |

|---|---|---|

| Scrap | parts thrown away | early detection |

| Rework | extra handling, retesting | fewer false rejects |

| Downtime | stops for checks and sorting | faster decisions |

| Returns | customer complaints, claims | fewer escapes |

Calculating the Real Cost of False Rejects and Rework

False rejects are not just “a few extra parts.” They create queues. Someone pulls the part, rechecks it, argues about borderline defects, and the line loses rhythm. This is where ai visual inspection vs manual inspection often wins, because AI can apply the same standard every time and store proof for review.

Payback Periods What Drives Returns in Multi Shift Plants

Payback is fastest when the line runs long hours and defects are expensive. Multi shift plants repeat the same inspection decision thousands of times a week. If AI reduces rework minutes or prevents a batch of escapes, it shows up quickly in labor, uptime, and fewer customer complaints. That is the real driver in ai inspection vs traditional inspection.

Scaling Without Increasing Headcount The Multi Shift Advantage

Manual inspection scales by adding people, training, and supervision. That also increases variation between shifts. With computer vision inspection vs manual inspection, the main advantage is consistency. The same checks run at the same speed on every shift, and QA can review saved images instead of guessing what happened after the fact.

Industry Evidence What Real Companies Achieve with AI

These examples show what changes when teams move from manual or rule based checks to AI. They are not here to sell you anything, just to make the comparison practical for aI inspection vs traditional inspection.

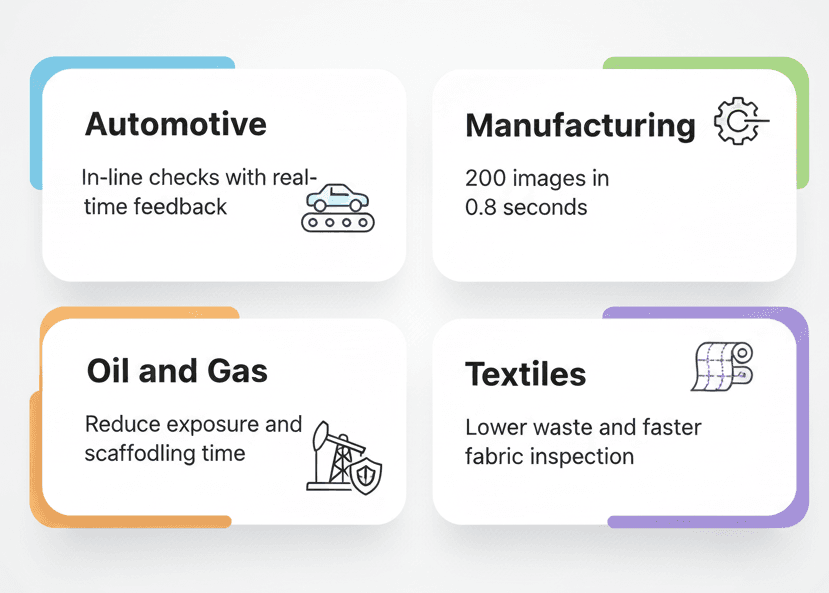

1. Automotive How BMW Uses AIQX for In Line Quality Intelligence

BMW describes AIQX in its iFACTORY, using cameras and sensors to analyze quality in real time and give feedback on the line. It supports checks like completeness and anomaly detection.

For your understanding: Start with one station where escapes are costly.

2. Manufacturing How LG Achieved 0.8 Second High Speed Inspection

A Google Cloud case study reports LG inspected 200 images in 0.8 seconds, using edge hardware due to latency and bandwidth limits. The same case study reports 99.9% accuracy and $20M annual savings.

For your line: If takt time is tight, edge inspection matters.

3. Oil and Gas How Drones Reduce Risk and Improve Coverage

Reuters reports Terra Drone’s work with Saudi Aramco to support drone inspections and reduce time consuming manual checks that can require weeks of scaffolding.

For your site: Use visual evidence to prioritize risky work.

4. Textiles How AI Handles Moving Web Defects at Line Speed

Uster notes that automated fabric inspection, depending on setup, can deliver up to 50% lead time savings and 80% less waste by combining inspection with usable data. They also position automated inspection as the starting point for using inspection data more intelligently across production.

Ombrulla mini case: A textile unit was finding defects late because checks happened after production, so sorting and rework piled up.

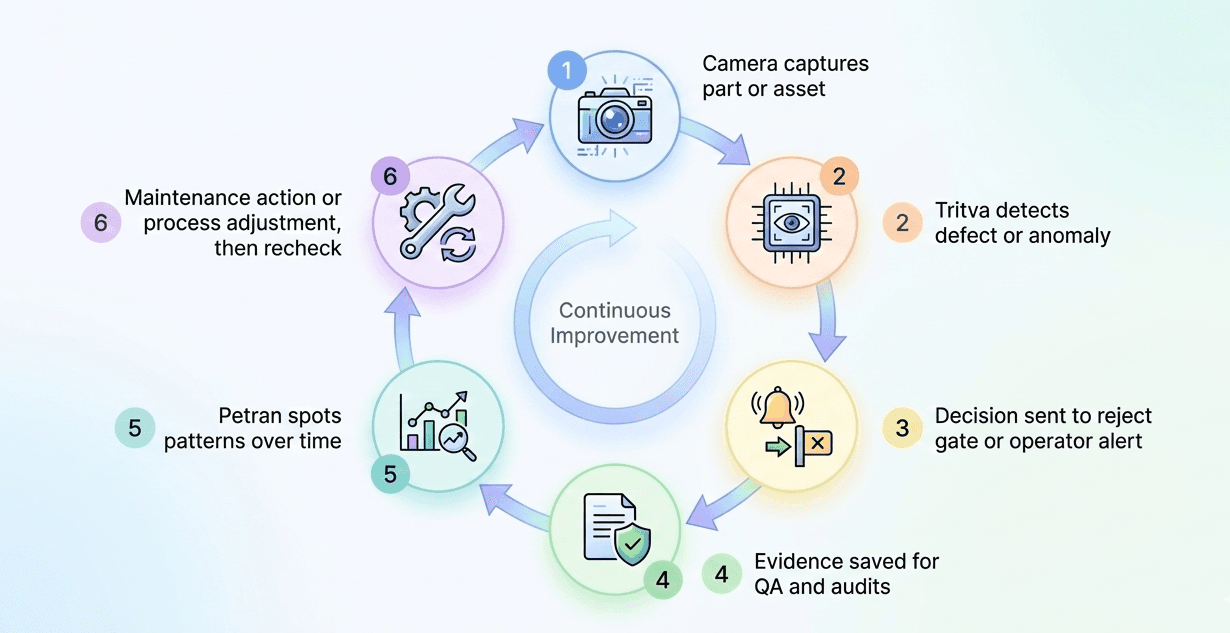

We used Tritva for in-line detection and a defect map per roll, so supervisors could see what changed during the shift. Then Petran tracked recurring defect patterns and helped the team act earlier on machine and maintenance triggers.

Supervisors could see exactly when defects started, so they fixed the machine sooner.

The Technology Edge How Petran and Tritva Redefine Inspection

In ai vs manual inspection, the goal is not only to spot defects. It is to decide fast, keep proof, and reduce repeats. Tritva handles real time inspections near the line. Petran helps turn repeated defect patterns into a maintenance or process fix.

1. Why Edge AI Tritva Matters for Zero Latency Production Lines

When the time allowed per part is tight, inspection cannot wait on a network. Tritva runs at the station, triggers a reject or alert instantly, and stores evidence for QA.

2. Closing the Loop Linking Visual Quality to Predictive Maintenance Petran

Defects often spike before a breakdown. Petran tracks inspection trends and helps teams act early, so you fix the cause instead of sorting parts shift after shift.

Where Traditional Methods Still Make Sense The Balanced View

Not every line problem needs AI. When people compare ai vs manual inspection, the best answer is often: use the simplest method that meets quality, speed, and audit needs. Traditional checks still work well in a few common situations.

1. When Manual Inspection Is Still Practical Low Volume and Prototypes

If you are building prototypes or running small batches, manual inspection is usually faster to start and easier to change. It also makes sense when the defect is subjective, like a cosmetic grade that depends on customer expectation. In those cases, ai visual inspection vs manual inspection is less about accuracy and more about whether automation is worth the effort yet.

2. When Rule Based Vision Is Enough for Simple High Contrast Defects

Rule based vision is fine when the check is simple, like presence or absence, clear marks, or basic measurements.It works best when lighting and part position stay consistent, so you are not retuning settings every time something changes.If you are constantly adjusting thresholds, that is usually the sign to consider ai inspection vs traditional inspection for that station.

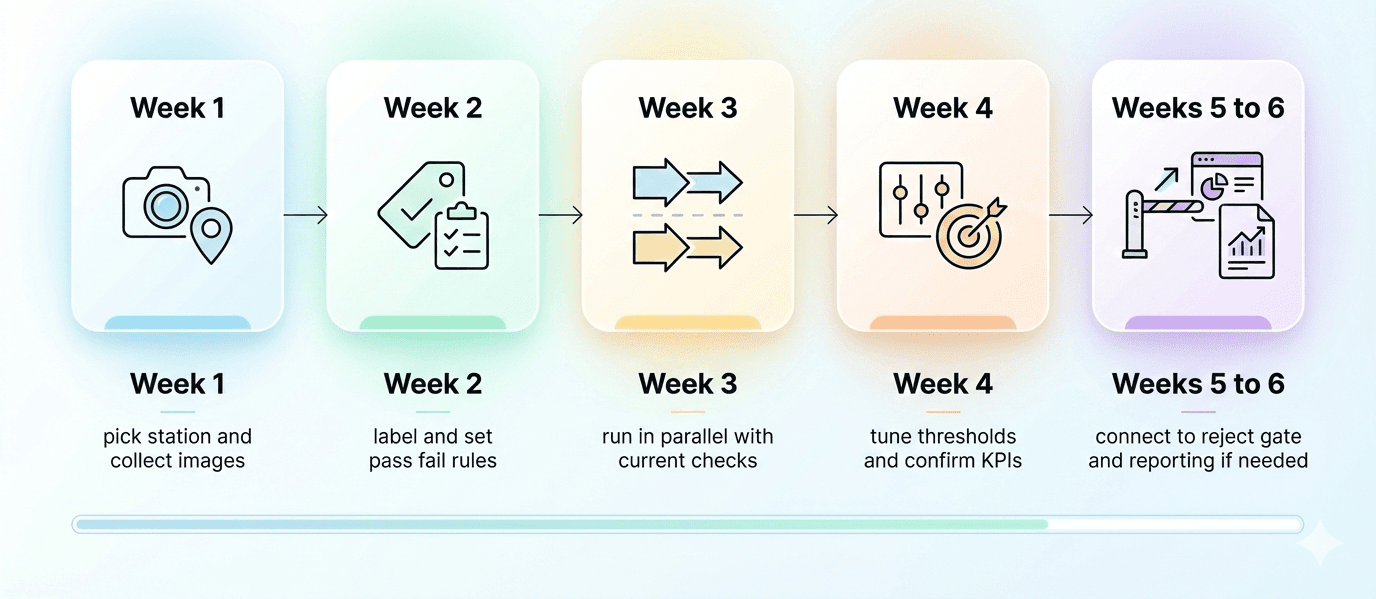

Implementation Strategy Moving from Manual to Automated Inspection

Do not replace everything at once. Start with one inspection point, prove results, then expand. This is the safest way to compare ai visual inspection vs traditional inspection methods on your own line.

1. How to Pick Your First Quick Win Inspection Station

Choose a station where rework or sorting happens every shift. Pick one defect type that is easy to confirm. That is the quickest proof for computer vision inspection vs manual inspection.

2. Success Metrics KPIs QA and Operations Leaders Actually Care About

Track escapes, false rejects, and rework minutes. Add one more check: does it slow the line. If these improve, ROI is real.

3. Data Privacy and Security Deploying AI in Regulated Environments

Decide where images stay: edge or on prem if rules are strict. Keep access limited and logged. Store only what you need for traceability.

4. Integration Check PLC MES and SCADA Readiness

Decide the action first: reject, alert, or hold. Connect that to PLC signals for the pilot. Add MES or SCADA reporting after the station is stable.

Frequently Asked Questions

References

- BMW Group, AIQX overview[bmwgroup]

- Google Cloud, LG manufacturing case study PDF[googlecloud]

- Uster press release on automated fabric inspection[uster]