Introduction

AI Visual Inspection uses high quality cameras and deep learning models to find defects instantly on the production line. It also helps manufacturers identify errors early, improve inspection quality, reduce rework cost and maintain quality consistently.

What Is AI Visual Inspection and Why Is It Needed Today?

The AI Visual inspection system uses advanced cameras and deep learning methods to detect defects during production. It makes inspection fast, accurate, and repeatable inspection.Most manufactures use it today to improve product quality, minimize errors and be faster in the modern production demands.

Traditional visual inspection methods will heavily depend upon manual inspection methods which vary from person to person and become less reliable as production speeds increase.Hence AI visual inspection overcomes these limitations by analyzing every product frame-by-frame with accurate precision. It even spots tiny defects that humans miss, maintain accuracy even during long shifts, and generate real-time insights that help teams make faster decisions. As companies try to produce more products with with no mistakes, AI-based inspection has become a must-have tool for ensuring good quality

Why Is AI Visual Inspection Used for Quality Control and Defect Detection?

AI visual inspection is used because it can identify defects faster and more accurately than manual inspection It even finds tiny errors that people miss, which works consistently without getting tired than manual inspection and helps manufacturers produce high quality products even in production speed increases.

The Real Problems Manufacturers Face Today

Manufacturers still struggle with several quality inspection problems:

- •Manual inspection is slow

- •People can miss defects

- •Hard to scale with higher production

- •Human fatigue reduces accuracy

- •Judgments vary between inspectors

- •Micro or hidden defects go unnoticed

- •Some inspection tasks are unsafe

- •Defects lead to costly recalls

- •No traceability or useful analytics

These are the obstacles to how fast and well a factory can work. Missed or late detection of these defects result in loss production, lower quality and costly rework, scrap or recalls. It also makes it harder to maintain quality across standard levels if human inspectors are receiving mixed results. Without data or traceability, manufacturers are unable to determine the source of defects in their process and address them, causing impacts on output, customer sat and that oh so sacred bottom line.

How These Problems Affect Throughput, Quality & Cost

When inspection issues are left unaddressed, factories see slower throughput, more defects and higher production costs. Missed issues lead to rework and scrap, Quality becomes inconsistent, and Safety risks expand. Without this data, teams can’t prevent issues early and instead are left with delays, lost efficiency, and expensive quality failures.

How AI Visual Inspection Works

AI Visual Inspection uses high quality advanced cameras in different angles to capture images of each product in different angles and use deep learning models to analyze them in real time. AI compares what it sees with thousands of examples and instantly identifies anything that looks unusual, damaged, or out of place. This makes defect detection fast, accurate and consistent.

Step 1: Image Capture With Industrial Cameras:

AI Visual Inspection works with high speed industrial cameras which captures high quality images and videos for each and every product in the line. These cameras work under different lighting conditions and identify errors that the human eye misses.

Step 2: Real-Time Processing & Deep Learning Analysis:

The system analyses each image using a deep learning method which understands how a product should look like. It checks everything including shape, color, texture and patterns and detects anything which doesn’t match expected standards in real time defect detection.

Step 3: Automated Defect Detection & Classification:

After analyzing, ai automatically identifies and classifies errors such as scratches, dents, misalignments and missing components, Each issue is identified accurately and consistently.This allows manufactures to maintain reliable quality checks every shift and ensure no defects will be caught before reaching customers.

Step 4: Instant Alerts, Sorting, and Quality Decisions:

When a defect is found the system immediately alerts operators or Begins sorting automatically. This real-time response prevents defective products from moving further down the line. So teams can act instantly, it reduces rework , avoids downtime and maintains high productivity without sacrificing quality or efficiency.

Step 5: Continuous Learning With AI Models:

AI models also get better over time and it is “learning from the new images, as well as the production data. The more patterns they encounter, the better they get at perceiving even small disturbances and adapting to different materials or designs of products. This evolution over time results in better reliability long-term and enables manufacturers to construct a smarter, more efficient quality control system.

Why AI Visual Inspection Is Better Than Manual Inspection

AI Visual inspection is much better when compared to manual inspection as it operates really quick, identifying small defects and delivering consistent accurate results. Unlike human checker that must get tired or overlook details, Our Ai check every single product equally and continuously in real-time. This minimizes errors, it saves money and ends up producing higher quality work.

AI vs Manual Inspection: A Practical Comparison Table

| Criteria | Manual Inspection | AI Visual Inspection |

|---|---|---|

| Accuracy | 70-80% | 95-99% |

| Speed | 10–20 parts/min | 100-300 parts/min |

| Consistency | Varies by person | Always consistent |

| Defect Detection | Misses micro-defects | Defect tiny & hidden defects |

| Cost of Quality | High | 20-50% lower |

| Throughput | Slow production | Upto 30% faster |

| Error Rate | High | Up to 90% fewer errors |

What Manual Methods Can’t Detect, but AI Can?

AI Visual inspection method can identify small defects where the human eye can’t like micro-scratches, hairline cracks, subtle color shifts, texture variations, and small misalignments.It also spot fast-moving defects that manual inspectors often miss on high-speed production lines. With advanced imaging and deep learning, AI delivers accurate, consistent detection and provides complete traceability for every inspection. This helps manufacturers avoid defects reaching customers, reduce fixes, and ensure stronger reliability than human checks alone.

Real-Time Decision Making With Zero Fatigue

AI Visual Inspect makes fast decisions in real time without getting tired. It analyses every product with Consistent accuracy, no matter how fast the line moves. This allows manufacturers to react immediately to defects, quality control and make sure production runs smoothly 24/7.

Unlike human inspectors, who inevitably get sloppy after working long shifts, AI remains equally exacting 24/7. Each frame and each product, every detail is always compared with high accuracy in a consistent way for instant quality decisions. For CEOs and heads of operations, that means fewer disruptions, fewer surprises on the shop floor and a more predictable, reliable manufacturing process.

Benefits of AI Visual Inspection With Quantifiable Results

AI Visual Inspection delivers measurable results across production. It increases defect detection accuracy, cuts downtime, lowers the quality cost and gives steady performance 24/7.With automatic analysis and live insights manufactures can identify defects faster and maintain consistent quality across every shift and production batch.

Industry Applications: Where AI Visual Inspection Delivers Impact

AI Visual Inspection is used in a wide range of industries where precision, efficiency and quality are major issues. It assists in detecting defects in automotive parts, electronics, metal surfaces, packaging materials, textiles and battery components. Automation for quality inspection not only minimizes human errors and increases the reliability, but also adopts high production manufacturing with less human touch by AI.

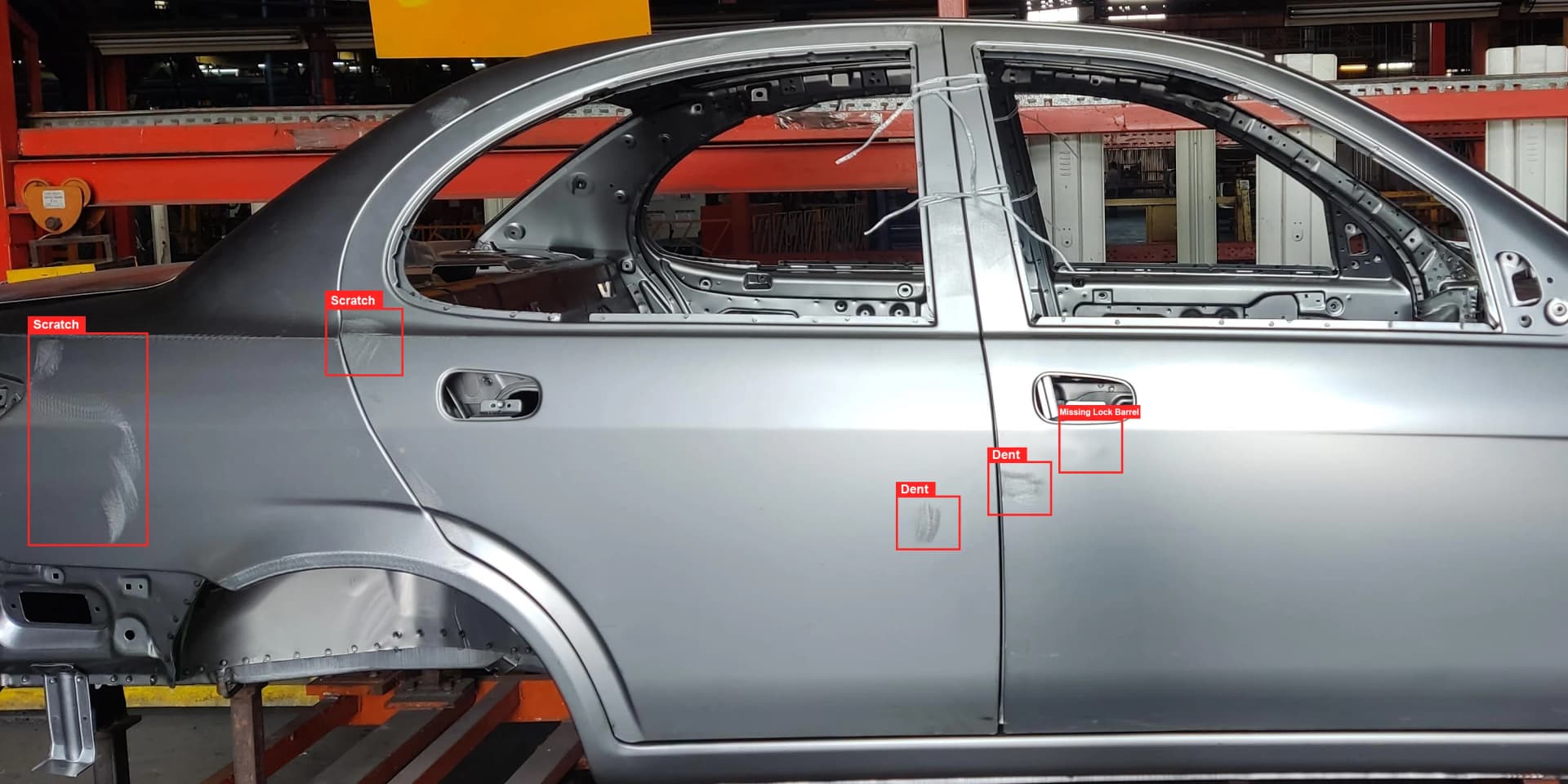

How AI Detects Paint Defects in the Automotive Industry

AI detects paint defects in cars by using high quality cameras at different angles to scan every part and deep learning models to find tiny errors like scratches, dust marks, color variations, or uneven coating. It checks each vehicle consistently, without missing any details, helping people maintain perfect finishes and customer complaints.

| Challenge | AI Solution | Outcome |

|---|---|---|

| In car plants, it is difficult to spot small paint defects dust particles, micro-scratches or an uneven coat as they are virtually invisible to the human eye, particularly when cars are moving at speed along production lines. | AI Visual Inspection employs high-resolution cameras and deep-learning models to examine all painted surfaces in real time. It will pick up even minor flaws right away, long before they are taken to the next level. | For manufacturers that means less rework, defects stopped before they reach the customer and that perfect paint finish across all vehicles. This results in better quality, less complaints, and enormous cost savings. |

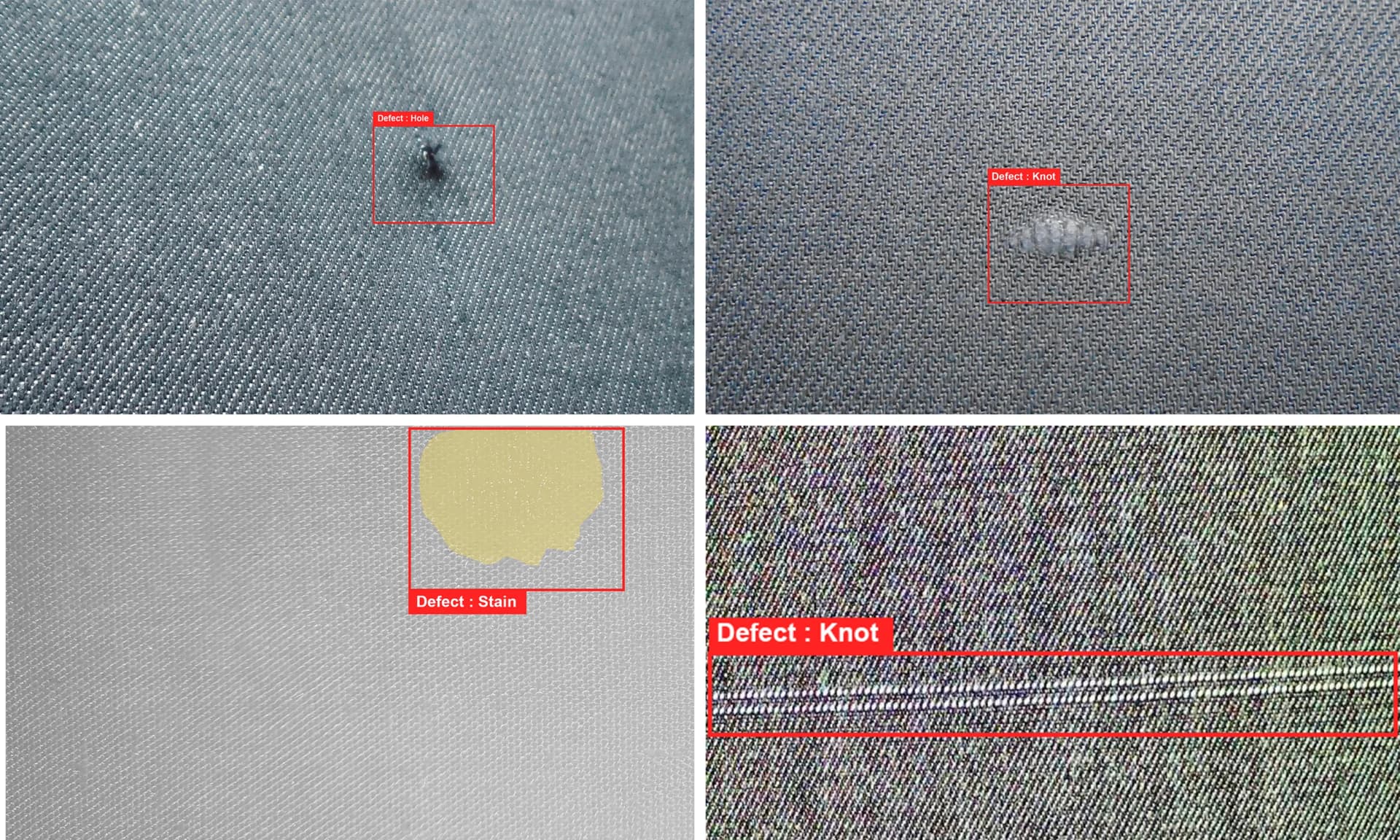

How AI Improves Fabric Defect Detection in Textile Production

AI improves fabric defect detection by analyzing fabric in real time and identifying tiny errors like misweaves, holes, stains, color variations, and pattern irregularities. It works fast and maintains the same level of accuracy during long shifts, helps textile mills reduce waste, improve quality, and maintain consistent production output.

| Challenge | AI Solution | Outcome |

|---|---|---|

| Textile manufacturing is in a hurry, and human inspectors frequently overlook tiny defects misweaves, thin spots, stains, pattern discrepancies. These flaws do not become apparent until some subsequent time, resulting in large masses of discarded cloth and expensive reworking. | AI Visual Inspection employs machine vision cameras that continuously check fabric as it runs through the line. Deep-learning models spot even the slightest variances in colour, weave pattern, texture or alignment and notify operators immediately. | Textile manufactures ensures early defect detection, reduces material wastage and increases quality consistency from batch to lot.. This results in increased customer satisfaction lower for returns and greater predictability in production performance. |

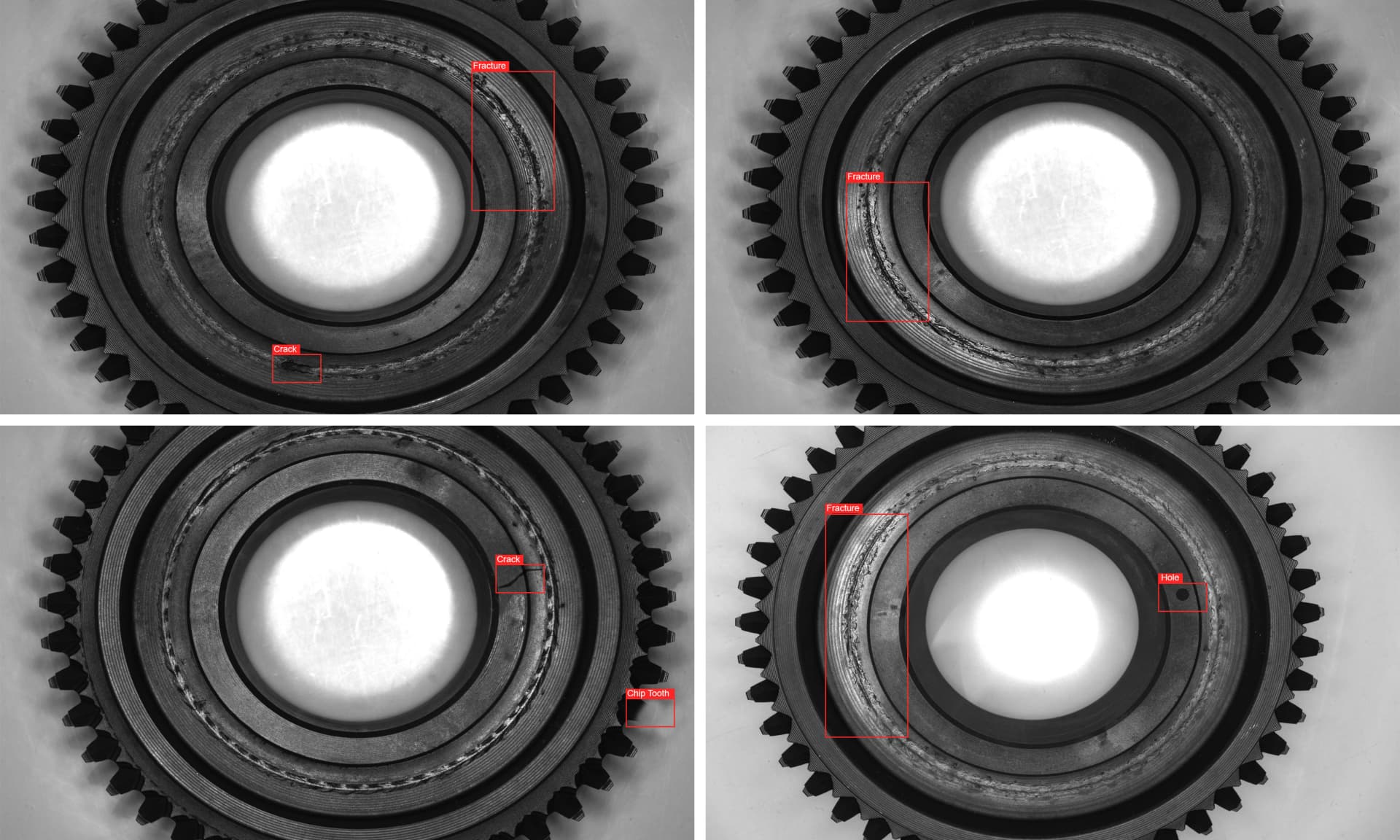

How AI Identifies Anomalies in Mechanical Components

AI detects mechanical defects by comparing high resolution images of mechanical parts and identifying early fatigue, cracks, wear and corrosion. It examines each of the parts with uniform accuracy and detects problems on-the-fly, helps manufacturers avoid shutdowns, reduce downtime and keep critical equipment up and running.

| Challenge | AI Solution | Outcome |

|---|---|---|

| Mechanical parts may have tiny cracks, wear marks, or micro misalignment that a human inspector can overlook. Unresolved issues can lead to catastrophic failure, downtime, safety hazards, repair costs and more. | Advanced Component AI Visual Inspection In real time, a component is examined by deep-learning algorithms through high level imaging methods. It identifies microcracks, surface defects, irregular wear patterns or geometric deviations long before they develop into serious issues. | Manufacturers get ahead of mechanical problems to avoid equipment failure and prolong the life of components. The result is increased production, lower maintenance costs, and safer and more reliable operation. |

How AI Inspects Battery Cells and Packs in the Energy Sector

AI inspects batteries cells and packs by inspecting each layer and surface in detail with high-quality cameras. It hunts for problems like misalignment, tiny wrinkles, dirty bits or an improperly sealed sealing as they occur. This enables manufacturers to detect hazardous defects early, maintain safety and ensure every battery adheres to rigorous quality standards.

| Challenge | AI Solution | Outcome |

|---|---|---|

| Battery cells are extremely touchy, and even tiny defects such as misalignment of electrodes, minuscule particles, folds in the separator or inadequate sealing can result in overheating or performance loss or endanger safety. These are often quite difficult for manual inspectors to see and frequently can be overlooked during high-speed manufacturing. | Every battery cell, and even pack, is scanned layer by layer using accurate machine vision and deep-learning model that is AI Visual Inspection. It detects micro-defects, foreign substances, sealing deficiencies and alignment discrepancies on-the-fly even at high production speeds. Abnormal conditions are immediately identified by the system for countermeasures. | Get safer products, prevent costly recalls, and help ensure all batteries meet stringent safety and compliance requirements. The effect of this is increased reliability, improved performance, extended battery lifetime and reassurance for both customers and regulatory authorities. |

How AI Finds Defects in Bottling and Packaging Lines

AI visual inspection detects defects on bottling and packaging lines & checks every bottle or pack in real time with high-speed cameras and deep-learning models. It can reject cracked bottles, wrong caps, underfilled product, misaligned labels instantly. This allows manufacturers to maintain consistent quality, prevent recalls and run lines more efficiently.

| Challenge | AI Solution | Outcome |

|---|---|---|

| Human inspectors struggle to catch tiny problems, such as chipped bottles, or wrong caps on containers or label misalignment or fill levels that are all off-specification speeds. | AI scans each bottle in real time, and spots defects immediately with high-speed cameras and deep-learning models. | Reduce errors and recalls, increase quality all with dependable consistency. |

How AI Detects Surface Defects in Metal and Steel Manufacturing

AI detects surface defects in metal and steel by analyzing sheets, coils, and components with high-resolution line-scan cameras. It detects defects like scratches, cracks, pits, scale, and edge defects in real time. This helps manufacturers maintain their quality level, reduce scarp, and keep production lines running at their best.

| Challenge | AI Solution | Outcome |

|---|---|---|

| Microcracks, pits and surface imperfections on metal and steel are difficult for people to see even in the best conditions, especially on fast or harsh production lines. | AI looks at every surface in real time with high-resolution cameras and instantaneously flags defects. | But scrap is minimized, quality failures are sidestepped and metal product is consistent and of high grade. |

How AI Visual Inspection Supports Digital Transformation Goals

AI Visual Inspection helps digitalize quality checks and transforms them into a quick, automatic and data-driven operation. It provides streaming production visibility, prevents mistakes from human error, and enables faster decision making by teams. By collecting precise quality data, AI supports manufacturing organisations in increasing efficiency, solidifying compliance and continuing to advance towards fully connected smart factories.

Higher Productivity & Predictable Output

AI Visual Inspection helps keep production teams moving faster without frequent stops. By spotting defects early and providing immediate feedback, it helps keep the line flowing smoothly and consistently. Leaders receive consistent output, a reduced number of surprises and less variation in the manufacturing process to realize long-term growth.

Performance Visibility Through Analytics

With AI, it becomes all quantifiable. All defects, trends, and process variation is recorded automatically and turned into clear insights. That gives management clear visibility into what’s happening on the floor, so it can make smarter decisions, mitigate risks and keep improving overall performance.

Workforce Optimization Without Dependency on Skilled Labor

AI releases the burden from experienced inspectors to deal with repeating competitive tasks which require accuracy. Teams can concentrate on higher value work instead of doing manual checking. This enables manufacturers to address manpower shortages, cut equipment training duration and yet deliver quality output without a heavy dependence on specialized skills.

Implementing AI Visual Inspection: A Practical 5-Step Adoption Framework

Before moving into model selection and deployment, manufacturers should understand how to choose the right AI visual inspection system based on their production speed, defect types, and integration needs.

To implement AI visual inspection in your business, you’ll need to follow five key frameworks they are:

Define Inspection Goals

Begin by identifying exactly what types of defects are most important and how they impact your product quality. Consider whether inspections should take place in real time on the line or after the product is finished. You’ll also need to figure out how AI will fit into your workflow. will it replace manual inspection, augmenting your team, or interfacing with systems such as SCADA and MES?

Collect and Annotate High-Quality Data

Use with RGB, thermal or infrared cameras to capture the various images AI needs to learn from varies lighting. Then annotate every defect specifically, with a tool like CVAT or LabelImg. Clean, organising and improve the data with normalization and augmentation, structure it in COCO format or YOLO to be ready to be trained.

Choose the Right AI Model

Choose an AI model that fits your inspection goals. If you need it fast, YOLOv8 is a good option; if detailed accuracy is worth more than efficiency, EfficientDet or Mask R-CNN will be strong performers. You can also fine tune these models by training them yourself, or using platforms like SageMaker or AutoML. If the system is running on the factory floor, it needs to be optimized for edge hardware.

Validate With Real Production Data

After you train, you test your model with some real production data to make sure is doing what it should. See how well itidentifies defects, and how many mistakes it makes. Rinse and repeat the levels of tuning until the AI can reliably be trusted in real life.

Deploy, Monitor, Improve

After your machine learning model is trained, it can be deployed to the edge or cloud depending on your deployment needs. Pay close attention to how it does in actual production. Train or retrain the model using the insights you gain, so that it continuously becomes better at finding newly discovered defects.

What Makes Ombrulla an Expert in AI Visual Inspection?

Ombrulla is the AI Visual Inspection expert, simply because it brings together a deep experience in computer vision, machine learning and automated defect detection with a track record of industrial deployments. Their AI-driven solutions provide industry leading accuracy, real-time insights and actionable intelligence across a wide range of sectors including manufacturing, automotive and energy – enabling the world's largest enterprise companies to reduce waste and increase product quality.

Proven Experience in Industrial AI Deployments

Ombrulla deployed AI visual inspection systems in the actual production of Automotive, Manufacturing, Packaging and Energy industries. They're experienced because they know what it's like to tackle real-world factory floor challenges: high-speed lines, changing light conditions, challenging part surfaces, or demanding accuracy requirements. This practical deployment experience means that each and every solution can be relied upon to work well in genuine industrial environments.

Advanced Machine Vision & Deep Learning Capabilities

The Ombrulla team is experienced in developing deep learning models that can identify small defects, analyze difficult to describe textures and adapt to changing production patterns. bineye’s capabilities in machine vision, including high-resolution imaging, customized model training and real-time processing that provides cutting-edge accuracy for defect detection with any material and product type.

Hardware + Software Integration Expertise

Ombrulla knows that AI does not stand alone, it must be connected to the existing systems in the factory. They work with industrial cameras, edge devices, PLCs and production software such as SCADA or MES for seamless communication and reliable performance.This hardware–software expertise enables deployment of AI while not intervening with existing workflows

Strong ROI Delivered Across Multiple Industries

Their solutions are tailored to improve KPIs better detection, less rework, scrap reduction and predictable output. Across industries, these advances mean clearer cost savings, fewer quality escapes, and a more reliably smooth operation, offering leadership an impressive ROI on their AI investment.

End-to-End Support From Assessment to Deployment

Ombrulla facilitates support at every step of the AI adoption journey, from identification of inspection needs and collection of data to training the model and deployment on a production line. They continue after the deployment, monitoring performance, tweaking models, making certain that the system continues to deliver on its promises as real-world results unfold.

FAQ’s

Final Thoughts: The Future of Smart Quality Control

The future of quality control belongs to systems that are smarter, faster and entirely data driven. Based on computer vision, machine learning and automated defect detection AI Visual Inspection becomes an integral part of modern manufacturing. With faster production lines and higher customer expectations, companies now can no longer afford to only manually check.

AI provides manufacturers the ability to find defects as they appear in real time and both reduce mistakes and keep product quality consistent from shift to shift. Through intelligent AI models that offer deep dive insights and predictive analytics, along with the seamless integration with digital systems, AI powered inspection supports long-term digital transformation and the ability to compete in quality driven market.

Businesses that invest in intelligent visual inspection, AI for quality control and smart inspection systems today will be better prepared to provide increased reliability, lower costs and more predictable operations tomorrow. The transition is already occurring and AI is creating a new standard for smarter, safer, more effective manufacturing.